Turning plastic trash into chemistry treasure

“The use of commodity plastics as chemical reagents is a completely new perspective on organic synthesis”

Researchers employ common plastics to kickstart radical chain reactions, creating a way to reuse plastic waste while improving process safety and efficiency.

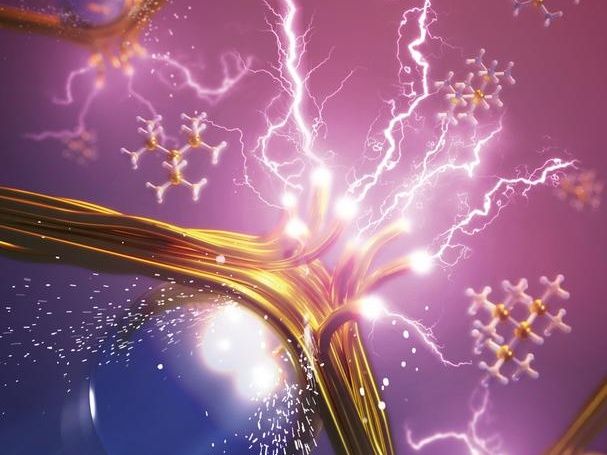

Artistic depiction of extremely reactive molecules called radicals being generated from plastic fibers.

Koji Kubota and Hajime Ito

Single-use plastics are a major environmental concern, but now, rather than being disposed of as garbage, used plastic bags from the grocery store could be utilized to carry out a reaction that can detoxify hazardous chemicals.

A team led by researchers at the Institute for Chemical Reaction Design and Discovery (WPI-ICReDD), Hokkaido University has developed a method that uses common plastic materials instead of potentially explosive compounds to initiate radical chain reactions. This approach significantly increases the safety of the process while also providing a way to reuse common plastics such as polyethylene and polyvinyl acetate. These findings have been published in the Journal of the American Chemical Society.

Researchers utilized a ball mill, a machine that rapidly shakes a steel ball inside a steel jar to mix solid chemicals. When the ball slams into the plastic, the mechanical force breaks a chemical bond to form radicals, which have a highly reactive, unbonded electron. These radicals facilitated a self-sustaining chain reaction that promotes dehalogenation— i.e., the replacement of a halogen atom with a hydrogen atom—of organic halides.

“The use of commodity plastics as chemical reagents is a completely new perspective on organic synthesis,” said Associate Professor Koji Kubota. “I believe that this approach will lead to not only the development of safe and highly efficient radical-based reactions, but also to a new way to utilize waste plastics, which are a serious social problem.”

The reuse of waste plastic was demonstrated by adding plastic shreds of a common grocery bag to the ball mill jar and successfully carrying out the reaction. The team also showed their method could be applied to the treatment of highly toxic polyhalogenated compounds, which are widely used in industry. Polyethylene was employed to initiate a radical reaction that removed multiple halogen atoms from a compound commonly used as a flame retardant, thus reducing its toxicity.

Researchers anticipate this method will garner the attention of industry due to advantages in cost and safety.

“Our new approach using stable, cheap and abundant plastic materials as initiators for radical chain reactions holds the significant potential to foster the development of industrially attractive, safe and highly efficient chemical processes,” commented Professor Hajime Ito.

Original publication

Koji Kubota, Julong Jiang, Yuri Kamakura, Reon Hisazumi, Tsubura Endo, Daiyo Miura, Shotaro Kubo, Satoshi Maeda, Hajime Ito; "Using Mechanochemistry to Activate Commodity Plastics as Initiators for Radical Chain Reactions of Small Organic Molecules"; Journal of the American Chemical Society, 2023-12-22

Most read news

Original publication

Koji Kubota, Julong Jiang, Yuri Kamakura, Reon Hisazumi, Tsubura Endo, Daiyo Miura, Shotaro Kubo, Satoshi Maeda, Hajime Ito; "Using Mechanochemistry to Activate Commodity Plastics as Initiators for Radical Chain Reactions of Small Organic Molecules"; Journal of the American Chemical Society, 2023-12-22

Organizations

Other news from the department science

These products might interest you

SPEX SAMPLEPREP 8000D MIXER/MILL® by C3 Prozess- und Analysentechnik

Experience maximum efficiency and long grinding time - The ultimate high energy ball mill for fast grinding and mixing

PULVERISETTE 5 / PULVERISETTE 7 by Fritsch

Insert the grinding bowl, start, finished: Get to know the fastest and safest Planetary Ball Mills on the market

Automatic grinding bowl clamping, imbalance control and comminution down to the nano range

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

ALTANA acquires formulated resins business from Solvay - Will be incorporated into the ELANTAS Electrical Insulation division

Evonik sells its US Jayhawk site - Company continues to intensify focus on high-margin specialty chemicals businesses

Solvay projects 35 percent capacity increase of sulfone polymer production over the next five years

Chiral Quest announces opening of new operations facility - In the Princeton/NJ area Chiral Quest intends to enlarge production of catalysts and larger scale chiral phosphines

Covestro continues production at Tarragona site - Investment of around EUR 200 million

Study finds flame retardant exposure higher in infants than adults

Styrolution Group GmbH - Frankfurt am Main, Germany

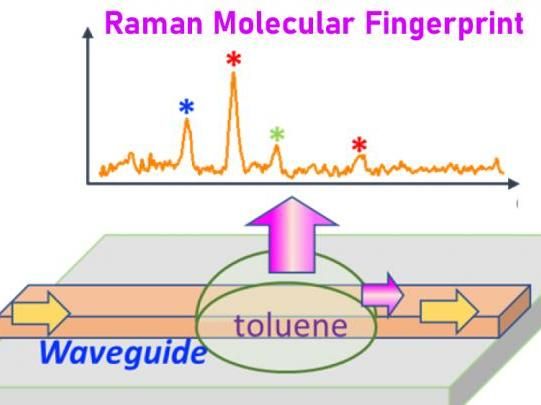

Researchers dramatically downsize technology for fingerprinting drugs and other chemicals - Tiny photonic chip could fit comfortably within the tip of a finger