CO2 as a sustainable raw material

TU Berlin presents tandem electrolyzer for a circular economy with carbon dioxide

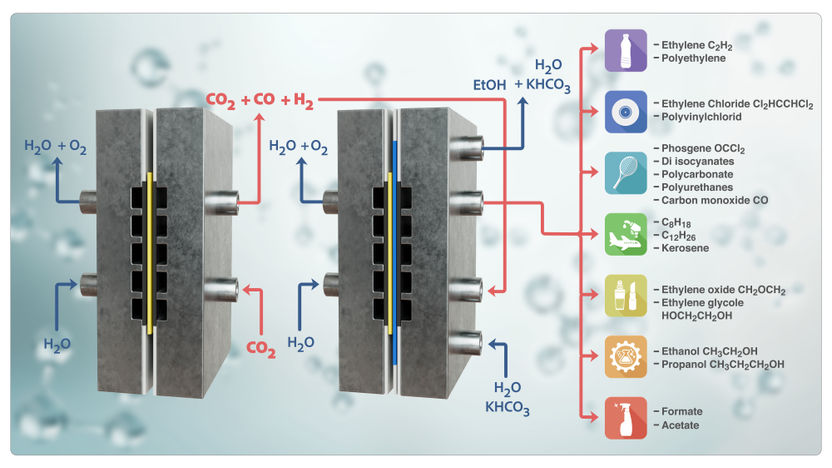

Scientists at TU Berlin have presented a combination of two electrolysis cells that can convert carbon dioxide together with water directly into basic chemicals for the chemical industry with the help of electricity. In the first electrolysis, carbon monoxide is first produced from carbon dioxide, which then forms hydrocarbons together with water in the second electrolysis cell. In contrast to the expensive metal catalysts usually used, a carbon electrode doped with a few nickel atoms and nitrogen is used here, which only requires a metal content of less than one percent. In addition, the researchers have developed a diagnostic system that monitors the condition of the tandem electrolyser during operation and thus contributes to a longer service life and a better understanding of the chemical processes in the cells.

Reaction diagram of the tandem electrolyzer

© TU Berlin

Extracting carbon dioxide from the air or directly from exhaust gases and converting it into valuable chemicals using electricity from renewable energy sources seems like the ideal way to combat the climate crisis. The key to this is electrolysis. Using water (H2O) and electricity, it can reduce carbon dioxide (CO2) to virtually pure carbon monoxide (CO), while simultaneously producing oxygen (O2). Carbon monoxide and additional water can then react in a second step to form useful hydrocarbons such as ethylene, which consist of longer chains of carbon and hydrogen atoms.

Better yield and energy efficiency with tandem electrolysis cells

"In the case of electrolysis of water andCO2 to CO and some hydrogen as a by-product, the proportion of CO in the total amount of substance converted is much higher than in alternative thermal processes that use green hydrogen andCO2 to produce CO and water at temperatures of around 800 degrees," says Prof. Dr. Peter Strasser, head of the Electrochemical Catalysis, Energy and Materials Sciences department at TU Berlin, describing the advantages of the method. For the second step, the production of basic chemicals for the chemical industry from CO and water, there are several competing processes. "If this step is also carried out electrochemically, this has so far often been done in the same electrolysis cell in which the CO is produced. To ensure that all the necessary processes can take place in sequence, compromises must of course be made with the catalyst and the chemical conditions, which leads to suboptimal results. We therefore use two cells in tandem, one of which supplies CO, which is then converted directly into valuable hydrocarbons in the second cell." Depending on the catalyst formulation, the second step produces reactive hydrocarbons such as ethylene, propylene and some acetylene, as well as liquid compounds such as methanol, ethanol and propanol or acetate.

Less metal required thanks to new carbon electrode

Peter Strasser and his team are also breaking new ground with the electrode that convertsCO2 into CO. Normally, silver is used here as a material to catalyze the chemical reactions. "This is not only rare and expensive, but can also corrode and form films on the surface that impair its function as a catalyst," says PhD student Sven Brückner, first author of the publication. "We therefore use a carbon electrode in which atoms of the elements nickel and nitrogen have been incorporated as catalysts in some places." Because the carbon used is porous and therefore has a large surface area, and the atoms incorporated using a special process are only located on the surface, the proportion of nickel required can be kept extremely low - it is less than one percent of the total weight.

"Because such electrodes have only been around for a few years and always have to be optimized for the respective application, their service life and the maximum achievable catalyst performance are still the subject of research," reports Brückner. However, because the electrode is produced at higher temperatures than the operating temperature and other chemical conditions during operation are milder than during production, he is optimistic that successes can soon be achieved here. The team hopes to significantly extend the current stability over several hundred hours.

Diagnostic tool for optimized research and longer service life

Other operating parameters of the tandem cell also still need to be optimized. "The ratio of carbon monoxide and the by-product hydrogen in the first cell depends on the pH value of the electrolyte," explains Sven Brückner. Because the process is intended to deliver the largest possible amount of CO as a building block for hydrocarbons,CO2 electrolysis is carried out under alkaline conditions, which favor the formation of carbon monoxide. "However, this leads to the OH ions in the alkaline electrolyte reacting with theCO2 to form carbonate, which can be deposited and thus damage the cell." According to Brückner, it is therefore important to find the optimum compromise between the various electrolysis parameters.

In order to find this, the research team has developed a special coefficient that makes it easier to determine the optimum process conditions. It contains the production rates of CO and hydrogen as well as the amount ofCO2 still present at the output of the first cell in a mathematical formula. "We measure the concentrations of these substances in a gas chromatograph. We also determine the concentration of the gas nitrogen, which we add in a defined quantity," says Brückner. With this "calibration", the total flow rate through the cell can be determined. Because all these values can be collected continuously while the cell is in operation, the effects of changes to the operating parameters can be determined immediately. At the same time, the measured values also serve as an early warning system for when the cell is at risk of failure and countermeasures are required.

Sustainable carbon economy withCO2 as a raw material

"The ultimate aim of this research is to establish a circular, sustainable carbon economy," explains Peter Strasser. "A major advantage of our process is that we do not need any additional hydrogen for the direct electrolysis ofCO2 into useful hydrocarbons using electricity and water." This is different with conventional sustainable processes, which either use hydrogen to convertCO2 into CO or to produce hydrocarbons from CO, which requires additional energy to be produced, stored and, if necessary, transported. "Base chemicals that useCO2 from the air instead of petroleum as a carbon source can actually reduce the carbon dioxide content of the atmosphere under certain conditions. Green e-fuels made fromCO2 at least have a balanced carbon footprint after combustion," concludes Strasser.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.