Research cooperation: LANXESS and IBU‑tec to develop iron oxides for LFP battery material

Reduced carbon footprint of batteries through use of local raw materials

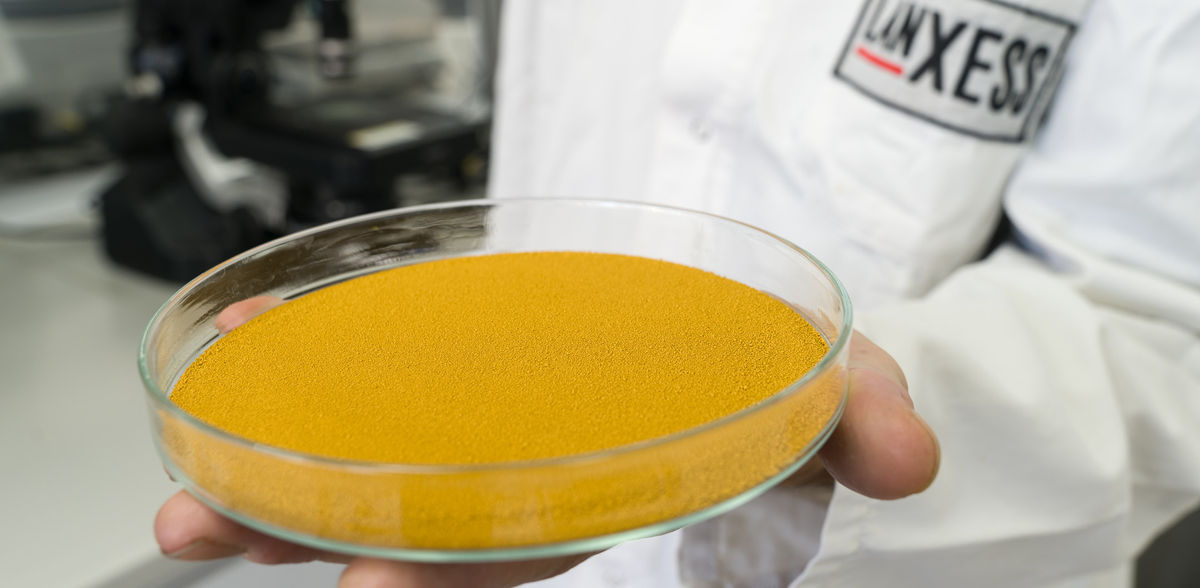

Specialty chemicals company LANXESS and battery materials manufacturer IBU-tec advanced materials have entered into a research cooperation in the battery sector. The goal of the two German companies is to develop innovative iron oxides for the production of cathode material for LFP batteries and thus increase the performance of this battery type. The companies aim to optimize the electrochemical properties of LFP batteries, such as energy density, charging speed and number of charging cycles.

More and more car manufacturers are increasingly relying on LFP (lithium/iron/phosphate) batteries for their e-vehicles - especially for volume models. Compared to NMC (nickel/manganese/cobalt oxide) and NCA (nickel/cobalt/aluminum oxide) cell chemistry systems, LFP technology offers cost advantages of up to 50 percent and promises safer use, as the system makes the batteries virtually impossible to ignite.

Strengthening European value chains

The demand for LFP in Europe is expected to grow by 20 percent per year until 2030. So far, however, this demand has been met almost exclusively by non-European suppliers. With their development, both companies aim to contribute to the establishment of an independent, robust value chain in the European LFP battery market, while at the same time reducing the carbon footprint of batteries.

IBU-tec, based in Weimar, Germany, is currently the only European manufacturer of LFP cathode material. LANXESS operates the world’s largest plant for the key raw material iron oxide in Krefeld-Uerdingen. The company has almost 100 years of experience in developing this material and can supply iron oxide particles for LFP batteries in the required size, purity, morphology and quantities.

Michael Ertl, Head of the Inorganic Pigments business unit at LANXESS, said: “As IBU-tec is currently the only European manufacturer of LFP cathode materials, the company is the ideal partner for us to develop the new material, which is a key component for batteries in e-cars and stationary energy storage systems. This is an important contribution to sustainability and the development of a European value chain in the field of battery materials.”

Jörg Leinenbach, CEO of IBU-tec, said: “With LANXESS, we are gaining one of the largest, globally positioned chemical companies as a strong partner in the battery sector. With the joint product development we will combine our expertise and together we will drive the development of the European LFP battery market and establish an independent value chain. We see this cooperation as an important step towards opening up the market. IBU-tec will inform about further material developments in the battery sector with new application possibilities in January.”

Other news from the department research and development

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.