Inspired by nature: biophysicist develops innovative microplastic filters

"Nature often provides the solution to problems that concern it" - without the example of the giant manta rays, research might not have come up with this idea at all

Advertisement

It's everywhere these days: microplastics. In particular, it is transported through the air and water to the remotest corners of the earth. One of the big questions is: how can we prevent microplastics from entering our waters and thus the environment? One person who is very close to an answer is biophysicist Tim Robertino Baumann. In InCamS@BI, a joint project of HSBI and Bielefeld University, he is developing a new type of filter system for the small particles. After all, it is impossible to imagine our society without plastic.

The actual filter is barely visible to the human eye. The channels themselves are only a few micrometers in diameter. The sample is connected on the left, filtrate and waste come out of the two outlets on the right.

© P. Pollmeier/HSBI, 19.07.2024

"Microfluidics was my least favorite subject in my bachelor's degree, because the laws at work here are completely different from those on a larger scale. But the questions that can be answered with microfluidics are incredibly exciting. That's why I got stuck in and think it's a great field of research!" says Tim Robertino Baumann.

© P. Pollmeier/HSBI, 19.07.2024

It swims majestically through the tropical oceans: the giant manta ray. With wave-like oscillations of its fins, the up to eight-metre-long and seven-metre-wide sea dweller moves along - a bit like a bird with its flights. This species of devil ray can weigh up to two tons and feeds on tiny zooplankton, among other things. The giant simply filters this out of the water during its migration. To make this possible, it has an ingenious system inside it that separates the tiny creatures from the water.

From a biophysical point of view, it is precisely this filter system that is highly exciting for the separation of microplastics from liquids. Tim Robertino Baumann, a doctoral student at Bielefeld University, has been working on transferring this method for almost two years now. The biophysicist is also a technology scout in the transfer project InCamS@BI, the Innovation Campus for Sustainable Solutions of Bielefeld University of Applied Sciences (HSBI) and Bielefeld University. He got the idea for his research from a scientific publication from the USA, but the researchers there have not yet pursued their approach any further. Baumann saw more potential than his American colleagues - and rightly so. In his "Bluewater" project, as he called his master's thesis, he was able to show that the method works. Now he wants to optimize "his" filters.

Microplastics in water: the biggest emitter is clothing

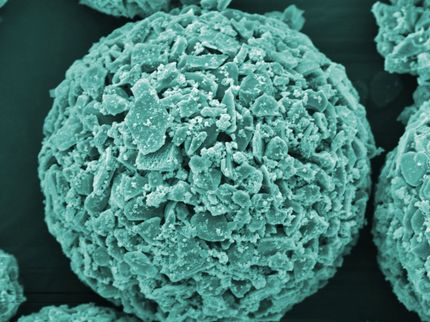

Microplastics are solid particles and fibers that are insoluble in water, consist of synthetic or biological polymers and are often mixed with additives. Their diameter is between one micrometer and five millimeters - anything smaller belongs to the nanoplastic category. Contaminants, such as pathogens or toxins, can even accumulate on the usually very rough surface of the particles. As microplastics slip through sewage treatment plants using conventional filter methods, they are now detected almost everywhere: In agricultural soils, in sewage sludge, in ocean and river waters, in the atmosphere, in snow, in Arctic ice and the deep sea.

Where to start? Tim Robertino Baumann has decided: in the water. If you look at the microplastics in the sea, you can see that 35 percent of the particles come from synthetic clothing, 28 percent from tire abrasion and 24 percent from urban particulate matter. The rest comes from road markings, ship coatings and cosmetics, among other things. The largest emitter is therefore clothing. According to studies, today it consists of 60 percent synthetic fibers. Particularly when textiles are washed, particles and fibers can dissolve and get into the water. According to the Federal Environment Agency, up to 2,000 synthetic fibers from fleece garments are released into the marine environment via watercourses per wash cycle. How to counteract this: Consumers could, for example, spin less, wash textiles less hot and avoid washing fleece fabrics with "hard" garments such as jeans. However, the industry has the greater leverage in this context: it could offer washing machines with microplastic filters - as will be mandatory in France from 2025. However, this requires technology that works very well.

Secondary microplastics are a danger to humans and animals

The InCamS@BI project, in which Baumann is working in addition to his doctorate, is highly interdisciplinary and specializes in optimizing the circular value chain - particularly with regard to plastics. Microplastic filters are a perfect thematic fit, as microplastics are often an end product of plastics - and their recovery is not trivial. If plastic products are not disposed of properly, in the worst case scenario they end up in the environment and degrade into microplastics. The resulting particles are referred to as secondary microplastics. In contrast, primary microplastics are produced in such small quantities and are used in cosmetics or scouring agents, for example.

Microplastics are an acute, omnipresent risk - not only for the environment, but also for animals and humans. According to the World Health Organization (WHO), microplastics have an impact on the digestive, respiratory, cardiovascular and reproductive systems, as well as on the kidneys, liver and thyroid. As it cannot be chemically dissolved in water or biodegraded (except by special bacteria or fungi), microplastics remain in circulation for a very long time and accumulate in and around cells and on cellular components over time. This is particularly critical if toxins and pathogens or harmful additives attached to the plastic are released, leading to inflammation. "Without targeted attempts at recovery, microplastics remain in the water and represent a dead end in the plastic cycle," explains Tim Robertino Baumann. "With targeted basic research, however, this part of the cycle can be closed and transferred from research to industry. This allows us to solve problems directly at the source."

