Swiss start-up Oxyle commissions first complete PFAS destruction system

Key milestone for Oxyle: the company scales its solution to solve PFAS problems on an industrial scale around the world

The widespread contamination of water by PFAS, so-called perpetual chemicals, has become one of the most pressing environmental issues of our time and is making headlines around the world. As industry and regulators search for effective solutions to combat this global crisis, Oxyle has successfully commissioned its first full-scale PFAS destruction system at a contaminated site in Switzerland, providing an affordable, effective and permanent solution.

Oxyle is active in several European markets and has developed a technology that removes PFAS from wastewater and breaks down these chemicals into harmless minerals - with no harmful by-products. Designed specifically for industries such as environmental remediation, chemical production and pharmaceuticals, Oxyle's solution ensures regulatory compliance while significantly reducing operating costs.

The installation in Switzerland addresses groundwater contamination caused by the previous use of PFAS-containing firefighting foam during fire drills. A hydraulic barrier was erected to prevent further spread of the pollutants and the PFAS-contaminated groundwater was treated using conventional methods such as activated carbon. However, these methods proved to be inadequate due to the complexity and cost of managing PFAS-contaminated waste. The limitations of existing technologies have revealed an urgent need for innovative solutions - a role that Oxyle is now fulfilling with this plant.

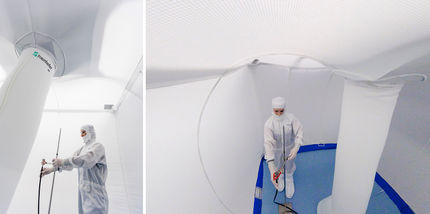

The Oxyle system is tailored to the specific conditions of the site and has already been successfully tested on site prior to full-scale deployment. The system works in three stages: First, PFAS are separated and concentrated by foam fractionation. The concentrated foam is then processed in two reactor modules, where Oxyle's innovative catalytic technology breaks down and mineralizes all short-, medium- and long-chain PFAS. Oxyle continuously monitors the entire process using real-time monitoring technology to ensure maximum performance and operational efficiency. The complete system is housed in a 24-foot container (approx. 7.5 meters) and offers a compact and flexible solution for on-site use.

During operation, the installation treats up to 10 cubic meters of contaminated water per hour - approximately 10 percent of the total water flow at the industrial site - providing an immediate solution to the groundwater contamination there. Over the next six months, the plant will provide important data on long-term performance and scalability for larger industrial applications.

"The first commissioning of our technology in a complete process marks our transformation from promising start-up to innovation leader in PFAS elimination. For the first time, our complete PFAS treatment system is in full-scale operation, operating at less than 1 kWh/m3 - the result of four years of research. However, the practical application of our development is more than a milestone for our company. It is proof that simple, effective and affordable PFAS treatment is not only possible, but already exists," said Dr. Fajer Mushtaq, co-founder and CEO of Oxyle.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.

Topics

Organizations

Other news from the department business & finance

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Something is happening in the chemical industry ...

This is what true pioneering spirit looks like: Plenty of innovative start-ups are bringing fresh ideas, lifeblood and entrepreneurial spirit to change tomorrow's world for the better. Immerse yourself in the world of these young companies and take the opportunity to get in touch with the founders.