Repairing instead of throwing away

Gamechanger: Scientists pave the way for remanufacturing battery systems

Bayreuth engineers have found a new way to analyse the condition of batteries. It shows quickly and without effort whether a battery needs to be completely replaced or whether it is sufficient to replace only one of the battery cells it contains. Until now, this could only be determined by extensive measuring procedures.

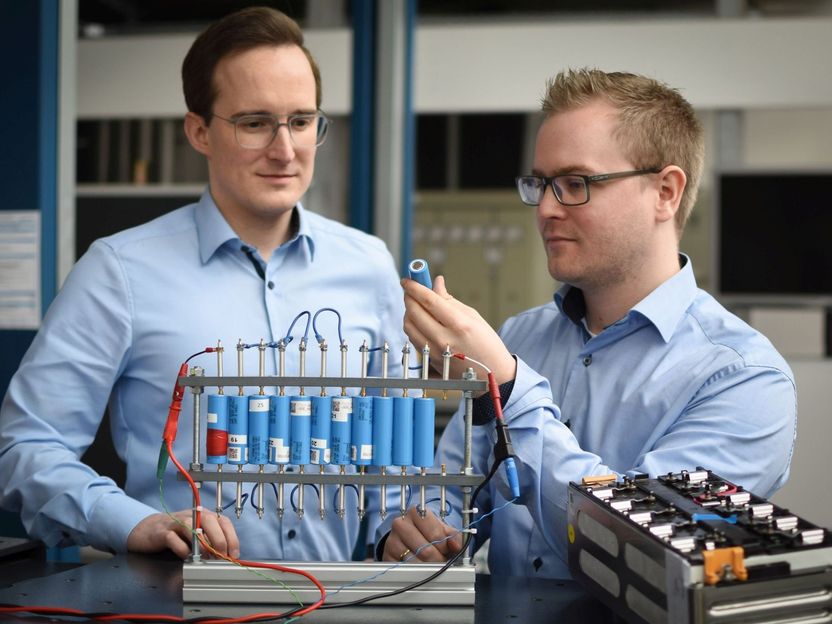

The focus of Tom Rüther (r.) and Gregor Ohnemüller is on the remanufacturing of battery packs.

Jürgen Rennecke, UBT

If a battery - whether in a cordless screwdriver, electric bicycle or e-car - no longer has sufficient energy or power, it has obviously reached the end of its life. "If you could then simply determine that only a single cell, not the entire battery, is at its end of life, you would only have to replace it, not the entire battery pack," reports Tom Rüther, research associate at the Chair of Electrical Energy Systems and the Bavarian Centre for Battery Technology (BayBatt) at the University of Bayreuth. But: "Deciding on the best circular economy option for aged or defective battery packs - i.e. repairing them first, reprocessing them for further use instead of subsequent recycling - has so far required comprehensive measurements, analyses and a corresponding data basis," says Rüther. Together with colleagues under the leadership of Prof. Dr-Ing. Danzer, he has now presented an alternative and published the findings on it in the specialist journal "Applied Energy".

Repairing instead of throwing away

In Bayreuth, the BMBF project ReDesign of the greenBatt competence cluster is working on improvements towards the circular economy in the battery sector. The main focus here is on the remanufacturing of battery packs: this refers to the replacement of individual (partial) modules or cells that are defective or show different ageing behaviour compared to the rest of the battery units. Whether there is a significant disparity in the condition of the battery packs or whether all cells have aged in the same way has so far been detected by complex measurements.

In Bayreuth, this is simplified by digitalisation: virtual battery modules are created based on the measurement of individual cells of the same type. The fluctuations from cell to cell are determined at the beginning of the service life. This results in a kind of "ideal-type battery module" taking statistical fluctuations into account. For quantitative and qualitative analysis, this is a novel comparative analysis approach. The characteristics of the cells connected in series are examined and compared with those of an unevenly aged interconnection. For the most promising traits, a detailed sensitivity analysis is performed, examining the influence of cell-to-cell variations, ageing conditions and ageing mechanism. The feature with the highest sensitivity, the so-called low-frequency minimum, is able to detect individual outliers within a large number of serially connected cells. This is the first time that inhomogeneities within a battery pack are specifically detected. Rüther summarises: "We have thus found a method to find out economically less costly than before whether a battery module has aged unevenly, which gives us new options for action when evaluating different recycling management options."

Gamechanger

"For the remanufacturing of battery modules or systems, e.g. from electromobility, and the further use of suitable cells or modules instead of scrapping them, condition assessment is an essential prerequisite. Corresponding analysis methods are therefore important door openers for value retention and further use," sums up Dr.-Ing. Bernd Rosemann, Academic Director at the Chair of Environmental Production Engineering and Project Manager of the BMBF project Redesign at the Bavarian Centre for Battery Technology (BayBatt) at the University of Bayreuth.

This sets Bayreuth's research apart from the other goals of the BMBF's greenBatt research cluster: these are primarily concerned with material recycling, i.e. the recovery of materials and substances from batteries and their return to the material cycle. The greenBatt team at BayBatt, however, is deliberately dedicated to remanufacturing, i.e. reprocessing at the parts or module level and thus making batteries that are supposedly at the end of their life usable again.

Original publication

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.