A greener alternative for aviation fuel

PSI and Swiss start-up company launch pilot plant for synthetic kerosene

The Paul Scherrer Institute PSI and the Swiss start-up Metafuels are developing a new process for producing sustainable aviation fuel (SAF). They are now collaborating on the construction and operation of the first pilot plant on the PSI campus to validate the technology and prepare it for large-scale commercial deployment in the near future.

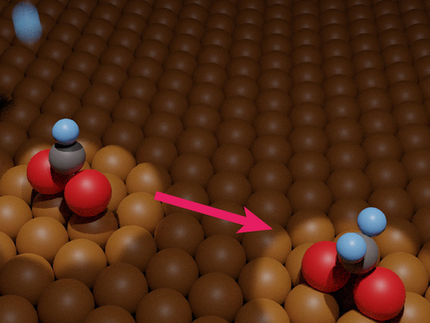

Symbolic image

Computer-generated image

Leigh Hackett (left) and Saurabh Kapoor (right) from Metafuels and Marco Ranocchiari from PSI (centre) at the ESI platform. A new pilot plant is being built here in the form of two container modules for producing synthetic kerosene from renewable resources.

Mahir Dzambegovic, Paul Scherrer Institut

PSI and Metafuels have set themselves the goal of developing and marketing an efficient process for production of affordable synthetic kerosene from renewable resources. The plan is to produce a high-quality aviation fuel using water, renewable electricity and sustainably sourced carbon dioxide. This sustainable alternative is compatible with existing jet engines, either as a blend to traditional fossil-based kerosene or eventually as a primary fuel. Working with the Metafuels team, PSI researchers have come up with a catalytic process that not only avoids the use of fossil feedstocks, but also offers superior selectivity, in other words improving the yield/conversion as compared to alternative SAF technologies. Furthermore, it enables renewable energy to be used more efficiently than in alternative SAF processes. PSI and Metafuels scientists want to use the new proprietary fuel aerobrewTM to close the carbon cycle and achieve net zero in air transport.

“Compared with traditional fuel, our technology has the potential to reduce life cycle carbon emissions by 80 to 95 percent depending on the production site,” explains Saurabh Kapoor, co-founder of Metafuels. The carbon dioxide required for the technology is sourced either from direct air capture (DAC) or from non-food biomass such as forestry or crop residues. Water electrolysis produces green hydrogen using renewable electricity such as from wind or solar facilities. “We use hydrogen and carbon dioxide to produce synthetic kerosene via intermediary green methanol.”

Long-term collaboration

For more than a decade now, the co-founders of Metafuels have been working on developing strategies and technologies to support the transition from fossil fuels to renewable energy sources. The three co-founders, Leigh Hackett, Saurabh Kapoor and Ulrich Koss, not only have tremendous scientific and commercial expertise in this field, but also extensive experience in the energy sector as a whole. They have worked previously on complex challenges associated with decarbonisation of energy systems. The aviation industry now offers them a fresh challenge.

Metafuels approached PSI with a definitive business plan and a technology path. “Can you do this sort of thing?” was the seemingly simple question. “First of all, we obviously had to carry out many relevant experiments in the laboratory,” recalls Marco Ranocchiari, Head of the Energy System Integration (ESI) experimental platform at PSI. “It worked, and we could confirm our scientific concept. We were able to use a catalytic reaction to develop a process for producing synthetic kerosene from green methanol and at the same time achieve significantly better selectivity than with the alternative SAF technologies.”

Metafuels and PSI are now progressing the next phase of the project during which a pilot plant will be constructed and operated. The pilot plant will take the form of two container modules to be installed at the ESI platform on the PSI campus and integrated into the existing infrastructure. The objective is to validate the technology so that it can be prepared for large-scale commercial use in the near future.

PSI, in partnership with industry and other research partners, uses the ESI platform to develop and demonstrate processes that promote a carbon-neutral energy system. The focus here is on energy conversion processes that convert renewable energy and feedstocks into a usable energy sources for a wide range of applications including transportation fuels.

The most energy-intensive form of travel

Air travel is responsible for around two to three percent of global CO2 emissions. Despite greater awareness of the environmental impact of flying, public appetite for air travel remains high and air traffic is set to increase further. To achieve the goals of the Paris Agreement on Climate Change and make air travel carbon neutral over the coming years, intensive research into alternatives is already under way.

Alternatives to synthetic kerosene do exist, such as batteries and hydrogen. However, the sort of lithium-ion batteries used in electric cars have a very low gravimetric energy intensity and therefore require a huge amount of mass in order to supply the required energy. For mid- and long-haul flights, where every kilogram counts, batteries are simply too heavy. Furthermore, huge adjustments to airport logistics would be needed for rapid and simultaneous charging of many aircraft.

On the other hand, although liquid hydrogen has a higher gravimetric energy density than traditional kerosene, its volumetric energy density is around four times lower. Hydrogen-powered aircraft therefore require a bigger tank volume in order to deliver the corresponding amount of energy. To overcome this problem, Airbus, for example, is developing a hybrid technology that burns hydrogen in gas turbines on the one hand and converts it into electricity in fuel cells on the other. However, this would involve a complete redesign of airplanes, including fuel systems and the jet propulsion unit.

“The advantage of liquid synthetic kerosene is that it can be integrated straight into the existing airport infrastructure and can be used in conventional jet engines,” explains Marco Ranocchiari. “So no need to replace the existing fleet of aircraft, and fossil-based kerosene can be gradually replaced by synthetic kerosene.”

However, CO2 emissions only account for around a third of the environmental impact of air travel. The formation of condensation trails, for example, is just as important. As they burn fossil kerosene, jet engines also emit soot particles and other condensation nuclei. At cold temperatures and high altitudes these instantly form ice crystals that appear as condensation trails in the sky. Under certain conditions this can lead to the formation of artificial clouds, known as aircraft-produced contrail cirrus clouds. Although some of these clouds allow visible sunlight to pass through almost unimpaired, they reflect and absorb the infrared rays from the Earth’s surface very efficiently, preventing the radiation from escaping into outer space. “The molecular composition of synthetic fuels makes it possible to manipulate the combustion process and significantly reduce the formation of soot particles, for example,” explains Marco Ranocchiari. The latest research results indicate that this not only helps reduce the planet’s net warming, but also improves local air quality at airports.

Other news from the department research and development

Most read news

More news from our other portals

Something is happening in the chemical industry ...

This is what true pioneering spirit looks like: Plenty of innovative start-ups are bringing fresh ideas, lifeblood and entrepreneurial spirit to change tomorrow's world for the better. Immerse yourself in the world of these young companies and take the opportunity to get in touch with the founders.