New method in the fight against forever chemicals

Researchers are for the first time using a technology known as “piezocatalysis”

Researchers at ETH Zurich have developed a new way to break down a dangerous subgroup of PFAS known as PFOS. With the help of nanoparticles and ultrasound, piezocatalysis could offer an effective alternative to existing processes in the future.

What do firefighting foam, non-stick cookware, water-repellent textiles and pesticides all have in common? They all contain per- and polyfluoroalkyl substances, or PFAS – human-made chemicals that don’t break down naturally. It’s no wonder, then, that PFAS are now contaminating soil and water and can also be detected in the bodies of humans and animals. The dangers are well known: these forever chemicals can damage the liver, trigger hormonal disorders and cause cancer, to mention just a few of their effects.

Researchers in the group under Salvador Pané i Vidal, Professor at ETH Zurich’s Institute of Robotics and Intelligent Systems, have developed a new method to break down a subgroup of PFAS called perfluorooctane sulfonates, or PFOS. Due to their toxicity, PFOS are now severely restricted or even banned. “The main problem is that the molecules consist of long carbon chains surrounded by fluorine atoms. This carbon-fluorine bond is so strong that you need a lot of energy to break it,” says Andrea Veciana, a doctoral student of Pané i Vidal’s.

Breaking down molecules with ultrasound and nanoparticles

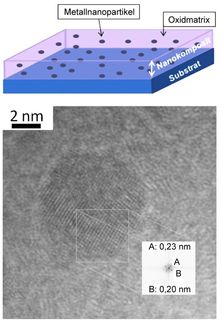

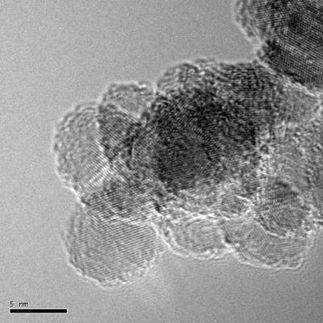

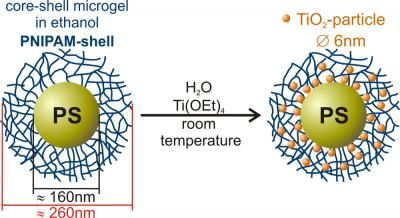

To break up the PFOS molecules and thus degrade them in water, the researchers used piezocatalysis for the first time. “Piezo” refers to piezoelectricity, an electrical charge that is generated during mechanical deformation, and “catalysis” means accelerating a chemical reaction with suitable substances. “We’ve developed nanomaterials that are piezoelectric. To the naked eye, this material looks a bit like sand,” Veciana says. In the ultrasonic bath, these particles become electrically charged and act as a catalyst. Pané i Vidal adds: “It’s this electrical charge that sets the whole chain of reaction in motion and breaks down the PFOS molecules piece by piece. That’s why the nanoparticles are called piezoelectric.”

To measure the PFOS concentration in their samples, the researchers worked with Samy Boulos, analytical specialist from the Laboratory of Food Biochemistry. Using a mass spectrometer, the researchers were able to prove that 90.5 percent of the PFOS molecules were degraded. “However, we should point out that we were working with a very high concentration of 4 milligrams per litre,” Veciana says. “In the natural world, such as in lakes and rivers, the PFOS concentration is less than 1 microgram per litre. And the lower the concentration, the longer it takes for the PFOS to degrade.” Some of the technologies currently in development first concentrate the water and then destroy the PFOS. This would also be a key step in the piezocatalysis, one that would have to be implemented in a specific application such as a chemical industry effluent.

Better than previous methods

The potential of the new method becomes clear when considering the existing options for degrading PFAS. “One method is thermal decomposition, but that requires a temperature of over 1,000 degrees Celsius, which makes it highly energy intensive,” Veciana says. PFAS can also be degraded by photocatalysis. This process is similar to piezocatalysis but uses light for activation of the catalyst instead of mechanical energy. The main problem with this method is that in practice, the objective is to treat wastewater, and since wastewater is cloudy, there is a low light penetration. Veciana mentions a third method: “There’s also absorption, where you use a kind of sponge to soak up the pollutants from the water. But this merely shifts the problem from one place to another; now you need a solution for the PFAS-permeated sponge.”

The disadvantages of the existing methods were one of the reasons the ETH researchers went looking for a new way to break down PFAS. Piezocatalysis has the advantage of being able to work with different sources of mechanical energy. “If water has to be purified in wastewater treatment plants and there’s already turbulence in the water, that energy could perhaps be harnessed to break down the PFAS in it,” Veciana says.

Combating PFAS together

Unfortunately, what the researchers have achieved in the laboratory with water samples of 50 millilitres hasn’t yet been transferred into practice. “The scalability of our method is one of the biggest challenges,” Pané i Vidal says. “However, we’ve succeeded in showing that piezocatalysis works as a method for degrading PFOS and has advantages over previous methods.” Furthermore, their method can not only be used on PFOS, but on any other PFAS and micropollutant.

In general, methods for degrading PFAS should be used before the chemicals get into the environment, i.e. in industrial wastewater treatment plants, or on collected agricultural water for reuse. “Companies should take all possible measures to ensure that the water they release into the environment is as clean as possible,” Pané i Vidal says. Veciana adds: “PFAS are a global problem that should be tackled first and foremost through policy change and more transparency.” There’s already a lot of media coverage about a PFAS ban and stricter regulations to force the industry to be more transparent about the use of these chemicals. Veciana says: “Nevertheless, it’s also important to continue to innovate through research in order to reduce and remediate the existing exposure to PFAS as much as possible.”

Original publication

Andrea Veciana, Sarah Steiner, Qiao Tang, Vitaly Pustovalov, Joaquin Llacer‐Wintle, Jiang Wu, Xiang‐Zhong Chen, Trust Manyiwa, Venecio U. Ultra, Beltzane Garcia‐Cirera, Josep Puigmartí‐Luis, Carlos Franco, David J. Janssen, Laura Nyström, Samy Boulos, Salvador Pané; "Breaking the Perfluorooctane Sulfonate Chain: Piezocatalytic Decomposition of PFOS Using BaTiO3 Nanoparticles"; Small Science, 2024-8-28