Muscles for soft robots inspired by nature

Materials researchers significantly improve the performance of hydrogel actuators

robots made of metal and other solid materials are already widely used in industry. But they are too rigid and cumbersome for fine-motor activities and interaction with people, such as in nursing or medicine. Intensive research is therefore already being carried out into robots made of soft materials: inspiration from nature, such as jellyfish, earthworms, fish or the human body should enable "soft robots" that can move flexibly and adapt to their environment.

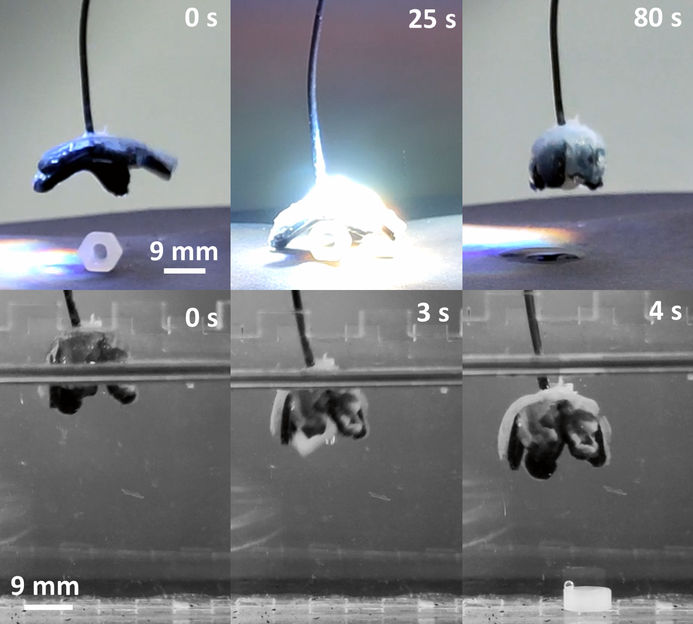

Material becomes a gripper: triggered by light, the hydrogel releases water and contracts. In the process, it encloses a small object, which it can also release again

© Margarethe Hauck

A research team from the Institute for Materials Science at Kiel University has now developed a new material system based on a hydrogel that functions similarly to a muscle. The soft material can be reduced and enlarged again in a controlled manner in a short time. Thus it could take over movement tasks in soft robotics, for example. The team recently published their results in the journal Advanced Materials.

Responsive material reacts to heat

Hydrogels, such as those used in contact lenses, are extremely elastic. They consist almost entirely of water and their mechanical properties are similar to human body tissue. Special, so-called responsive hydrogels can shrink by up to 90 per cent in response to their environment. "Our hydrogels are thermoresponsive, which means they react to heat. Above a temperature of 32 °C, they release water and thus reduce their volume," explains Dr. Margarethe Hauck, one of the first authors of the study. When the temperature drops, the hydrogel absorbs the water again and returns to its original volume.

The process can be repeated any number of times, resulting in a kind of movement. "Basically, these hydrogels have the potential to function like a human muscle," says Hauck, who did her doctorate on the topic in the graduate training programme "Materials for Brain". This makes them interesting as actuator components for the development of new types of soft robots. But until now, the entire process of changing the volume still took several weeks - far too slow for most applications.

Internal channel system transports water particularly quickly

Scientists around the world are trying to change the volume of such thermoresponsive hydrogels more quickly using various methods. The researchers from Kiel built a network of tiny tubes into their hydrogel. "This allows it to be reduced and enlarged much faster than before without losing stability. On the contrary, it can even exert up to 4,000 per cent more force," explains Lena Saure, doctoral student at the Chair of Functional Nanomaterials and also a first author.

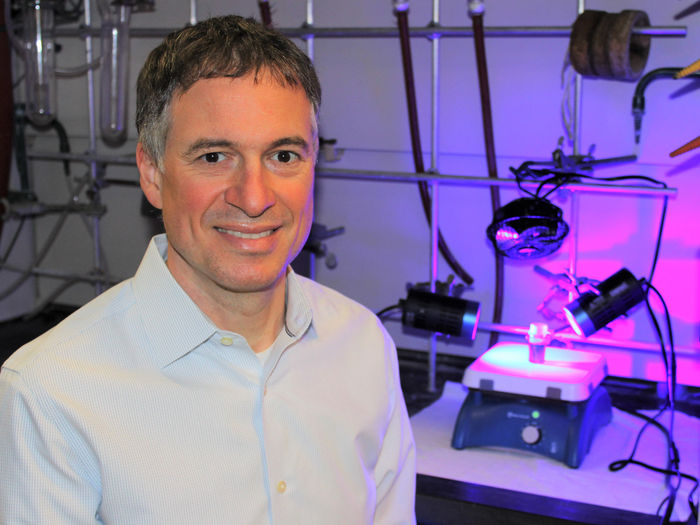

"Our approach follows nature's example," says materials scientist Dr Fabian Schütt, head of the study and the junior research group "Multiscale Materials Engineering" at the Institute of Materials Science at Kiel University. "Plants and animals have networked, hierarchically structured channel systems for effective substance and fluid transport, like the capillary system in humans. Using this principle, we can also improve the properties of soft materials."

Graphene coating enables electrical control

The numerous interconnected hollow tubes of a few micrometres in size allow the water to flow freely out of and into the hydrogel, thus enabling a rapid change in its volume. An extremely thin graphene coating also makes the tubes electrically conductive. This way the researchers can heat the hydrogel with an electric current and control the water transport at the touch of a button. "This is a crucial aspect when it comes to the practical application of such soft actuators," Schütt emphasises. As a result, the entire volume change now only takes a few hours instead of weeks "We are of course working on further accelerating this process." This is also possible with a directed light beam, explains Lena Saure. "This has the advantage that the movement can be controlled wirelessly, so it is very flexible."

The team can adapt the hydrogel for different applications. For example, a different structure of the tubes or a higher or lower concentration of graphene changes the reaction times or the forces exerted. Nicola Pugno, Professor of Solid State and Structural Mechanics at the University of Trento, Italy, and currently a guest at Kiel University as a Humboldt Research Award Winner, calculated how a change of the material structure affects the properties of the hydrogel. Colleagues from the Helmholtz Centre Hereon and the Technical University of Dresden were also involved in the collaboration.

Medical applications are also possible

"For the first time, we can move a hydrogel with both speed and force. Together with its responsive properties, with which it reacts independently to external stimuli, this brings us a decisive step closer to intelligent high-performance materials for soft robotics," says Professor Rainer Adelung, head of the chair and the Research Training Group, highlighting the significance of the results. Due to the tissue-like properties of the hydrogel, applications in the medical field in particular are conceivable, such as in robot-assisted surgery, artificial tissue construction or also as an implant for controlled drug release in the human body.

Original publication

Margarethe Hauck, Lena M. Saure, Berit Zeller‐Plumhoff, Sören Kaps, Jörg Hammel, Caprice Mohr, Lena Rieck, Ali Shaygan Nia, Xinliang Feng, Nicola M. Pugno, Rainer Adelung, Fabian Schütt; "Overcoming Water Diffusion Limitations in Hydrogels via Microtubular Graphene Networks for Soft Actuators"; Advanced Materials, 2023-8-17