Major breakthrough: New additive process can make better — and greener — high-value chemicals

“Our research opens up fascinating possibilities for the future of pharmaceutical and agrochemical development”

Researchers at the Center for Advanced Bioenergy and Bioproducts Innovation (CABBI) have achieved a significant breakthrough that could lead to better — and greener — agricultural chemicals and everyday products.

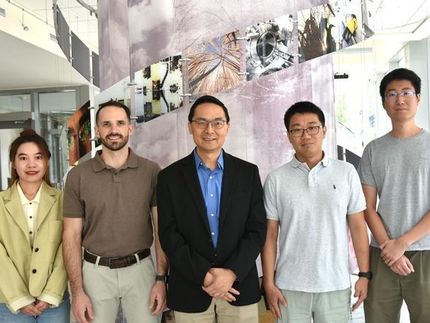

A research team from the Center for Advanced Bioenergy and Bioproducts Innovation (CABBI) used a photoenzymatic process to precisely mix fluorine, an important additive, into widely used chemicals called olefins. This groundbreaking method offers an efficient and eco-friendly strategy for creating high-value chemicals with potential applications in agrochemicals, pharmaceuticals, renewable fuels, and more. From left are Yujie Yuan, Zhengyi Zhang, CABBI Conversion Theme Leader Huimin Zhao (seated), Wesley Harrison, and lead author Maolin Li in their lab at the Carl R. Woese Institute for Genomic Biology at the University of Illinois Urbana-Champaign.

Center for Advanced Bioenergy and Bioproducts Innovation (CABBI)

Using a process that combines natural enzymes and light, the team from the University of Illinois Urbana-Champaign developed an eco-friendly way to precisely mix fluorine, an important additive, into chemicals called olefins — hydrocarbons used in a vast array of products, from detergents to fuels to medicines. This groundbreaking method offers an efficient new strategy for creating high-value chemicals with potential applications in agrochemicals, pharmaceuticals, renewable fuels, and more.

The study, published in Science, was led by CABBI Conversion Theme Leader Huimin Zhao, Professor of Chemical and Biomolecular Engineering (ChBE), Biosystems Design Theme Leader at the Carl R. Woese Institute for Genomic Biology (IGB), and Director of the NSF Molecule Maker Lab Institute at Illinois; and lead author Maolin Li, a Postdoctoral Research Associate with CABBI, ChBE, and IGB.

As an additive, fluorine can make agrochemicals and medicines work better and last longer. Its small size, electronic properties, and ability to dissolve easily in fats and oils all have a profound impact on the function of organic molecules, augmenting their absorption, metabolic stability, and protein interactions. However, adding fluorine is tricky and usually requires complex chemical processes that are not always friendly to the environment.

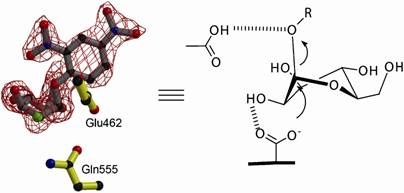

The scientists in this study used a “photoenzyme” — a repurposed enzyme that works under light – to help bring fluorine into these chemicals. By using light and photoenzymes, they were able to precisely attach fluorine to olefins, controlling exactly where and how it is added. Because this method is not only environmentally friendly but very specific, it allows for more efficient creation of useful new compounds that were difficult to make before.

This approach fills a large gap in molecular chemistry, as previous methods to add fluorine were limited and inefficient. It also opens up new possibilities for creating better medicines and agricultural products, as fluorinated compounds are often more effective, stable, and longer-lasting than their non-fluorinated counterparts. That means fertilizers and herbicides could be more effective in protecting crops, and medicines could be more potent or have fewer side effects.

“This breakthrough represents a significant shift in how we approach the synthesis of fluorinated compounds, crucial in numerous applications from medicine to agriculture,” Zhao said. “By harnessing the power of light-activated enzymes, we’ve developed a method that improves the efficiency of these syntheses and aligns with environmental sustainability. This work could pave the way for new, greener technologies in chemical production, which is a win not just for science, but for society at large.”

The research advances CABBI’s bioenergy mission by pioneering innovative methods in biocatalysis that can enhance the production of bio-based chemicals — those derived from renewable resources such as plants or microorganisms rather than petroleum. The development of more efficient and environmentally friendly biochemical processes aligns with CABBI’s focus on creating sustainable bioenergy solutions that minimize environmental impact and reduce reliance on fossil fuels.

It also contributes to the broader U.S. Department of Energy (DOE) mission of driving advances in bioenergy and bioproducts. The methods developed in this study can lead to more sustainable industrial processes that are less energy-intensive and reduce chemical waste and pollution, supporting DOE’s goals of fostering clean energy technologies. The ability to efficiently create high-value fluorinated compounds could lead to enhancements in various fields, including renewable energy sources and bioproducts that support economic growth and environmental sustainability.

“Our research opens up fascinating possibilities for the future of pharmaceutical and agrochemical development,” Li said. “By integrating fluorine into organic molecules through a photoenzymatic process, we are not only enhancing the beneficial properties of these compounds but also doing so in a manner that’s more environmentally responsible. It’s thrilling to think about the potential applications of our work in creating more effective and sustainable products for everyday use.”

Original publication

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.