Half-cell composite: New cell concepts for the large-scale mass production of PEM electrolyzers

Advertisement

Researchers at the Fraunhofer Institute for Solar Energy Systems ISE in Freiburg have developed and patented an advanced cell and stack design for electrolyzers. This novel half-cell composite reduces the material and manufacturing costs for PEM electrolyzers and thus enables large-scale mass production. Fraunhofer ISE will present this half-cell composite along with other innovations for the hydrogen economy from April 17 to 21, 2023 at the Hannover Messe.

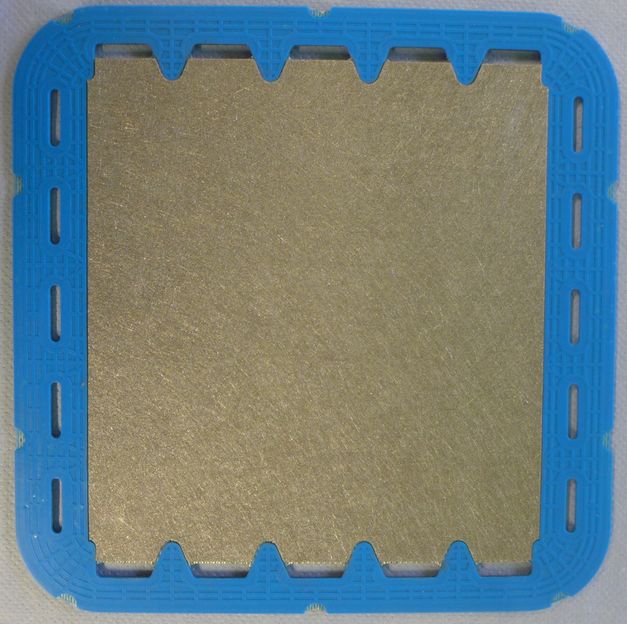

Novel half-cell composite for a PEM electrolysis cell, consisting of a porous base element, metal mesh, a porous transport layer, and an inserted joining compound of elastomer to form the sealing and channel structures.

Fraunhofer ISE

To enable the production of competitive stacks for PEM electrolysis in high volumes in the near future, innovative steps are required in both design and manufacturing. The half-cell composite developed at Fraunhofer ISE now combines the functionality of the individual components of conventional designs, such as the enclosure, sealing element, channel structures for media supply, and porous transport layer, in just one component – but without using an additional frame part. The advantages of using the half-cell composite are manifold: it reduces material and manufacturing costs, uses fewer components, and thus simplifies assembly. It also offers new possibilities such as area scaling, automated manufacturing processes, and simplified quality inspection of a half-cell composite before assembly.

Positive results from feasibility analysis

On an active area of 150 cm2, the researchers were able to demonstrate that the half-cell composite is capable of withstanding pressure and temperature cycling loads on the anode and cathode of up to 10 bar and 80°C during operation without any significant loss of performance. Based on these positive results from the feasibility analysis, a patent application was filed for the new design and manufacturing process. Currently, the aim is to scale up to larger cell areas of up to 600 cm2 with higher hydrogen gas pressure in order to achieve an industrially relevant design with power densities comparable to those in the feasibility analysis.

Hydrogen and its derivatives are an important pillar in a sustainable global energy trading system, as they can store large amounts of energy over long periods of time. They can also be transported by ship or pipeline and will soon be able to replace fossil fuels in all energy-consuming sectors. Hydrogen is also the base molecule for the production of renewable synthetic fuels and chemicals. Moreover, the proton exchange membrane (PEM) electrolysis process that splits water into hydrogen and oxygen is a dynamic process that can be flexibly operated with electricity from renewable sources. For 30 years, Fraunhofer ISE has been working on various design and production engineering issues related to PEM electrolysis.

Innovations for the Hydrogen Economy from April 17–23, 2023 at the Hannover Messe in Hall 13, Stand D35

Other innovations will also be presented at the Fraunhofer ISE booth at the Hannover Messe, such as a membrane electrode unit for PEM fuel cells produced by the decal process, with catalyst layers manufactured using a flatbed screen-printing machine. The Institute’s researchers will also demonstrate the characterization of cell components and lifetime tests using a test fuel cell and a power-to-X cube illustrating the relative energy density of different hydrogen-based energy carriers compared to unpressurized, compressed, or cryogenic liquefied hydrogen.