3D printer as a reactor for new materials

Chemist Katharina Ehrmann receives the Dr. Ernst Fehrer Prize

Advertisement

3D printers are nothing unusual any more. Today, almost any geometric shape can be designed on a computer and then transformed into real objects using a 3D printer. But Katharina Ehrmann from the Institute of Applied Synthetic Chemistry at TU Wien goes one step further: she can adapt not only the shape, but also the material and its properties with pinpoint accuracy. Her vision: in future, the 3D printer should no longer just be a shaping device, but a flexible reactor for material chemistry. She has now been awarded the Dr. Ernst Fehrer Prize of TU Wien for her work.

Chemist Katharina Ehrmann is developing new 3D printing processes that enable different material properties. She has now received the Ernst Fehrer Prize from TU Wien for her work.

Technische Universität Wien

Liquids that become solid through light

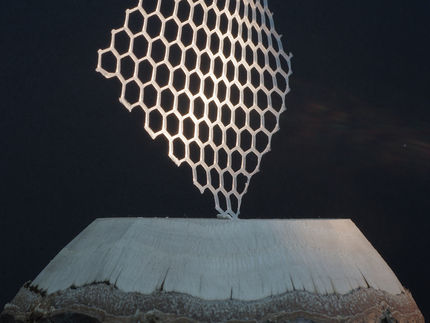

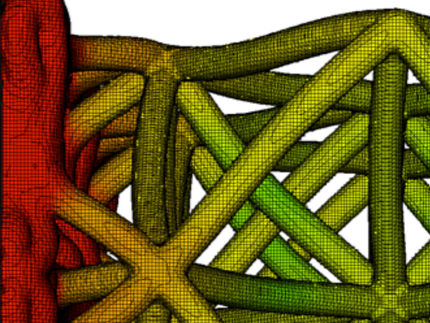

The basic concept of the 3D printers used by Katharina Ehrmann's team is simple: a liquid containing many small molecular building blocks is used. Initially, these building blocks are not connected to each other. But when they are irradiated with light, this changes: where the light is focused and particularly bright, chemical reactions occur, the molecular building blocks are linked together, they form a net-like structure and result in a solid object.

"The crucial question now is: how do these molecular building blocks link up?" says Katharina Ehrmann. "Do they form dense networks with many cross-links, or rather long chains? How are these chains connected to each other? All of this has a major influence on the properties of the material that is created in this way."

For example, materials with many molecular bonds in a small space are often particularly hard and strong, but also rather brittle. A material that consists of long chains that are folded together like an accordion, on the other hand, is easy to stretch and compress. It will therefore be more elastic and malleable.

"Of course, it is ideal if you can produce an object in the 3D printer that has different material properties in different places - just as you need it," says Katharina Ehrmann. There have already been attempts to achieve this by combining different molecular building blocks.

But Ehrmann's approach is different: she can specifically control the way in which the building blocks combine to form large molecules - for example via the brightness or wavelength of the light used, or via the temperature. In this way, completely different materials are created from the same building blocks through different chemical reactions.

"Even small differences in the environmental conditions can lead to the formation of completely different structures at a molecular level," explains Katharina Ehrmann. "There is still huge untapped potential in this area." In the future, it will not only be possible to create any shape using 3D printing, but also to choose from different material properties point by point. The 3D printer will become a materials laboratory.

Katharina Ehrmann

Katharina Ehrmann studied chemistry at the University of Innsbruck and the University of Edinburgh (UK). Her dissertation then took her to the Vienna University of Technology, in the team of Prof. Robert Liska, where she researched the production of biocompatible materials in close collaboration with the Medical University of Vienna. She then went to Queensland University of Technology in Australia as a postdoc. Finally, at the end of 2022, she returned to TU Wien to set up her own research group for additive manufacturing.

On Wednesday, 4 December 2024, Katharina Ehrmann was awarded the Dr. Ernst Fehrer Prize by the Rectorate of TU Wien. This prize was donated by Dr. Rosemarie Fehrer, the widow of the inventor and industrialist Dr. Ernst Fehrer. The prize is awarded annually for special technical research achievements with practical applicability.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.