Exquisite fragrance from the test tube

A simple synthesis pathway for ambrox, which is found in many perfumes

Advertisement

The fragrance ambrox, which is contained in many perfumes, can be produced more easily in future. A team from the Max Planck Institute for Coal Research and the chemical company BASF has now presented an efficient way of synthesizing the substance. Unlike the chemical process commonly used today, the new method does not require the ingredient of a specific sage species.

People have been using ambrox as a fragrance since ancient times. Today, more than 30 tons of it are produced every year. For a long time, the substance was obtained from ambergris, a waxy substance from the digestive tract of sperm whales. Today, it is produced from sclareol, an ingredient of clary sage, which grows from the Mediterranean to Central Asia. However, this production process for Ambrox requires several reaction steps. In addition, the availability of clary sage varies. Now a research group led by Benjamin List, Director at the Max Planck Institute for Coal Research, in cooperation with the chemical company BASF, has succeeded in synthesizing the fragrant molecule in the laboratory in a different way. The researchers have published the reaction pathway, which is based on a so-called polycyclization, in the scientific journal "Nature".

In biology, polycyclizations are reactions in which enzymes convert simple starting materials into complicated molecular structures in just one step. Benjamin List calls this reaction "a provocation from nature for us chemists", as nature with its large enzymes has an advantage over science. However, the Mülheim team was not deterred by this - on the contrary: "We were inspired by nature in our project," explains Mathias Turberg, who investigated the Ambrox synthesis as part of his doctoral thesis. "We also wanted to develop a method to synthesize complex molecules from rather simple starting materials."

Good prerequisites for industrial application

In the new synthesis method, the Mülheim researchers are starting with nerolidol, which is found in many plants such as ginger and jasmine. The trick here is the interaction between the catalyst and the solvent: while the catalyst initiates the conversion into the product, the solvent stabilizes reactive intermediates. It also acts as a turbo for the catalyst and thus accelerates the reaction even further - and considerably: while the conventional biocatalytic reaction takes three to four days, the new method delivers the product overnight.

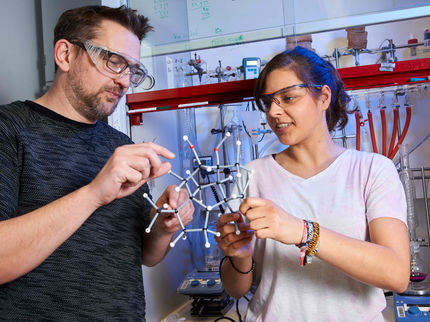

"We have managed to run our reaction under relatively mild conditions - and in a single step," explains Na Luo, who developed the catalyst for the new synthesis as a postdoctoral researcher at the Max Planck Institute for Coal Research. However, of the many possible variants that can be produced in the process, ambrox, which is relevant for the perfume industry, is formed very selectively. Another advantage of the new synthesis route is that it can be easily implemented on an industrially relevant scale. And both the catalyst and the solvent can be recovered and reused for further reactions. Both aspects are important for potential industrial applications.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.