Direct lithium extraction from spent batteries for efficient lithium recycling

This study proposed a simple, efficient, and low-energy chemical leaching strategy

Recently, the research findings of Professor Xie's group (Huazhong University of Science and Technology) were published in Science Bulletin. This study proposed a simple, efficient, and low-energy chemical leaching strategy, utilizing a lithium extraction solution composed of polycyclic aromatic hydrocarbon reagents and ether solvents to directly extract active lithium from retired batteries.

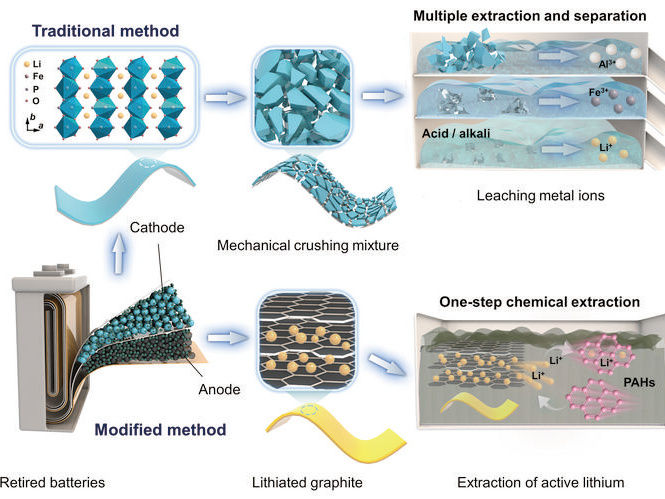

The traditional hydrometallurgical method for recycling metals from spent lithium-ion battery cathode materials involves complex processes such as metal leaching, precipitation, separation, and purification. An improved recycling approach involves directly chemically extracting active lithium from lithium-graphite anodes at room temperature.

©Science China Press

Researchers screened a series of reagents with different redox potentials and solubilities based on the molecular structural characteristics, and studied their binding mechanisms with lithium. Moreover, by systematically analyzing the relationship between the redox potential and extraction efficiency, coupled with theoretical calculation, the optimal reagent was selected. The efficient recovery of active lithium from spent batteries was achieved through the optimization of solvent and process parameters.

Notably, the recovered active lithium can serve as crucial lithium sources. It can be directly employed to react with iron phosphate through spontaneous redox reactions, thereby preparing high-performance lithium iron phosphate materials. Physicochemical characterization and electrochemical performance tests confirmed the superiority of the materials prepared by this strategy. In addition, the recycling of lithium from commercial batteries enabled the large-scale preparation of lithium iron phosphate cathode materials, demonstrating their practical application prospects.

Importantly, lithium extraction solutions operate within a closed-loop system, minimizing the possibility of environmental pollution. In addition, the lithium extraction reagents can be recycled for reuse. Compared with other recycling technologies, this technique has good economic benefits and practical prospects, and it is expected to promote the sustainable development of the lithium-ion batteries.

Original publication

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.