BASF to build new fermentation plant for crop protection products in Ludwigshafen

Strengthening the portfolio of biological and biotechnology-based crop protection products

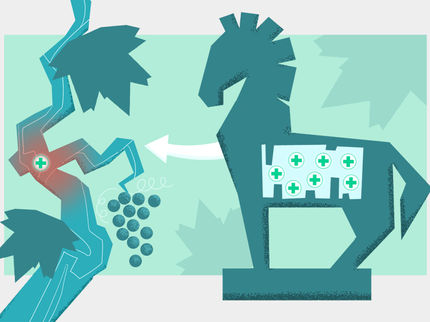

BASF invests a high double-digit million euro amount in a new fermentation plant for biological and biotechnology-based crop protection products at its Ludwigshafen site. The plant will manufacture products that bring value to farmers including biological fungicides and biological seed treatment. BASF also plans to utilize the plant to produce the main building block of Inscalis®, a novel insecticide derived from a fungal strain. Commissioning is planned for the second half of 2025. The plant will employ 30 people in production, logistics, engineering and maintenance.

The plant will use microorganisms to convert renewable raw materials such as glucose into the desired products – a process known as fermentation.

“We see a growing demand for biological crop protection products. This investment is an important step in building an even stronger and more competitive portfolio in this area,” said Marko Grozdanovic, Senior Vice President, Global Strategic Marketing at BASF Agricultural Solutions. “In addition, fermentation is a very flexible technology that will allow us to bring more innovative biotechnology-derived products to the market in the future.”

“For production at our Ludwigshafen site, this development is another step in the transition to innovative manufacturing processes with lower energy intensity based on renewable raw materials,” said Christian Aucoin, Senior Vice President, Global Operations at BASF Agricultural Solutions. “The site offers excellent synergies due to its good infrastructure, the integration into an existing high-performance production organization and the proximity of research units such as White Biotechnology.”

Most read news

Other news from the department manufacturing

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.