Revamped plastics recycling chain

Today’s waste, tomorrow’s valuable resource

These days, the majority of consumable and everyday items are made from petroleum-based plastic. In Germany alone, some six million tons of plastic waste are generated every year. Approximately half of this is mechanically recycled into new materials; the rest is used for energy recovery. Incinerating this waste releases CO2, a greenhouse gas. So from a climate and environmental protection point of view, it is important to keep more plastics in the materials cycle. As part of the Waste4Future flagship project, eight Fraunhofer institutes are developing new ideas and processes to significantly improve the mechanical recycling rate for plastic materials.

Many everyday items would be unimaginable without plastics such as polyethylene, polypropylene or polystyrene, all of which are made from fossil-based raw materials. The problem is that the mechanical recycling rate for plastic materials is still too low in Germany. More plastic waste is currently incinerated than is mechanically recycled into new materials. Although incinerating waste takes advantage of its energy potential, valuable materials are lost forever. In a true circular economy, waste would not be incinerated but instead reused and recycled either mechanically or chemically — or avoided in the first place. This not only reduces the demand for fossil-based resources but also environmental pollution from carbon emissions. What’s more, the carbon content in the plastic would be preserved as an important resource for use in the chemical industry. Eight Fraunhofer-Gesellschaft institutes and research units are pooling their expertise together in the Waste4Future flagship project to develop new solutions to this challenge, from raw materials through material flows and process engineering to the end of a product’s life cycle. The Fraunhofer Research Institution for Materials Recycling and Resource Strategies IWKS is coordinating the project.

“Plastics are made from hydrocarbons. At the end of their service life, these are disposed of and are then sorted. Low-quality plastic with too much contamination is incinerated, while high-quality plastic is sorted according to color and sold as recycled material. But recycling these valuable materials according to type is complicated,” says Dr. Gert Homm, head of one of the sub-projects and research scientist at Fraunhofer IWKS in Alzenau. “A lot of packaging is not even considered recyclable by the sorting facilities and ends up in the incineration plant as residual waste. Many of today’s sensors fail to recognize black plastic, and even yogurt cartons with aluminum foil lids end up with the aluminum by mistake and then in residual waste.”

Today’s waste, tomorrow’s valuable resource

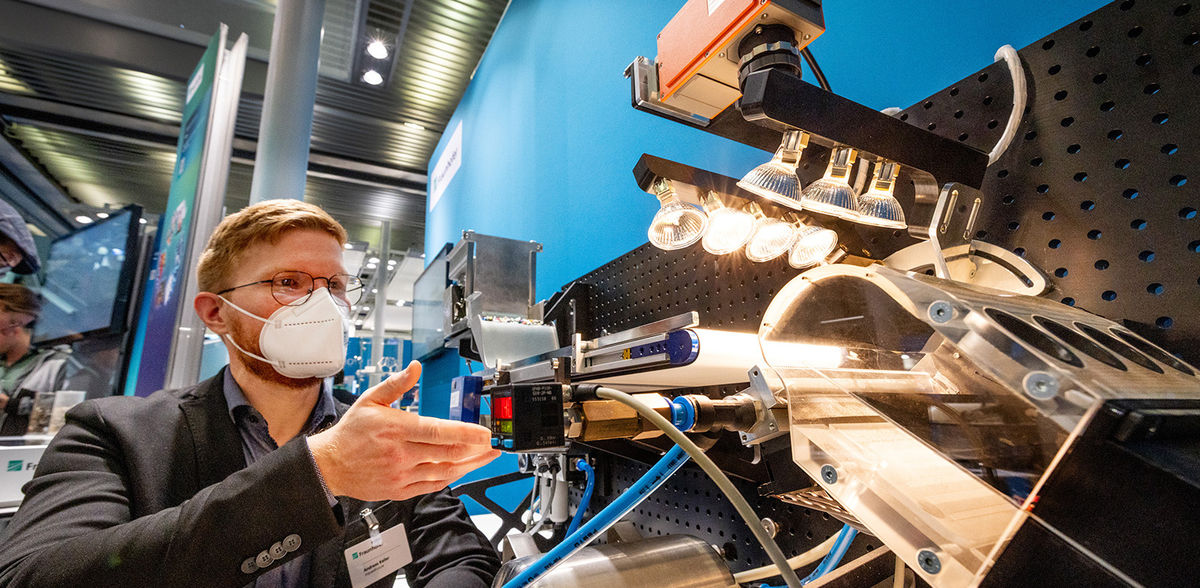

So the Waste4Future project is developing a sensor suite for sorting facilities that, among other things, can detect black particles of waste. A smart combination of different sensors from the sensor suite, including infrared and terahertz sensors, is able to determine both the parameters for sorting the material as pure as possible and how degraded the sample is. The age of the sample is relevant when assessing whether and how it is suitable for mechanical recycling. Where something is too badly damaged, it can no longer be recycled mechanically but only chemically. Both properties can be identified using the sensor suite. It detects and cross-links various physical properties of the plastics (optical, thermal, etc.) using sensor technology, some of which has been developed in-house. The data collected is cross-linked and evaluated using machine learning techniques. The sensor suite for identifying the waste is installed above the conveyor belt at a sorting facility. Compressed air nozzles then sort out either the target materials sought or the unwanted contaminants. Chlorinated plastic, such as polyvinyl chloride (PVC), can be a problem in chemical recycling. The chlorine content can lead to significant corrosion of the systems required for this, especially with chemical recycling. In general, the more pure the plastic is, the higher the quality of the recycled material.

When the plastic is detected by the sensor, huge quantities of data are generated. “Digital twins help reduce the mass of data down to essential core data and pass this on to an evaluation model we are developing as part of the project, so revamping the formerly process-based recycling chain into a material-based one,” says the researcher. Factors such as energy consumption and carbon footprint are taken into account in the process. The combination of innovative sorting technology, digital twins, machine learning and evaluation model dynamically works out for a specific amount of waste which recycling route makes the most sense from a technical, ecological and financial point of view. The evaluation model calculates the impact on the environment and gives information on matters such as how much energy is required to produce one ton of new plastic. This energy consumption is compared against the energy required for energy recovery. The evaluation model analyzes the various options for recycling plastics to enable a true comparison.

Those involved in the project are investigating potential mechanical (melt extrusion, solvent-based purification and fractionation) and chemical (solvolysis, pyrolysis, gasification) recycling processes and testing them for their suitability for different compositions of plastic waste. By the time the project ends in December 2024, it will be possible to compare components made from old plastics against new materials.

Circular economy instead of energy recovery

“A sustainable society with climate-neutral processes demands significant adjustments to value chains, which can only be achieved through innovation. We are following up on this as part of the project by working out the best possible route for recycling as well as the optimal sorting process, taking financial and ecological considerations into account, thereby contributing to a significant reduction in carbon emissions compared to energy recovery and enabling a high degree of recycling for waste containing carbon,” says the physicist.

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.