Evonik further expands production capacity for gas separation membranes

Group invests mid-double-digit million euro amount in Schörfling and Lenzing in Austria

Advertisement

Evonik will further expand capacity for production of its SEPURAN® hollow fiber membranes in Schörfling and Lenzing, Austria. The specialty chemicals company already put into operation a new hollow fiber spinning facility in Schörfling at the beginning of the year. On the occasion of the ceremonial opening of this plant, Evonik Chief Executive officer Christian Kullmann announced the construction of a further production line: "We are going full throttle for the green transformation and are investing a mid-double-digit million euro amount as the next step to grow our membranes business." Construction in Schörfling and Lenzing is scheduled to start in early 2024, with completion planned for the first half of 2025.

The growth of the membrane business clearly follows the Group's strategy. "We invest in innovative green technologies that offer superior sustainability benefits to our customers," says Kullmann. "The dynamic development of the membrane business shows that the green transformation is underway and that we are playing a key role in it." By 2030, Evonik aims to increase the proportion of revenue generated by Next Generation Solutions to more than 50 percent from currently 43 percent. Next Generation Solutions are products with demonstrably superior sustainability benefits.

With membranes for the treatment of biogas and the extraction of hydrogen, for example, Evonik is making an important contribution to the defossilization of the energy industry. The trend towards renewable energy is driving the steadily growing demand in the membrane business.

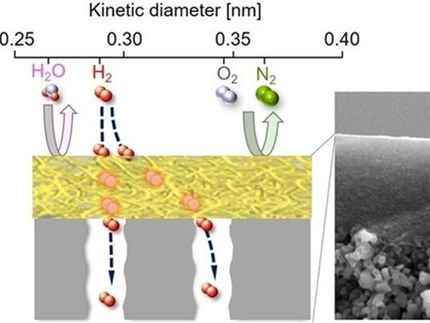

At the heart of Evonik’s SEPURAN® membrane technology are fine hollow fibers made of a high-performance polymer specially developed by Evonik that is highly resistant to pressure and temperature. The upcoming capacity expansion includes construction of an additional plant for spinning hollow fibers and the expansion of the infrastructure necessary for producing membrane modules at the Schörfling site. The neighboring site in Lenzing will expand production of the required raw material (high-performance plastic).

"The planned production expansion for SEPURAN® membranes will create around 50 new jobs in Lenzing and Schörfling," says site manager Jean-Marc Chassagne. "The investment strengthens the site's importance on international markets. With the innovative technology from Upper Austria, Evonik is driving the global transformation toward a sustainable gas economy."

Evonik’s production in Schörfling at the Attersee is already powered entirely by renewable energy. Nothing but green electricity from wind, hydropower, or biomass fuels the production facility for SEPURAN® membranes. Since the beginning of 2022, the specialty chemicals company is also covering 100 percent of its gas requirements with biomethane from regional production. By switching to environmentally friendly energy, Evonik is reducing its direct CO2 emissions in Upper Austria by around 5,000 metric tons a year.

Since the first products were presented in 2011, Evonik has steadily developed the SEPURAN® membranes business. Within twelve years, it became a globally recognized technology leader for efficient gas separation. To date, Evonik has supplied membranes to more than 1,000 reference plants worldwide for the biogas market alone.

SEPURAN® hollow fiber membranes can separate gases such as methane (CH4), nitrogen (N2), and hydrogen (H2) particularly efficiently from gas mixtures. The advantage of Evonik's membrane technology lies in the more precise separation of gases and in higher productivity. SEPURAN® N2 membranes for efficient nitrogen production are used, for example, for inerting aircraft tanks. SEPURAN® Noble membranes extract the hydrogen transported through the natural gas pipelines from the CH4/H2 gas mixture selectively at the H2 take-off points. SEPURAN® NG membranes enable efficient natural gas processing from sources with high CO2 concentration. SEPURAN® Green membranes enable efficient biogas upgrading from organic and circular substrates.