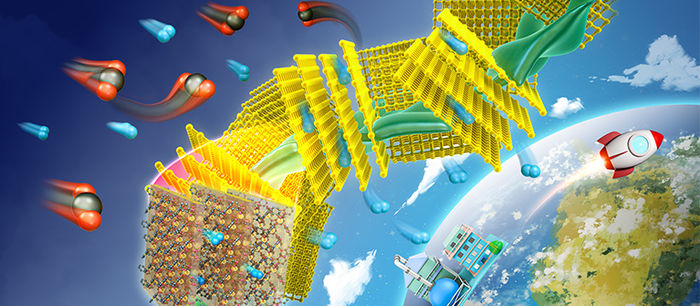

A 3D view into chaos: Researchers visualize temperature-driven turbulence in liquid metal for the first time

Experiments with liquid metals could not only lead to exciting insights into geophysical and astrophysical flow phenomena, such as atmospheric disturbances at the rim of the sun or the flow in the Earth's outer core, but also foster industrial applications, for example the casting of liquid steel. However, as liquid metals are non-transparent, suitable measurement techniques to visualize the flow in the entire volume are still lacking. A team at the Helmholtz-Zentrum Dresden-Rossendorf (HZDR) has now for the first time obtained a detailed three-dimensional image of a turbulent temperature-driven liquid metal flow using a self-developed method. In the Journal of Fluid Mechanics, they report on the challenges they had to overcome on the way to get there.

Ever since researchers have been investigating the properties of turbulent flows in fluids, they use an experiment that initially seems quite simple: the fluid is filled into a container whose base plate is heated and whose lid is cooled at the same time. A team of the Institute of Fluid Dynamics at HZDR is investigating the very details of this process. "If the temperature difference in the fluid exceeds a certain limit, the heat transport is drastically increased," says team leader Dr. Thomas Wondrak. This happens because a so-called convective flow forms, which effectively transports the heat. The liquid at the bottom expands, becomes lighter and rises upwards, while the colder layers at the top sink downwards due to their higher density. "Initially, a regular circulation forms, but at higher temperature differences the flow becomes increasingly turbulent. Visualizing this process correctly in all three dimensions is a challenge," says Wondrak, briefly describing the initial situation of the experiment.

Here, contactless inductive flow tomography (CIFT), a measurement technique developed at HZDR, comes into play: with its help, the researchers are able to visualize a three-dimensional flow in electrically conductive liquids. They use the principle of motion induction: if a static magnetic field is applied, an electric current is generated in the fluid due to the movement of the liquid. These eddy currents cause a change in the original magnetic field, which can be measured outside of the vessel. In this way, the flow structure is reflected in the magnetic field distribution and can be extracted from the measurement data using a suitable mathematical method. Wondrak's team has now used this measurement technique to unveil the temperature-driven flow in a gallium-indium-tin alloy, which melts at around 10 degrees Celsius. The central component of the experiment is a 64-centimeter-high cylinder containing around 50 liters (approximately 350 kilograms) of liquid metal, which is equipped with a sophisticated arrangement of 68 sensors to record the temperature distribution and 42 highly sensitive magnetic field sensors.

Low-interference night-time experiments

In addition to the sophisticated mathematics involved in reconstructing the velocity field from the magnetic data, the main challenge is to measure the very small flow-induced magnetic fields, as these are typically around two to five orders of magnitude smaller than the applied magnetic field. With an excitation field of 1,000 microtesla, the flow-induced magnetic field to be measured is approximately 0.1 microtesla. For comparison: the earth's magnetic field, which is also recorded and subtracted from the measurement values, is around 50 microtesla strong. "The smallest electromagnetic interference, which occurs when electrical devices are switched on, for example, can interfere with the measurement signal and must be filtered out. In order to keep the influence of interference to a minimum, we only carry out experiments at night," says Wondrak, explaining the measurements.

Each of these night-time measurements provides a large amount of experimental flow data that gives researchers a completely new insight into the complicated, constantly changing flow structures. The data obtained experimentally is unique, as numerical simulations for the same flow parameters of comparable duration are not feasible in a reasonable amount of time, even in today's age of high-performance computing.

Wondrak's team uses modern mathematical concepts to recognize spatial structures in the complex velocity fields. For example, the scientists were able to identify recurring patterns of one or more rotating vortices lying on top of each other in the vessel. This brings at least a little order into the turbulent chaos and, among other things, helps to understand better the relationship between flow and heat transport.

The physicists can also transfer the knowledge gained in the laboratory experiment to much larger dimensions in geophysics and astrophysics, such as flow processes in the interior of planets and stars, by applying dimensionless parameters that have their origins in similarity theory.

Outlook: New objectives

Having demonstrated the potential of contactless inductive flow tomography with the current publication, the researchers are now turning their attention to further developing the measurement method. Appending an additional excitation magnetic field and the use of new types of magnetic field sensors promise an increase in measurement accuracy. Wondrak's team is optimistic that this method will soon provide even deeper insights into turbulent liquid metal flows.

Original publication

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.