The manta-inspired filter: a system of channels and lamellae

Since making his decision, Tim Baumann has spent many months in the laboratories of the Faculty of Physics at Bielefeld University. The beginning was the most difficult for the 26-year-old: "I tried out so many materials, worked with different bonding methods, got to the bottom of one mistake after another - it was often very frustrating," he recalls. "But then came this one day after nine or ten months of work, when I was sitting in the office with my mentor at the time, Dr. Martina Viefhues, really demotivated because nothing was working. She advised me to keep going and was always optimistic. So I went back to the lab - and suddenly it worked. I was speechless and very happy," says Baumann about his breakthrough.

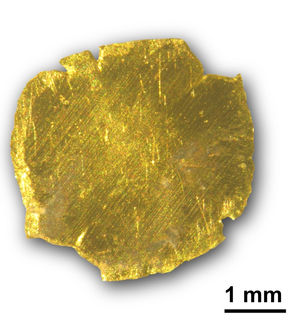

The filters he has produced look somewhat unusual and resemble a channel system: the flow channel is located between a specially produced and shaped silicone and a glass plate, through which the water mixed with microplastics is pumped from one side at a pressure of ten bar - four to five times as much as in a car tire. The particles travel straight through the channel and end up in the "waste" container together with some water. The remaining, pure water finds a different path to the left and right of the center around a kind of lamella. Due to the pressure, it does not flow back again, but into a second container, the "filtrate" container.

Baumann first creates a model on the PC and simulates the water flow. If everything works on the computer, he starts real production. This means that he first creates a mask with which he produces a so-called master wafer using photolithography. This creates a negative relief of the structure, which is then molded with soft silicone, a material that the scientist mixes himself. The silicone is then cut to size, punched and glued to a glass using a special process called plasma oxidation. The actual experiment can then begin: The sample is forced through the filter at high pressure. It consists of water mixed with microplastic particles. Finally, the particle concentration of the filter outputs, i.e. the "waste" and the "filtrate", are compared with each other.

The man-made effects on the environment are not under control

Currently, the method can filter about 81 percent of the particles from the sample. The two containers (clean and contaminated) are always approximately equally full after the tests. 25 milliliters of liquids are "chased" through the filter every minute. In future, Baumann would like to show that the technology also works with a lower water pressure. This is because water in the household usually flows at around 2.5 bar, which is only a quarter of what he is currently using in the experiments. His additional goal is to obtain even more clean water.

He now has support in the laboratory: Ioannis Gkekas is currently writing his bachelor's thesis with Tim Robertino Baumann. Gkekas is changing various parameters in the filter, for example adjusting the shape of the lamellae or varying the spacing. "The research here is cool because there is a lot of potential in the filters. I deliberately chose this work because the pollution of our environment with microplastics is simply socially relevant," says young scientist Gkekas. The scientific research field on which her work is based is known as microfluidics.

Baumann has completed his Master's thesis and is now doing his doctorate on the subject under Prof. Dr. Dario Anselmetti and is working part-time as a technology scout in the InCamS@BI transfer project. Dario Anselmetti explains why the transfer of research is so important: "The exchange of knowledge and the transfer of research results are the basis for the long-term and sustainable further development of our educational society on the basis of fact-based science. It is one of the main tasks of universities and their researchers as part of this society not only to publish their new findings in scientific journals, but also to make them available as directly as possible to companies, public institutions and civil society," says the Vice-Rector for Studies and Teaching at Bielefeld University. Only this would enable the application-oriented implementation of knowledge in innovative products and services and thus contribute to strengthening the economy and creating new future-oriented jobs. "Today, we have long since recognized that our lifestyle, which is often still too resource-intensive, endangers our own livelihood, whereby man himself has become a kind of geological factor. One expression of this is the pollution of our environment with microplastics, which was hardly known ten years ago. Offering innovative, i.e. quick and practicable, solutions here is challenging and scientifically extremely exciting. And this is where Tim Baumann's work comes in," explains the expert. His doctoral student, microfluidics expert Baumann, adds: "As a scientist, I don't want to avoid the challenges, I want to look into them."

The goal is large-scale application in sewage treatment plants, household appliances and processing plants

Baumann is convinced: "In this job, you have to realize that Everything starts with a problem and ends with a new one." If the filter system then works with improved properties in the laboratory, the technology must of course make its way into the application. Baumann's dream is to continue researching the filters until they can actually be used in sewage treatment plants, washing machines or dishwashers, recycling plants or as inlet filters for domestic water pipes. "Maybe I'll even start a company then, who knows?" he muses. His big goal is to develop a good and inexpensive solution for mass use that maximizes throughput and extracts a wide range of particle sizes. If particles in the smallest micrometer range can also be filtered in the future, applications beyond microplastics are also conceivable, for example as drinking water filters against microorganisms.

Baumann is still fascinated by the fact that "nature often provides the solution to problems that affect it" - without the example of the giant manta rays, research might not even have come up with this idea. Because if Baumann's filters can be used at some point and less microplastics end up in the marine environment, not only we humans will benefit - but also the giant manta rays.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.