BASF strengthens R&D with more powerful supercomputer

New high-performance computer is the world’s largest supercomputer for industrial chemical research

BASF has started up a new supercomputer at its Ludwigshafen site to replace the existing one. With 3 petaflops of computing power, the new supercomputer is considerably more powerful than its 1.75 petaflop predecessor.

Dr. Melanie Maas-Brunner, member of the Board of Executive Directors and Chief Technology Officer of BASF (left), and Dr. Stephan Schenk, Product Manager High Performance Computing at BASF, at BASF's new supercomputer.

BASF SE

“Digital technologies are among the most important instruments to further expand our research and development capabilities,” said Dr. Melanie Maas-Brunner, member of the Board of Executive Directors and Chief Technology Officer of BASF. As one example, she noted that above-average computing power is required these days to work out the most promising polymer structures from thousands of possibilities. “Over the past five years, we have worked very successfully worldwide with our supercomputer Quriosity. It enabled us to considerably shorten the development time for innovative molecules and chemical compounds and thus accelerate the market launch of new products,” Maas-Brunner said. “But the computing capacity was no longer sufficient. Moreover, the complexity of our research projects and thus the demands on the supercomputer have increased. We therefore decided to invest in a new high-performance computer.”

The new supercomputer was manufactured by Hewlett Packard Enterprise (HPE) and works with AMD processors (CPUs). It has an innovative cooling concept based on warm-water cooling. The system absorbs the heat directly where it is generated in the supercomputer and transports it away, which significantly reduces the energy required and therefore the operating costs. The new BASF supercomputer, named Quriosity like its predecessor, is the world’s largest supercomputer used in industrial chemical research. The previous supercomputer will be refurbished by HPE, with a recovery rate of more than 95 percent.

BASF also relies on additional cloud computing power when needed

In addition to its own on-site supercomputer, BASF also plans to use cloud computing power. “This hybrid solution offers us the best possible technical and operational flexibility,” said Maas-Brunner. “It allows us to handle requests requiring exceptionally large processing power as well as work on special tasks that our own supercomputer is not designed for.”

Supercomputer enables fundamentally new research approaches

As a digital tool, the supercomputer is an enormous timesaver. Calculations that would have taken around a year in the past can be carried out by a supercomputer in just a few days. This has not only reduced product development times: “We were able to identify and utilize previously hidden connections to drive completely new research approaches,” said Maas-Brunner. “Modeling, virtual experiments and simulations are becoming increasingly complex and require more computing power. With the new supercomputer, which is approximately twice as fast, we can now provide our researchers with the necessary computing power.”

Entire company using Quriosity since 2017

The Quriosity supercomputer has been deployed at BASF since 2017. Since then, it has carried out an average of 20,000 tasks per day and is used by more than 400 employees worldwide. In the personal care business area, for example, the supercomputer’s complex simulations help researchers to better understand the composition of personal care products and more precisely predict which cosmetic ingredients harmonize optimally together to achieve the desired effect. Simulations also help to plan and optimize reaction processes. For example, the distribution of substances and the temperature in a reactor can be simulated and this information can be used to continuously improve production. At an early development stage for crop protection products, using molecular modeling the supercomputer can quickly identify suitable compounds which will be effective and environmentally sound. However, the supercomputer is also used in projects outside of research and development. It helps, for example, to optimize the fluid dynamics of plant components in production operations.

Most read news

Other news from the department research and development

These products might interest you

New

New

Data Management Platform by LabV Intelligent Solutions

Turn data into better products

Maximum efficiency in the laboratory with LabV’s AI-powered data management platform

ALPHA II by Bruker

Chemical analysis made easy: compact FT-IR system

Increase the efficiency of your routine analyses with user-friendly technology

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Category:Iron_minerals

Delépine_reaction

Vulcan officially opened its Lithium Extraction Optimisation Plant - Europe’s first plant for fully domestic lithium chemicals production, to secure Europe’s lithium supply chain for Battery Electric Vehicle manufacturers

HLA-DR

Secondary_electrons

Perfluorooctanoic_acid

Researchers develop sensors that operate at high temperatures and in extreme environments - Sensitive, reliable and durable sensors created for multiple industries

Category:Enzymes_by_cofactor

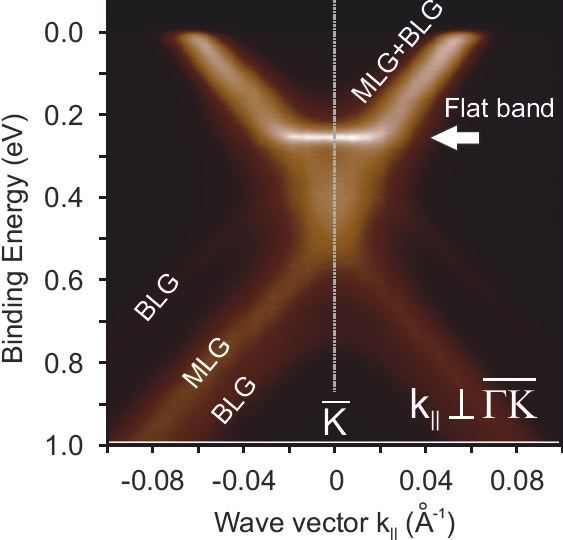

Graphene on the way to superconductivity

A simple, cheap material for carbon capture, perhaps from tailpipes - Porous material from melamine efficiently captures CO₂ from flue gases