Innovative coating against ice

Development leap achieved through the use of initiated chemical vapour deposition

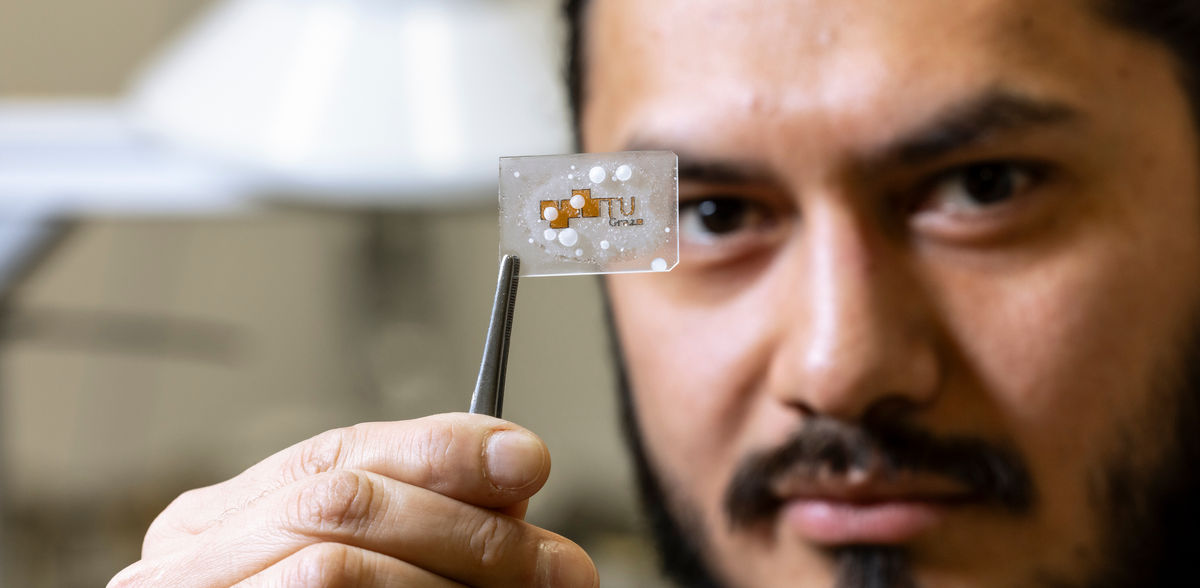

The material delays the formation of ice crystals and reduces the adhesion of ice layers. Thanks to an innovative production method, the coating is very robust and adheres to numerous surfaces.

Ice-repellent coatings have been around for some time, but until now they have been very sensitive and detach quite quickly from the surfaces they are meant to protect. A research team led by Anna Maria Coclite and Gabriel Hernández Rodríguez from the Institute of Solid State Physics at Graz University of Technology (TU Graz) has now succeeded in remedying this shortcoming. They have developed a highly ice-repellent coating that adheres to a wide variety of materials and is very resistant to abrasion.

Gradual transition of the two components

The researchers achieved this progress by using a manufacturing technology called initiated chemical vapour deposition (iCVD). This makes it possible for a strongly adhesive primer material to gradually transition into the ice-repellent compound. This stepless transition is achieved by applying the two materials as a changing gas mixture to the surface to be coated. Initially, the gas mixture consists purely of the primer material, but the proportion of the ice-repellent material is continuously increased during application, from 0 to 100 per cent. The result is a coating with a strongly adhesive underside and a top side that prevents ice crystals from sticking.

Random alignment of the molecules creates an ice-repellent effect

During their experiments, Anna Maria Coclite and Gabriel Hernández Rodríguez discovered what the ice-repellent property of their coating is based on. “The ice-repellent material consists of elongated molecules that adhere to the primer in a vertical or horizontal orientation,” explains Gabriel Hernández Rodríguez. “The thicker we applied the material, the more random the alternation between vertical and horizontal molecules became. And the more random the arrangement at the surface, the greater the ice-repellent effect.” This mechanism was previously unknown. The results were published in the journal ACS Applied Material and Interface.

Conceivable application in aviation and sensor technology

A wide range of applications are conceivable for this new type of coating, for example in the aviation industry: “Such a coating could speed up the de-icing of aircraft and use less antifreeze,” says Anna Maria Coclite. Sensors exposed to the weather that are disturbed by ice could also benefit from such coating.

Original publication

Original publication

Gabriel Hernández Rodríguez, Mario Fratschko, Luca Stendardo, Carlo Antonini, Roland Resel, Anna Maria Coclite; "Icephobic Gradient Polymer Coatings Deposited via iCVD: A Novel Approach for Icing Control and Mitigation"; ACS Applied Materials & Interfaces, 2024-2-24

Organizations

Other news from the department science

These products might interest you

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.