Liquid method: pure graphene production

Research could yield novel composites, touch-screen displays

In a development that could lead to novel carbon composites and touch-screen displays, researchers from rice University and the Technion-Israel Institute of Technology unveiled a new method for producing bulk quantities of one-atom-thick sheets of carbon called graphene.

When stacked together, graphene sheets make graphite, which has been commonly used as pencil lead for hundreds of years. It wasn't until 2004 that stand-alone sheets of graphene were first characterized with modern nanotechnological instruments. Since then, graphene has come under intense scrutiny from materials scientists, in part because it is both ultrastrong and highly conductive.

"There are high-throughput methods for making graphene oxide, which is not as conductive as graphene, and there are low-throughput methods for making pure graphene," said lead co-author Matteo Pasquali, professor of chemical and biomolecular engineering and chemistry at Rice. "Our method yields very pure material, and it is based on bulk fluid-processing techniques that have long been used by the chemical industry."

Pasquali said the research team found it could dissolve graphite in chlorosulphonic acid, a common industrial solvent. The researchers had to devise new methods to measure the aggregation of the dissolved graphene flakes, but at the end the team was pleasantly surprised to find that the individual graphene layers in the graphite peeled apart spontaneously. The team was able to dissolve as much as two grams of graphene per liter of acid to produce solutions at least 10 times more concentrated than existing methods.

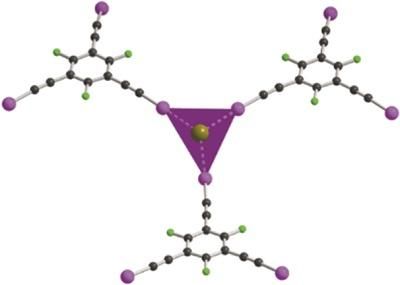

The researchers took advantage of novel cryogenic techniques for electron microscopy that allowed them to directly image the graphene sheets in the chlorosulfonic acid.

"We applied new methods that we had developed to directly image carbon nanotubes in acid," said co-author Yeshayahu "Ishi" Talmon, professor of chemical engineering at the Technion-Israel Institute of Technology. "This was no small feat considering the nature of the acid and the difficulty of specimen preparation and imaging."

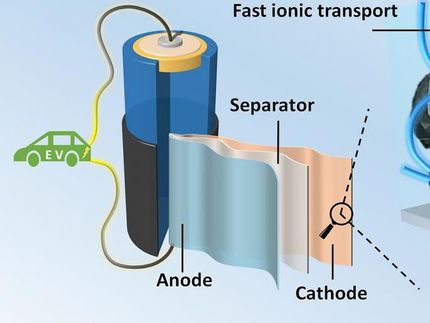

Using the concentrated solutions of dissolved graphene, the scientists made transparent films that were electrically conductive. Such films could be useful in making touch screens that are less expensive than those used in today's smart phones. In addition, the researchers also produced liquid crystals.

"If you can make liquid crystals, you can spin fibers," said study co-author James Tour, Rice's T.T. and W.F. Chao Professor of Chemistry. "In liquid crystals, the individual sheets align themselves into domains, and having some measure of alignment allows you to flow the material through narrow openings to create fibers."

If the method proves useful for making graphene fibers in bulk, it could drive down the cost of the ultrastrong carbon composites used in the aerospace, automotive and construction industries.

Original publication: Nature Nanotechnology 2010

Most read news

Topics

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

'Microfluidic palette' may paint clearer picture of biological processes

Krabbe_disease

Nanocellulose materials by design - Theoretically, nanocellulose could be the next hot supermaterial

Lenzing and Acordis - US Joint Venture

Mitsui Chemicals to License PP Process to Thai Polypropylene

Tripos Completes Acquisition of Optive Research, a Molecular Discovery Software Company

Accelrys Announces Pfizer Inc. as the First Member of the Enterprise Cheminformatics Consortium - Consortium to Drive the Evolution of Enterprise Cheminformatics Systems Using Open and Flexible Service-Oriented Architecture

The buzz on an amazing new mosquito repellent: Will it fly?

Orion sues generic drug companies in the U.S. to enforce patents for entacapone