Cobalt-copper tandem successfully converts carbon dioxide to ethanol

Sustainability in the focus of chemical research

Advertisement

The continuing release of carbon dioxide into the atmosphere is a major contributor to global warming and climate change with increased extreme weather events. Scientists at Johannes Gutenberg University Mainz (JGU) have now presented a method for effectively converting carbon dioxide into ethanol, which is then available as a sustainable raw material for chemical applications. "We can remove the greenhouse gas CO₂ from the environment and reintroduce it into a sustainable carbon cycle," explained Professor Carsten Streb from the Department of Chemistry at JGU. His working group has shown how carbon dioxide can be electrocatalytically converted into ethanol. If green electricity were used, the process would also be sustainable and food crops that are currently used to produce ethanol for fuels would be available for food again. According to Carsten Streb, the conversion, which has so far been carried out on a laboratory scale, could also be realized on a larger scale. The research results have now been published in the journal ACS Catalysis.

Ideal tandem causes selective electrocatalytic conversion

The electrochemical conversion of CO₂ into multi-carbon products such as ethanol would be an ideal way to obtain fuels with high energy density and valuable chemical raw materials, while at the same time using CO₂ as a starting material and thus removing it from the atmosphere to a certain extent. "To do this, we need suitable catalysts that accomplish this conversion with high selectivity so that we obtain a high yield of the desired product, in our case ethanol," says Carsten Streb.

To this end, his research group has designed a special electrode on which the chemical reactions take place. It is coated with a black powder containing cobalt and copper in precisely dosed quantities. The two metals also have to sit on the electrode at very specific distances. "The initial challenge is to get carbon dioxide to react. There are very strong bonds between the atoms of the molecule, but cobalt can break these bonds," says Streb. This initially produces carbon monoxide - not an ideal raw material for the chemical industry. Therefore, in a second step, copper is used to carry out the reaction to ethanol. "However, this only works if cobalt and copper are close to each other on the electrode," the chemist comments on the actual trick that led to the success.

Top selectivity values are to be increased even further

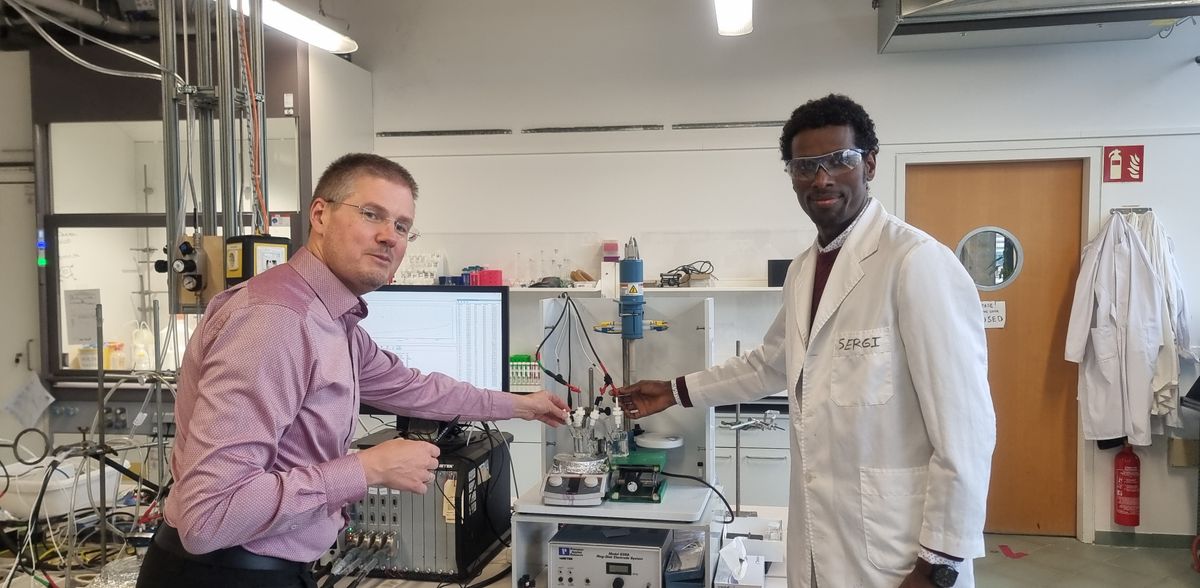

The selectivity of the process is 80 percent, i.e. 80 percent of the starting material is converted into ethanol - the best result achieved in research to date. Dr. Soressa Abera Chala played a key role in optimizing the results. He is the first author of the publication and came to Mainz from Ethiopia on a Humboldt Research Fellowship as a postdoc. Two co-authors, Dr. Rongji Liu and Dr. Ekemena Oseghe, are also working in Streb's field as fellows of the Alexander von Humboldt Foundation. The group is currently working on further increasing the yield to 90 to 95 percent. A catalyst that even achieves 100 percent selectivity would be desirable, so that in the end no other substances are present, only ethanol.

Cooperation within the "CataLight" Collaborative Research Center/Transregio

This also depends on the process control, but especially on the loading of the electrode with cobalt and copper. "You have to be able to see the individual atoms. This is only possible with a special electron microscope," says Streb. The chemists in Mainz are cooperating with the University of Ulm as part of the Collaborative Research Center/Transregio 234 "CataLight". Ultimately, the catalyst should not only be effective, but also function well for as long as possible. The stability of the system, as the research has shown, is excellent and shows no loss of performance even after several months.

Finally, there is another aspect that distinguishes the cobalt-copper tandem and is a key factor in the choice of metals: They are abundant on earth. The entire process could also be set up with precious metals such as platinum or palladium, but at a high price that offers no industrial prospects.

Sustainable production of ethanol conserves food resources and provides new energy

"By using globally available raw materials as catalysts, we are following an approach in current research to increasingly focus on non-precious metals," explains Carsten Streb. In future, this process could be used to sustainably produce ethanol from green electricity and carbon dioxide - for example from power plants. Large quantities of ethanol are currently produced from sugar cane or maize in Brazil, for example, which means that these food crops are no longer available to the population. The process presented here would therefore open up a new and sustainable way of producing ethanol, which could be stored and used for decentralized power generation if required.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.

Original publication

Soressa Abera Chala, Rongji Liu, Ekemena O. Oseghe, Simon T. Clausing, Christopher Kampf, Joachim Bansmann, Adam H. Clark, Yazhou Zhou, Ingo Lieberwirth, Johannes Biskupek, Ute Kaiser, Carsten Streb; "Selective Electroreduction of CO2 to Ethanol via Cobalt–Copper Tandem Catalysts"; ACS Catalysis, 2024-10-5