Moondust for Solar Power

Researchers are developing an innovative production process that uses lunar regolith to create solar cells for a future lunar base

Advertisement

The construction of a lunar base as a starting point for further space exploration and future Mars missions is one of the core elements of current international space strategies. Key to this is providing a power supply that is as self-sufficient as possible. The German Space Agency at the German Aerospace Center (DLR) is now funding the joint project “SoMo – An innovative manufacturing process for solar cells made of lunar regolith” between the Chair of Space Technology at TU Berlin and JPM silicon GmbH as part of the “Research and Exploration” program with funds from the Federal Ministry for Economic Affairs and Climate Action.

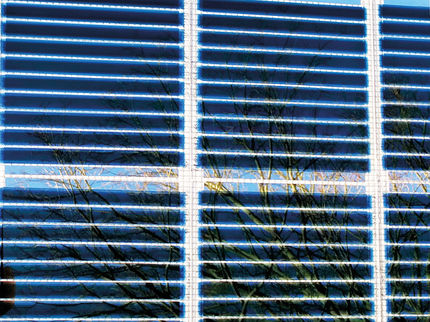

Glass sample from the lunar regolith simulant TUBS-T

TU Berlin

Dr Thomas Driebe of the German Space Agency spoke on the decision to fund the project: “Today, Germany is making an important contribution to space research and exploration through its involvement in European lunar missions and NASA’s Artemis program. This means we are now close to a manned lunar base and the question of how we can supply it with raw materials and energy. Photovoltaics plays a decisive role here. We see this as an outstanding project that brings together space research and the further expansion of terrestrial photovoltaics, and we anticipate promising results that will enable us to take a step into space itself.”

On-site production to replace expensive rocket transportation

The development of ISRU technologies is particularly important for future lunar exploration, both to increase the sustainability of lunar missions and reduce their costs. ISRU stands for "in-situ resource utilization." This involves producing products and resources such as water, oxygen, construction products, and electricity from locally available materials and resources such as lunar dust (regolith) and sunlight. The technologies involved can help provide missions with the materials and consumables they need and that would otherwise have to be supplied from Earth at great expense. According to Professor Dr. Enrico Stoll, head of the Chair of Space Technology at TU Berlin, the current cost of transporting just one kilogram of material from the Earth to the Moon is approximately one million euros. “Supplying energy to a future lunar base using the resources available on the Moon is a key area of our space research,” says Professor Stoll.

Fully functional solar cells

The SoMo project contributes to this research by using the widely available lunar dust as a raw material for the production of solar panels on the Moon. The project’s manufacturing technique enables the production of silicon cells using two widely available resources on the Moon: lunar regolith for the production of glass substrates and UV light. The end product is a silicon cell on a buffer layer of aluminum oxide. This represents the first step towards the sustainable production of fully functional solar cells on the Moon.

Simulants for moondust

The glass substrate required for the process is produced by the Chair of Space Technology at TU Berlin. Enrico Stoll's research group has developed various simulants for lunar regolith. These are powders that mimic the properties of various soil samples brought to Earth during the Apollo program. The glass is produced by melting the simulants at very high temperatures (over 1,500°C). The resulting glass is then molded and further processed by Stoll’s team. Project partner JPM Silicon GmbH then produces a silicon layer from the glass substrate, which is finally converted into a solar cell.

Sustainable use of lunar resources

“The goal of the project is to provide as self-sufficient a power supply as possible for lunar exploration projects, and at the same time achieve an appropriate level of efficiency for the solar cells,” explains project leader Juan Carlos Ginés Palomares. “At the Chair of Space Technology, we are currently conducting several research projects into lunar resources and their sustainable use. This joint research project is an important step towards realizing our vision of a self-sustaining lunar exploration to enable long-term and effective missions.”