Easier battery production without toxic solvents: Batene receives the Max Planck-Startup Award

The Stifterverband recognizes the start-up for its technology that enhances the power and cost-effectiveness of batteries

batteries can store up to 80 percent more energy if they use Batene's technology. The start-up, which was founded out of the Max Planck Institute for Medical Research, replaces the thin contact foils of conventional batteries with fleeces of fine metal wires called BatenefleeceTM. This innovation not only significantly boosts battery performance, but also streamlines production processes, potentially reducing manufacturing costs up to 50 percent. The implementation of Batene technology holds the promise of extending the range of electric vehicles, while simultaneously driving down their price. In recognition of its innovative contribution, Batene GmbH has now been awarded the Max Planck Foundation Prize of the Stifterverband, endowed with 30,000 euros.

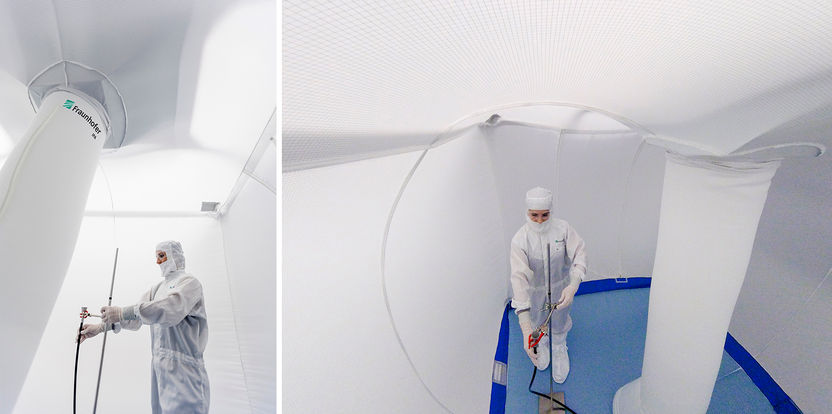

A winning team: The original Batene team in the Wendlingen hall, the current production site for nonwovens crafted from copper and aluminum. These metal fleeces serve as contact materials in batteries, markedly enhancing their efficiency and cost-effectiveness. Automotive and battery manufacturers have already expressed keen interest in this transformative technology.

© Batene GmbH

The success of the energy transition, especially within the transportation sector, hinges on the development of powerful batteries. However, current lithium-ion batteries are comparatively large and heavy in relation to their energy storage capacity, and they are also expensive. One contributing factor to this limitation is the poor conductivity of charge carriers—electrons and ions—in the active storage material of the electrodes.

To address this challenge, current batteries feature wafer-thin cells with layers of active material no thicker than 0.2 millimeters, stacked atop one another. Increasing layer thickness could lead to impractical charging and discharging times or render the battery non-functional altogether. As a result, battery manufacturers must carefully balance the desire for maximum storage capacity with the need for optimal performance, particularly in scenarios requiring rapid acceleration, such as in cars, and especially during the demanding tasks associated with starting and landing helicopters

Batene GmbH has been awarded the Max Planck Foundation Award by the Stifterverband for its innovative solution to the challenges posed by conventional batteries through the introduction of BatenefleeceTM. This groundbreaking metal fleece replaces the contact foils found in current batteries and seamlessly permeates the active material within the electrodes.

A team led by Joachim Spatz, Director at the Max Planck Institute for Medical Research and founder of Batene GmbH, has not only developed a method for manufacturing such metal fleeces, but also discovered that these fleeces facilitate significantly faster transport of both electrons and ions through battery electrodes compared to existing designs.

Easier battery production without toxic solvents

This breakthrough enables the application of active material in layers up to two millimeters thick—ten times thicker than traditional batteries—resulting in a 35 percent increase in storage capacity at very slow charging speeds. Moreover, for applications requiring rapid charging and discharging, such as in electromobility, batteries equipped with fleece electrodes can store up to 80 percent more energy than conventional counterparts.

But just as important for the industry: the introduction of the metal fleece simplifies production processes significantly, making batteries more cost-effective. Currently, the application of thin layers of active material often involves the use of toxic organic solvents, which requires extensive safety measures, consumes considerable energy, and necessitates solvent recovery efforts by battery manufacturers. In contrast, the utilization of thick electrodes with metal fleeces offers a streamlined production method. The active material can be filled into the fleece as a powder and subsequently compressed, eliminating the need for solvents and the associated safety precautions and energy-intensive drying processes.

"We firmly believe that Batene technology will significantly enhance the efficiency and cost-effectiveness of all types of batteries. It doesn't alter the chemistry involved; rather, it vastly improves the structure of battery cells. This serves to preserve valuable material resources, which are already in short supply," explains Joachim Spatz. "Receiving the Max Planck Start-Up Award reinforces our commitment to this endeavour and will facilitate the introduction of this innovation to the market."

The benefits of metal nonwovens extend not only to today's lithium-ion batteries but also to future technologies like sodium-ion or solid-state batteries, which are currently under intensive research by both scientific and industrial communities..

There is already considerable interest in the technology from national and international automotive and battery manufacturers.

"Batene has the potential to disrupt the battery market," says Patrick Cramer, President of the Max Planck Society. "The company demonstrates how findings from fundamental research can be translated into practical applications, contributing to job creation in an innovative industry."

Other news from the department business & finance

These products might interest you

Most read news

More news from our other portals

Something is happening in the chemical industry ...

This is what true pioneering spirit looks like: Plenty of innovative start-ups are bringing fresh ideas, lifeblood and entrepreneurial spirit to change tomorrow's world for the better. Immerse yourself in the world of these young companies and take the opportunity to get in touch with the founders.

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.