Old becomes new - how new chemical products are made from used frying oil

Selective one-pot reaction

Advertisement

Every year, 119 million tons of used vegetable oil are produced worldwide, mainly from commercial kitchens and restaurants. Only a small proportion of this is reused, for example in the production of fuels such as biodiesel. At the Leibniz Institute for Catalysis in Rostock (LIKAT), PhD student Fairoosa Poovan has developed a catalyst in Prof. Matthias Beller's research group that uses used cooking oil to synthesize primary amines. These are important precursors for a variety of products in our daily lives, including the manufacture of medicines.

Circular Economy for Carbon

This research supports the global social goals of a CO2 -neutral economy and climate neutrality. Until now, used cooking oil has mainly been processed into biofuels. This means that the atomic carbon in the used cooking oil burns with the diesel and is released into the atmosphere as CO2, with negative consequences for the climate. It would be wiser to keep the carbon when recycling the used cooking oil and put it back into the cycle, where it is also needed. After all, carbon is contained in almost all of our everyday products.

In the face of climate change, societies around the world are learning to do without fossil carbon sources such as coal, oil and gas. Alternatively, chemistry is working with other scientific disciplines to develop concepts and products that follow the guiding principle of the circular economy. This includes obtaining carbon for our economic goods from organic and plastic waste in the future. In this field, the Leibniz Institute for Catalysis is working closely with Otto von Guericke University Magdeburg and the Max Planck Institute of Complex Technical Systems Magdeburg there. One of the joint goals of this cooperation is to find new applications for (bio-based) waste.

Bulk Product Amines

"Our aim is to use used cooking oil as a useful chemical starting material for the production of valuable products," says Fairoosa Poovan. "Amines were an obvious choice." These are derivatives of ammonia (NH3) and are needed on a large scale in organic chemistry. There are dozens of types of amines, and the global market is estimated to be worth over 16 billion US dollars.

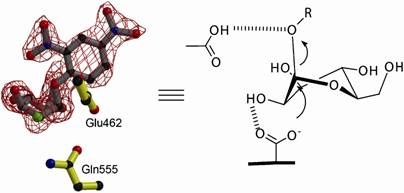

Used cooking oil contains long-chain fatty acids that can be converted into other valuable chemicals. With a suitable catalyst and in the presence of ammonia and hydrogen, they can also be converted into the desired amines. When one of the three hydrogen atoms in ammonia is replaced by another group, chemists refer to these amines as "primary amines" (R-NH2). Fairoosa Poovan developed a cobalt-based catalyst under the supervision of her doctoral supervisor Matthias Beller and Jagadeesh Rajenahally, which can efficiently convert used cooking oil into primary fatty acid amines.

The biggest challenge was to find a selective and cost-efficient way to produce these primary amines from biowaste. Until now, the industry has used the so-called "nitrile route" to produce fatty acid amines. However, this established process has disadvantages. It requires harsh reaction conditions, involves several reaction steps and ultimately results in a product mixture of different amines (primary, secondary and tertiary), which are difficult to separate due to their structural similarity.

Selective One-pot Reaction

The industrial synthesis of fatty amines involves three steps. First: Hydrolysis of vegetable oil to fatty acids. Secondly, amination-dehydration of fatty acids at high temperature (above 250 °C) in the presence of metal oxide catalysts (e.g. aluminium oxide or zinc oxide) to produce fatty nitrates. Finally, thirdly, hydrogenation to produce the desired amines.

"Our aim was to keep the process as simple as possible and to develop a one-pot system in which we combine all substances including catalyst as a solution in one vessel. This significantly improves resource, atom and reaction efficiency," says Fairoosa. Compared to the industrial process, her process works at more moderate temperatures, and due to the high efficiency of the catalyst, the primary amine is produced with "excellent selectivity", as she says. And it is also a cost-efficient way to produce amines, as Fairoosa uses Poovan cobalt, a base metal, as a catalyst.

For the experiment, Fairoosa Poovan used commercially available sunflower oil that was used for cooking. After filtration, she analyzed it in an accredited food quality laboratory, Lufa Northwest. Edible oils are a complex system of different fatty acid components. Most of them have a chain length of 16 or 18 carbon atoms, so the amines produced also differ in the length of the fatty acid chain. According to Fairoosa Poovan, it is important to know the ratio of the different fatty acids in the edible oil used in order to be able to assess the reaction as well as the function and efficiency of the catalyst.

Suitable for the Degradation of Polymers

The process can just as well be used for upcycling plastics, whose recycling problem is very similar, even on a similar scale. Every year, 300 million tons of plastic products leave production facilities worldwide. According to official figures, 53 percent of what ends up in the yellow garbage cans, at least in Germany, is "energetically" recycled, i.e. incinerated.

And that brings us back to the starting point. "There is no way around a circular economy," concludes the chemist. She will defend her dissertation at the University of Rostock next year.

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.