Scientists streamline a widely used chemical reaction, creating new manufacturing opportunities

This research should have a far-reaching impact: it allows scientists to forge valuable carbon-carbon bonds used in the pharmaceutical and agrochemical industries, and beyond

A team of scientists from the University of Ottawa has developed an innovative technique to manufacture complex chemical structures from easily accessible substrates, making it one of the simplest and most practical methods for converting alcohols into their arylated equivalents.

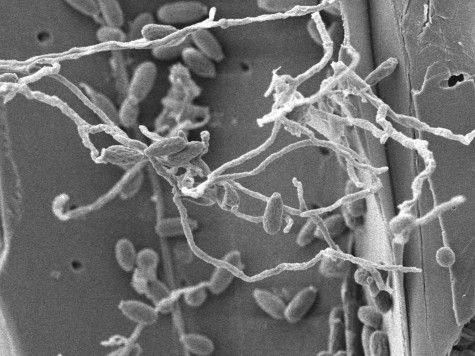

Symbolic image

Computer-generated image

This innovative method for performing the reaction, namely the deoxygenative Suzuki-Miyaura arylation of aliphatic alcohols, uses two distinct metal catalysts. Their reaction operates under mild reaction conditions with minimal waste products and is expected to have a significant impact on the creation of new molecules. As a result, it will contribute to advances in pharmaceutical, agrochemical, and related industries.

This research was carried out at the University of Ottawa’s Newman Lab under the supervision of Professor Stephen G. Newman, an associate professor of chemistry and biomolecular sciences at the Faculty of Science who holds a Tier 2 Canada Research Chair in Sustainable Catalysis. The lead author of the research was Adam Cook, a fifth-year PhD candidate, and the second author was Piers St. Onge, a third-year PhD candidate.

“The chemical reaction that we have developed, making extensive use of the high-throughput labs in uOttawa’s Centre for Catalysis Research and Innovation, eliminates previous limitations in Suzuki-Miyaura arylations by offering a surprisingly simple method to achieve the direct derivatization of a broad range of easily accessible alcohols. By using these molecules as starting materials instead of more established organohalides, this method generates water as a waste product rather than metal-halide salts. This reaction not only provides an effective method for generating complex, medicinally relevant structures from accessible materials, but also contributes to fundamental developments in how chemical feedstocks may be directly transformed into important materials using catalysis,” explains Cook.

Current methods for Suzuki-Miyaura arylation, one of the most widely used chemical reactions in the world, require multiple synthetic steps to obtain the necessary starting materials. By developing a method that allows naturally abundant alcohols to be used directly in these transformations, “we eliminate the need for these wasteful and time-consuming synthetic steps, thereby streamlining the process of converting naturally abundant substances into value-added products. Additionally, we were able to pursue a unique mechanistic hypothesis on route towards this goal through cross-coupling reactions via an SN1-type pathway,” says Cook.

This is a previously underexplored topic in synthetic chemistry and the team of researchers hopes that their work will serve as a valuable inspiration to all scientists. “No matter how ‘out there’ your hypothesis may be, high-throughput experimentation can help you reach conclusions in a rapid and comprehensive manner,” concludes Cook.

By harnessing the power of this new technique, scientists can now create a wide range of arylated alcohols with greater efficiency and precision than ever before.

Original publication

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.