Surprise at the grain boundary

For the first time, an international research team has been able to observe how solute elements introduce new grain boundary phases using state-of-the-art microscopy and simulation techniques

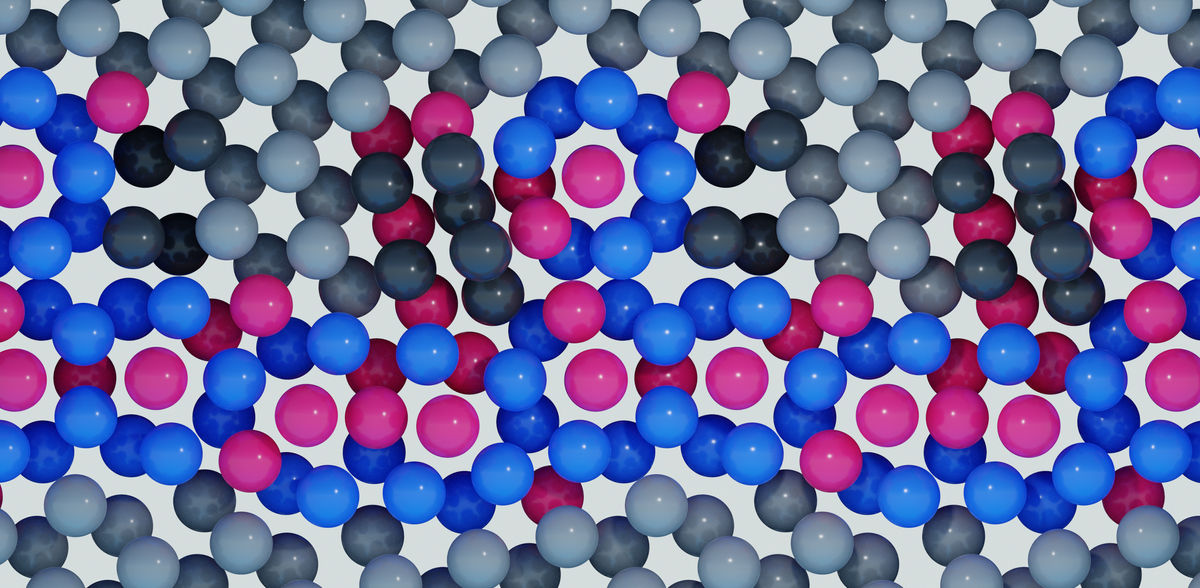

Using state-of-the-art microscopy and simulation techniques, an international research team systematically observed how iron atoms alter the structure of grain boundaries in titanium. They were in for a surprise: “Iron atoms not only segregate to the interface, but they form entirely unexpected cage-like structures,” explains Prof. Dr. Christian Liebscher from the Research Center Future Energy Materials and Systems of the University Alliance Ruhr. The researchers did not expect such a behavior. Their findings have been published in the journal Science on October 25, 2024.

A new type of segregation behavior

Most technological materials have a polycrystalline structure: they are composed of different crystals, where atoms are arranged in a regular lattice. These crystals do not have the same orientation everywhere and the interfaces separating them are known as grain boundaries. “These grain boundaries have an enormous influence on the durability and overall performance of a material,” says Dr. Vivek Devulapalli who has performed the microscopy work of the study. He adds: “But we have very limited understanding what happens when elements segregate to grain boundaries and how they influence the properties of a material.”

The key to success was to observe and model the structures at atomic resolution. The researchers correlated their results from atomic-resolution scanning transmission electron microscopy with advanced computer simulations. A new grain boundary structure prediction algorithm was able to generate the experimentally observed structures and enables to study their structure. “Our simulations show that for different iron contents, we always find the cage structures as the underlying building blocks of different grain boundary phases. As the iron level increases at the grain boundary, more icosahedral units appear and eventually agglomerate,” explains Dr. Enze Chen from Stanford University. An icosahedron is a geometric object with 12 corners or vertices, in this case occupied by atoms, and 20 planes.

“We have identified more than five distinct structures or grain boundary phases of the same boundary, all composed of different arrangements of the same icosahedral cage units,” adds Dr. Timofey Frolov who was leading the computational work of the study.

Quasicrystalline-like grain boundary phases

A closer inspection of the cage structures revealed that the atoms adopt an icosahedral arrangement with iron atoms being located at the center of the icosahedron and titanium atoms occupying its vertices. “The icosahedral cages enable a dense packing of iron atoms and since they can form aperiodic clusters, more than two to three times the amount of iron can be accommodated at the grain boundary,” explains Vivek Devulapalli. “It appears as if iron is trapped inside of quasicrystalline-like grain boundary phases,” adds Chen. “This is attributed to the properties of the icosahedral cages”, says Liebscher, “and we now need to find ways to study how they influence the interface properties and with this the material behavior.”

New pathways for materials design

Understanding and controlling the formation of icosahedral grain boundary phases with different structures and properties can potentially be used to tailor the properties of materials. The researchers now want to systematically investigate how these novel grain boundary states can be used to tune material behavior, adjust a certain material functionality and to make materials more resilient against degradation processes.

Original publication

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.