No significant PFAS emissions from waste incineration

Researchers investigate the effectiveness of combustion processes

Advertisement

Perfluorinated and polyfluorinated alkyl compounds, PFAS for short, are found in countless products and therefore also in household waste. Researchers at the Karlsruhe Institute of Technology (KIT), together with international partners, have investigated the contribution of waste incineration to the release of these compounds. Their experiments in the BRENDA incineration plant at KIT showed that incineration at the temperatures and retention times commonly used in European plants almost completely breaks down the fluoropolymers. The study has now been published in the specialist journal Chemosphere.

Coated pans, coffee-to-go cups, pizza boxes, baking paper or medical products: Due to their water-, dirt- and grease-repellent properties, manufacturers use fluoropolymers, a subgroup of per- and polyfluorinated alkyl compounds (PFAS), in a great many consumer products. This group of substances comprises more than 10,000 compounds with different properties - some of which are harmful to health and are associated with the development of organ damage and cancer, for example. PFAS accumulate in groundwater and soil and cause problems for the environment and public health in many places.

Researchers investigate the effectiveness of combustion processes

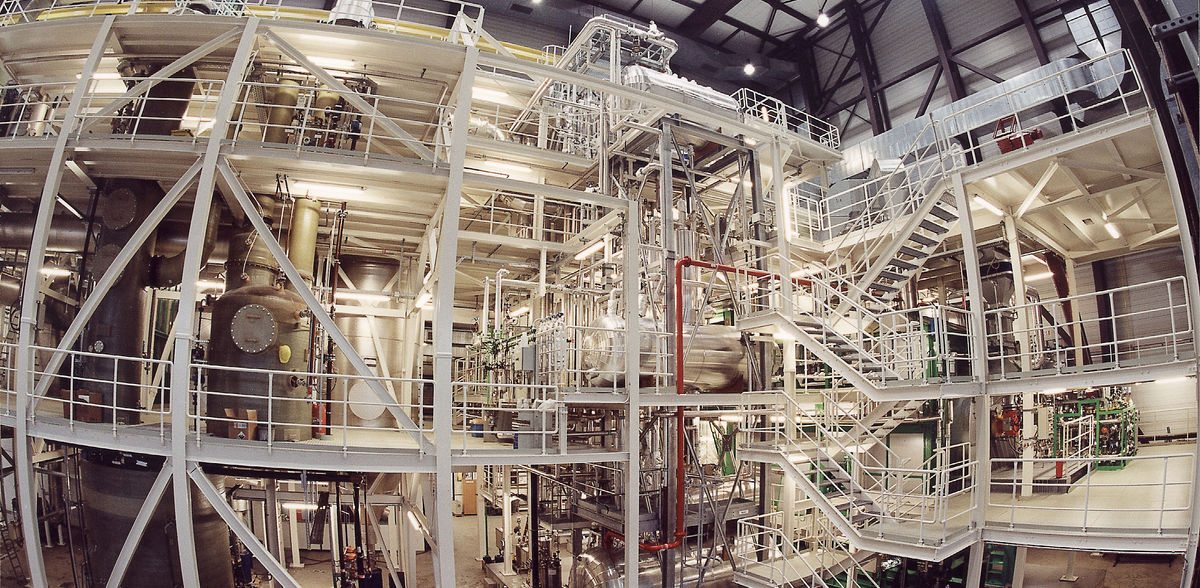

A research team led by Dr. Hans-Joachim Gehrmann from the Institute of Technical Chemistry (ITC) at KIT has now investigated whether and to what extent the compounds are also released into the environment via waste incineration. In cooperation with the Indian company Gujarat Fluorchemicals, a manufacturer of fluoropolymers, the scientists carried out tests on the BRENDA power plant pilot combustion chamber (combustion chamber with steam boiler) at KIT. Fluoropolymers were burned and the PFAS concentrations in the wash water, ash and exhaust gas were subsequently determined. The tests were intended to clarify at which combustion temperatures and conditions the most complete destruction of PFAS can be achieved.

Representative mixture of fluoropolymers

The researchers tested two different temperature conditions: 860 degrees Celsius, corresponding to the European standards for household waste incineration, and 1,095 degrees Celsius, as in the incineration of hazardous waste. In both cases, the minimum residence time for the exhaust gases in the combustion chamber was two seconds. "We were able to show that under combustion conditions of 860 degrees Celsius and a two-second dwell time, a fluorine-related degradation rate of more than 99.99 percent can be achieved. This means that almost complete mineralization of the fluoropolymers was achieved under conditions similar to those in household waste incineration," reports Gehrmann. "Incineration at 1 095 degrees Celsius did not significantly increase the degree of degradation. This suggests that a higher temperature has no significant influence on the mineralization of the fluoropolymers."

For the experiments in the combustion chamber, the team selected a representative mixture of fluoropolymers covering 80 percent of the fluoropolymers used commercially worldwide, including polytetrafluoroethylene (PTFE), polyvinylidene fluoride (PVDF), perfluoroalkoxy polymers (PFA) and fluoro rubber (FKM).

Samples were taken at several points in the combustion process: at the exit of the post-combustion chamber, after the boiler and in the flue gas at the chimney. The team also analyzed samples from the wash water and the ash. Using analytical methods such as coupled gas chromatography-mass spectrometry, PFAS were precisely identified and quantified. "The results are good news for the virtually residue-free disposal of fluoropolymers via household waste incineration in accordance with European standards," says Gehrmann, assessing the research results. "However, PFAS also enter the environment in other ways that still need to be investigated and evaluated."

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.

Original publication

Hans-Joachim Gehrmann, Philip Taylor, Krasimir Aleksandrov, Philipp Bergdolt, Andrei Bologa, David Blye, Priyank Dalal, Priyanga Gunasekar, Sven Herremanns, Deepak Kapoor, Meg Michell, Vanessa Nuredin, Michael Schlipf, Dieter Stapf; "Mineralization of fluoropolymers from combustion in a pilot plant under representative european municipal and hazardous waste combustor conditions"; Chemosphere, Volume 365