Quantum technology and AI: the key to safe second-life applications for lithium-ion batteries

Innovative rapid test method for precise determination of battery condition for industrial use

To promote the sustainability of electromobility and enhance resource efficiency, upcycling of lithium-ion batteries is gaining increasing importance. Efforts are focused on slowing down material cycles by repurposing used batteries from electric vehicles for new applications instead of transferring them directly to recycling processes. Despite its real significant potential to conserve resources, upcycling has yet caught on due to technical and economic challenges. However, a team of researchers has developed a practical method that combines a high-speed measurement method and artificial intelligence (AI) to overcome these barriers.

Is it possible to efficiently and safely reuse batteries from electric vehicles, and what technical and economic challenges need to be overcome? This question is in the focus of the "QuaLiProM" research project funded by the German Federal Ministry of Education and Research (BMBF). An interdisciplinary project team has taken on the scientific objective of determining the residual power and remaining service life of used lithium-ion batteries in a non-destructive, fast and safe manner. Their goal is to enable a reliable and economically viable approach to secondary use of battery cells, paving the way for sustainable battery upcycling.

How healthy is a battery? State of the art and existing challenges in determining condition

Lithium-ion batteries degrade over time both during storage and operation. This degradation manifests itself as a loss of capacity and an increase in internal resistance leading to a gradual decline in energy output and overall performance. The health state of a battery is typically defined using the State-of-Health (SoH), a parameter that describes the extent of cell aging relative to its original state.

Accurate determination of SoH is critical for assessing battery performance and estimating its remaining service life. However, achieving this presents several challenges, which are currently addressed through various experimental methods. Electrochemical measurements, such as cycle tests or electrochemical impedance spectroscopy, are commonly used to determine key metrics like residual capacity and internal resistance in aged cells. However, these methods are limited in significance without reference to the initial performance values of the new cells. Furthermore, such techniques require direct electrical contacting of the cells, making them unsuitable for rapid diagnostics. In addition, this traditional testing approach only provides information on the global condition of the cell, without the ability to pinpoint localized defects or charge hotspots.

