Environmentally friendly non-stick coating replaces per- and polyfluorinated chemicals (PFAS) on everyday products

Whether it is pans, cutlery or packaging, per- and polyfluorinated chemicals (PFAS) have been used for coating in a wide variety of everyday products and processes for many years. Due to known risks of these substances to humans and the environment, at least a partial ban on the production and use of PFAS is expected to be implemented soon. The use of comparable alternatives is therefore essential for numerous companies. Fraunhofer IFAM specializes in fluorine-free coatings and has developed the PLASLON® technology, a PFAS-free non-stick coating that meets the required property profile and can replace the existing technology with immediate effect.

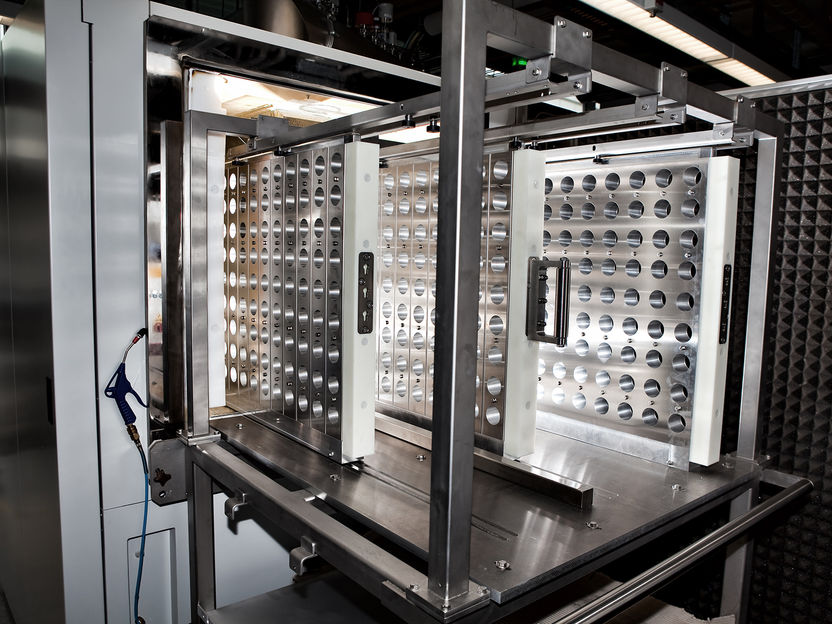

Low-pressure plasma system with easily exchangeable electrode systems, which also function as product carriers.

© Fraunhofer IFAM

PFAS are a group of several thousand individual chemicals. They do not originally occur in nature, are extremely stable and are therefore constantly accumulating in the environment. The fluorine compounds, also known as "eternity chemicals", can occur in the blood serum of humans and lead to negative health effects. For this reason, the European Chemicals Agency (ECHA) is considering a ban on the production, use and marketing of PFAS. A decision by the European Commission on this is expected in 2025, according to the German Federal Environment Agency.

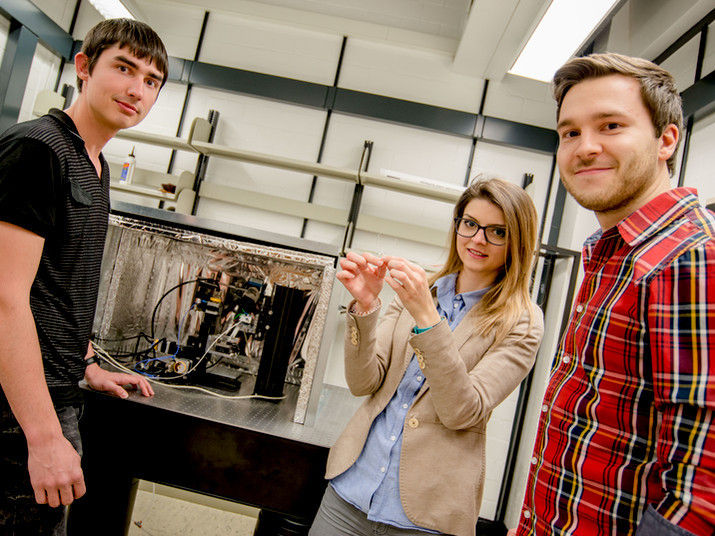

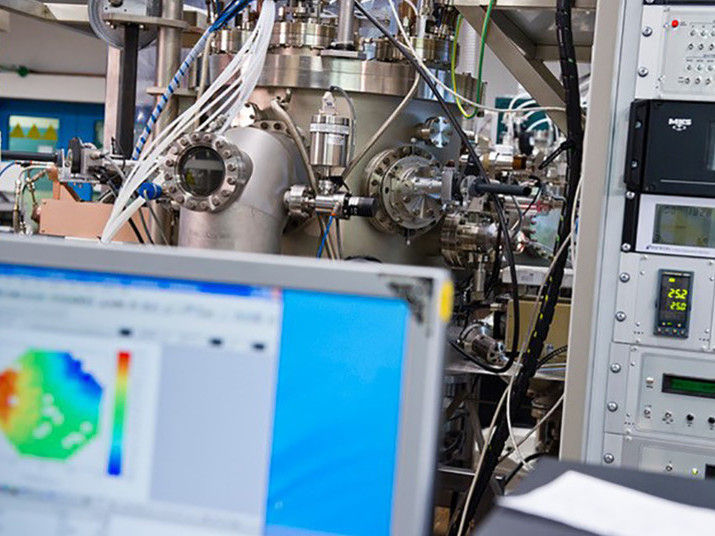

Companies that use PFAS will face challenges because of a ban. In order to maintain processes and production, alternative solutions have to be found. Plasma technology offers ideal conditions for this. The plasma coatings developed at Fraunhofer IFAM are not only fluorine-free (Zero-F), but also free of additives. They can be applied on almost all materials. Due to their property profile, some of the coatings are particularly suitable as PFAS-free non-stick coatings, sliding coatings, and hydrophobic finishes.

PLASLON® - PFAS-free non-stick coating

With the PLASLON® coating, researchers at Fraunhofer IFAM have developed a PFAS-free alternative characterized by excellent non-stick properties combined with high mechanical resistance. The coating, which is produced by means of plasma technology, is designed as a gradient layer to enable excellent adhesion to the product body on the one hand and to display optimum non-stick properties on the other. The coating is also characterized by easy-to-clean properties and is resistant to cutting and abrasion. It is non-porous and food safe. It also exhibits oleophilic behavior regarding edible oils and fats.

A unique selling point of the PLASLON® coating is that - unlike other non-stick coatings - it is also suitable for enamel, glass, stoneware, and porcelain due to its good adhesion and outstanding hardness. Products made of these materials in particular are very scratch-resistant but have poor non-stick properties.

The institute's scientists also have the necessary know-how of suitable manufacturing processes to be able to finish products economically and in large quantities. Depending on the customer's needs, various concepts are available for this, such as XXL systems or throughput systems. Combined with low energy consumption during the production, uninhibited heat transfer during use and a long service life of the coating, PLASLON® is particularly sustainable and thus trendsetting.

Most read news

Other news from the department science

These products might interest you

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Sartorius closes 2020 with strong growth - Group management raises sales target for 2025 to about 5 billion euros

A treasure map for the realm of electrocatalysts - Research into promising materials is hampered by the sheer number of possible candidates: An efficient method to solve this problem now developed

Category:Gemstones

Category:Electrochemistry

Camp_American_University

Category:Nanotechnology_institutions

George_Frederick_Kunz

Dinonylnaphthylsulfonic_acid

Brammallite