Molecular motion in tire rubber

Tyre components observed with incredible time resolution

Scientists have observed the molecular motion of rubber components typically used in automobile tires—polybutadiene and carbon black—with the world’s fastest time resolution. The study reveals a clear interaction between the two components on the atomic scale, paving the way towards improved diagnostics of tire rubber degradation and the development of materials with enhanced durability.

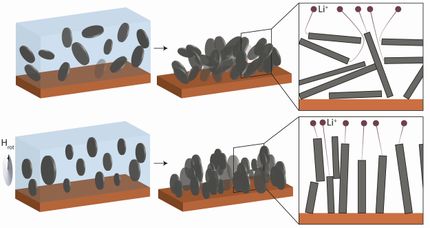

Tire rubber is a composite material that typically includes synthetic rubber, such as polybutadiene, and added nanoparticles, such as carbon black, to improve its physical properties. During driving, strong forces act on the tire, causing its components to move against each another, which can lead to wear and degradation of the material. To evaluate tire performance, it is therefore important to understand not only the static structure of the complex particle network formed by the polymer and the nanoparticles, but also their interaction and respective movements, as these dynamics directly influence material properties such as wear resistance. Because some of these molecular movements happen extremely quickly, time-resolved measurements at atomic resolution on the fastest possible time scale are critical for developing and validating dynamic models of such materials.

An international research team led by scientists from the University of Tokyo, Ibaraki University, and European XFEL has now observed the molecular motion within samples of polybutadiene and carbon black, which occurs naturally as a result of the material structure, with a time resolution of 890 nanoseconds (billionths of a second)—the fastest resolution obtained in such studies so far—at the European XFEL’s SPB/SFX instrument.

“Using the recently developed method of diffracted X-ray blinking, we simultaneously detected fast changes in the polymer chains and in the additive nanoparticles on the atomic scale,” says Tokushi Sato from European XFEL, one of the corresponding authors of the publication. “We observed a clear interaction between polybutadiene and carbon black, indicating that the mobility of polybutadiene differed significantly depending on the type of carbon black added.” Each sample contained a different kind of carbon black. The experiment revealed that, in one sample, the polybutadiene moved much faster on the carbon black particle surface than in the other—resulting in poorer properties for automobile tire performance than the sample in which the two components were more strongly bound. The results may lead to improved methods to study tire rubber degradation in the laboratory during development and thus to devise materials with enhanced durability.

Original publication

Masahiro Kuramochi, Henry J. Kirkwood, Jayanath C. P. Koliyadu, Romain Letrun, Raphael de Wijn, Chan Kim, Tomomi Masui, Kazuhiro Mio, Tatsuya Arai, Hiroshi Sekiguchi, Hiroyuki Kishimoto, Adrian P. Mancuso, Tokushi Sato, Yuji C. Sasaki; "Direct observation of 890 ns dynamics of carbon black and polybutadiene in rubber materials using diffracted x-ray blinking"; Applied Physics Letters, Volume 123, 2023-9-5

Original publication

Masahiro Kuramochi, Henry J. Kirkwood, Jayanath C. P. Koliyadu, Romain Letrun, Raphael de Wijn, Chan Kim, Tomomi Masui, Kazuhiro Mio, Tatsuya Arai, Hiroshi Sekiguchi, Hiroyuki Kishimoto, Adrian P. Mancuso, Tokushi Sato, Yuji C. Sasaki; "Direct observation of 890 ns dynamics of carbon black and polybutadiene in rubber materials using diffracted x-ray blinking"; Applied Physics Letters, Volume 123, 2023-9-5

Topics

Organizations

Other news from the department science

These products might interest you

NANOPHOX CS by Sympatec

Particle size analysis in the nano range: Analyzing high concentrations with ease

Reliable results without time-consuming sample preparation

Eclipse by Wyatt Technology

FFF-MALS system for separation and characterization of macromolecules and nanoparticles

The latest and most innovative FFF system designed for highest usability, robustness and data quality

DynaPro Plate Reader III by Wyatt Technology

Screening of biopharmaceuticals and proteins with high-throughput dynamic light scattering (DLS)

Efficiently characterize your sample quality and stability from lead discovery to quality control

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.