C1 proves continuous green methanol production process in record time, confirming predictions from quantum chemistry

Start-up sets a new standard in green methanol production while tripling innovation speed with the predictive power of quantum chemistry

Climate tech start-up C1 just completed its first fully autonomous, fully continuous Methanol production cycle at its “C1 alpha” miniplant in Berlin Adlershof. For the first time worldwide, the company has run a homogeneous methanol catalysis process continuously without operator intervention for a duration of 20 days on end. At mild conditions of 20 bar and 120° Celsius, “C1 alpha” has reached a single pass CO conversion of 95% with a selectivity of 95% – confirming the company’s early predictions from its advanced quantum-chemical simulations.

Team C1 alpha (left to right): Carlo Alberto Genovese, Stephan Ost, Kay Horny and Felix Pohl

Copyright: C1

When compared to traditional methanol production, C1 now achieves a proven single pass efficiency that is about five times higher while temperature and pressure can be reduced by more than 50 percent.

C1 hereby sets a new standard in green methanol production, proving the advantages of the patented C1 catalysis and the predictive power of quantum chemical simulation. The company has reached this important milestone less than one year after commissioning its first chemical reactor, effectively cutting the usual development time for a new catalyst from invention to commercial application from 15 years to 5 years.

Dr.-Ing. Ralph Kraehnert, Chief Engineer at C1: “Going from batch-testing to continuous operations is critical for any industrial process. There is a lot of new chemistry going on around the world that works in a pot. But it only starts to mean anything if you can get that chemistry to run continuously. It requires having all the different unit operations front to back seamlessly integrated and operating in harmony. I am proud of the team for having achieved this in record time.”

Dr. Marek Checinski, inventor and Chief Scientific Officer, comments: “We successfully demonstrated that we can continuously separate our catalyst from the produced methanol and recycle it back with minimal loss of activity. The process operates at mild conditions and exhibits excellent selectivity and performance. No significant side reactions occurred, we observed less than 0.05% water content in the raw product. The chemistry works as predicted in our simulations. This is fantastic news.”

Christian Vollmann, CEO, adds: “We leverage the unprecedented predictive power of our quantum-chemical computer simulations to reduce the risk of running multiple stages of technology development in parallel, instead of sequentially. This way, we cut the development time of a new catalysis from invention to commercial application from 15 years down to 5. This strategy has just been confirmed by real world results from our reactor. It will allow us to substantially reduce production cost of green methanol going forward and puts C1 at the forefront of updating traditional catalysis for the 21st century.”

Most read news

Other news from the department manufacturing

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Something is happening in the chemical industry ...

This is what true pioneering spirit looks like: Plenty of innovative start-ups are bringing fresh ideas, lifeblood and entrepreneurial spirit to change tomorrow's world for the better. Immerse yourself in the world of these young companies and take the opportunity to get in touch with the founders.

Last viewed contents

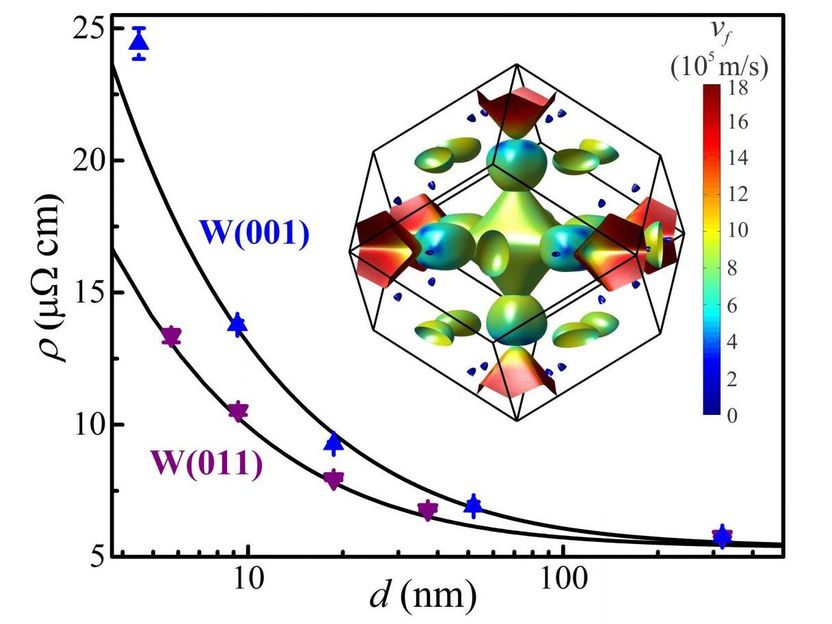

Tungsten offers nano-interconnects a path of least resistance

For the first time, scientists catch water molecules passing the proton baton