A new idea: conical instead of cylindrical

TU engineers are researching new geometries for gas foil bearings, which are required in air compressors for the operation of fuel cells

Advertisement

The fuel cell is a building block in the transformation of the energy sector - away from fossil fuels such as oil, natural gas and coal and towards renewable energies. In it, the chemical reaction of hydrogen with oxygen produces electrical energy and heat. Gas foil storage systems are essential for this to work. As the name suggests, the lubricant in gas foil bearings is not oil, but air. Why? For the chemical reaction in the fuel cell, oxygen from the ambient air is pumped into the fuel cell under high pressure using a compressor. And where there are rotating components, bearings are needed. If oil were used as a lubricant, it would be impossible to prevent very fine oil particles from contaminating the oxygen when it is pressed into the fuel cell. These impurities can lead to a loss of efficiency and malfunction of the fuel cell. Contamination of the oxygen must therefore be avoided at all costs.

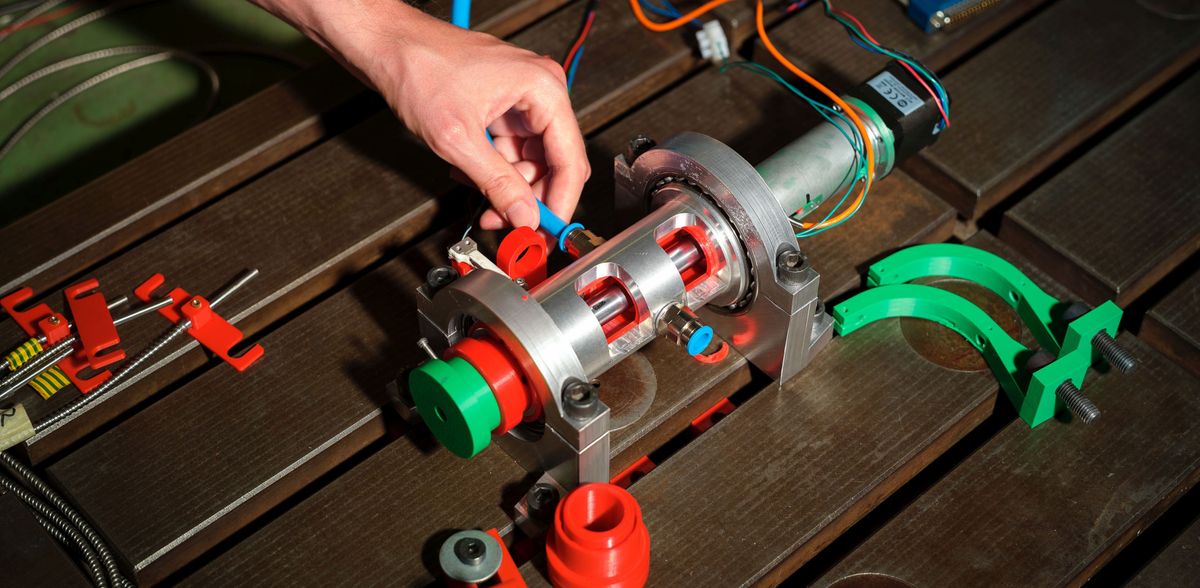

Components of the conical gas foil bearing: aluminum ring with a conical bore (left), corrugated buffer foil that dampens the system (middle), cover foil (middle) and conical shaft (right)

Kevin Fuchs

Goal: more cost-effective and sustainable production

The cylindrical shaft in the compressor is supported radially and axially on both sides in order to counteract the forces that cause the system to vibrate. This requires a total of four bearings. "However, this quadruple bearing of the shaft leads to considerable effort during production and assembly and makes the bearing system highly complex," says Prof. Dr. Robert Liebich, Head of the Design and Product Reliability department. Marian Sarrazin, a research assistant at the department, therefore considered whether this complex bearing could be "slimmed down" with the aim of making production and assembly more efficient, i.e. saving material and minimizing the amount of work involved. In short, to produce the gas foil bearings more cost-effectively and sustainably. His idea: change the geometry of the shaft - not cylindrical, but conical. The conical geometry of the shaft and gas foil bearing would only require two bearings.

Foils dampen the vibrations

Marian Sarrazin's idea of conical gas foil bearings is a novelty. Conical gas foil bearings are therefore not available on the market. In order to find out whether they actually work, Marian Sarrazin builds them himself in the department's workshop and tests them on various test benches. Only a few departments in the world have the necessary production facilities. His conical gas foil bearing consists of an aluminum ring with a conical bore in it. This is lined with a so-called bump foil or buffer foil. This is corrugated and is responsible for damping the system. A so-called top or cover foil lies on top of this. The wafer-thin foils are made of a corrosion-resistant nickel-based alloy and are suitable for applications in the high-temperature range. Marian Sarrazin buys the foils. He shapes them into a conical form himself.

Searching for the optimum speed to form the air film

"Gas foil bearings usually reach speeds of over 150,000 revolutions per minute. These enormous speeds are difficult to achieve with oil or conventional roller bearings. Bearings that use air as a lubricant tend to vibrate strongly at high speeds. The metal foils in a gas foil bearing provide additional damping to control these vibrations," explains Prof. Dr.-Ing.

Marian Sarrazin is now researching the vibration behavior of the shaft in such a conical gas foil bearing on the department's test benches. "Among other things, I have to find out what the optimum speed of the shaft is so that the supporting air film forms in the conical bearing, which is supposed to replace fossil oils as a lubricant. If the speed is too low, no air film will form. If it is too high, vibrations occur that damage or destroy the system," explains Marian Sarrazin.

Maintaining workshops and test benches is essential for research

He uses both numerical simulation methods and experiments to verify the simulations. "One aim of this research project is to create simulations and thus enable reliable predictions that increasingly replace the cost-intensive construction of prototypes in our case of conical gas foil bearings. The industry shies away from these costs. But a simulation can only ever be as good as the values validated by practical experiments. At my department, we don't just simulate, we also check the numerical model using data that we have obtained in experimental studies. That is why it is essential to maintain the workshops and test benches at the TU Berlin. They are an important basis for our sought-after expertise in research and industry," says Prof. Dr.-Ing.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.