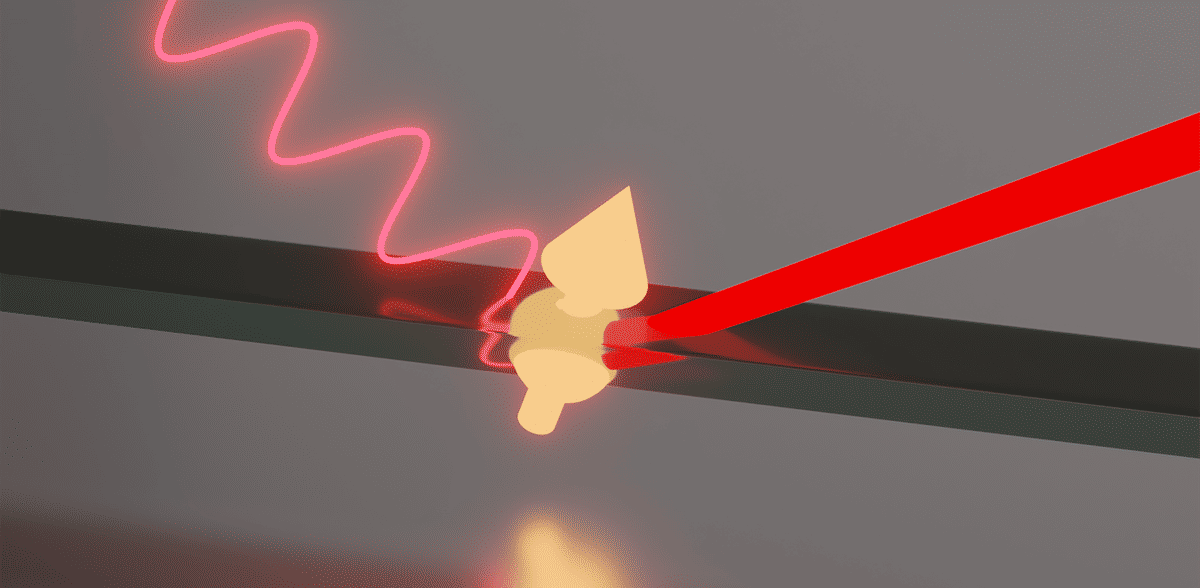

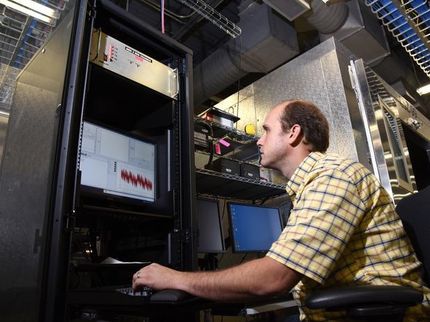

In contrast to these conventional methods, atomic magnetometry offers a breakthrough approach for fast, cost-effective, and precise SoH determination of lithium-ion cells using diamond-based quantum sensors. In the field of battery research, it has already been demonstrated that this method can accurately measure condition-dependent magnetization of battery cells. In particular, quantum sensors have shown the capability to detect defects, impurities, and the state of charge. Based on these promising findings, the "QuaLiProM” project focused on the development of a high-speed measurement method that integrates atomic magnetometry with AI. The goal is to enable the classification of battery cells by their SoH for industrial applications.

Innovative rapid test method for precise determination of battery condition for industrial use

To develop the rapid test methodology, the “QuaLiProM” project subjects lithium-ion cells to accelerated degradation through cyclic aging tests. The electrochemical measurement data collected during these tests serves as database for identifying dominant aging mechanisms. By recording and evaluating this data, precise insights can be gained into the condition and remaining performance of the cells. The aged battery cells are then further examined using atomic magnetometry. The quantum sensor employed in this testing method, measures the magnetic field of the cells with high precision by observing the spin of a nitrogen vacancy center in a diamond. This defect emits varying numbers of light particles depending on the surrounding magnetic field. These mappings are providing valuable information about potential anomalies in the battery cells. This non-destructive method does not require time-consuming charging and discharging cycles, making it highly suitable for integration into cell production processes, as well as for recycling or upcycling applications. One of the project’s primary goals is to scale this methodology from the laboratory level to the industrial scale.

For the AI-based analysis of the magnetic field mappings, innovative deep learning methods are employed to identify characteristic features, referred to as “health features” that exhibit a clear correlation with the SoH of the cells. These features enable the classification of cells based on their aging state, e.g. healthy, degraded, or defective. The primary goal is to detect degraded but still functional cells that are no longer suitable for use in electric vehicles due to insufficient capacity. By developing tailored upcycling strategies and exploring new second-life applications in less demanding areas, the project aims to promote the sustainable and resource-efficient use of battery cells. Additionally, it seeks to accelerate their transfer to industry.

Project partners

- Industrial Dynamics GmbH (Coordinator)

- Sekels GmbH

- Battery Dynamics GmbH

- Nehlsen AG

- Friedrich-Alexander-Universität Erlangen-Nürnberg, Group for Applied Quantum Technologies

- Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

Topics

Organizations

Other news from the department science

These products might interest you

Battery Testing Services by Battery Dynamics

Learn more about the performance and service life of your battery cells in less time

Benefit from modern measurement technology and an experienced team

Batt-TDS by ystral

YSTRAL Batt-TDS mixing and dispersing machine

Boost your battery slurry process

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Spectroscopy

Investigation with spectroscopy gives us unique insights into the composition and structure of materials. From UV-Vis spectroscopy to infrared and Raman spectroscopy to fluorescence and atomic absorption spectroscopy, spectroscopy offers us a wide range of analytical techniques to precisely characterize substances. Immerse yourself in the fascinating world of spectroscopy!

Topic World Spectroscopy

Investigation with spectroscopy gives us unique insights into the composition and structure of materials. From UV-Vis spectroscopy to infrared and Raman spectroscopy to fluorescence and atomic absorption spectroscopy, spectroscopy offers us a wide range of analytical techniques to precisely characterize substances. Immerse yourself in the fascinating world of spectroscopy!

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.