Tens of thousands of feasible catalysts on the diameter of a hair

Novel methods enable us to produce countless new materials in one step and to analyse them promptly

When searching for catalysts for the energy transition, materials consisting of at least five elements are considered highly promising. But there are theoretically millions of them – how do we identify the most powerful one? A Bochum-based research team led by Professor Alfred Ludwig, head of the Materials Discovery and Interfaces Department (MDI), has succeeded in placing all possible combinations of five elements on a carrier in a single step. In addition, the researchers developed a method to analyse the electrocatalytic potential of each of the combinations in this micromaterial library in high throughput. This is how they hope to speed up the search for potential catalysts by a considerable degree. The team from Ruhr University Bochum published its findings in the journal Advanced Materials from 21 December 2022.

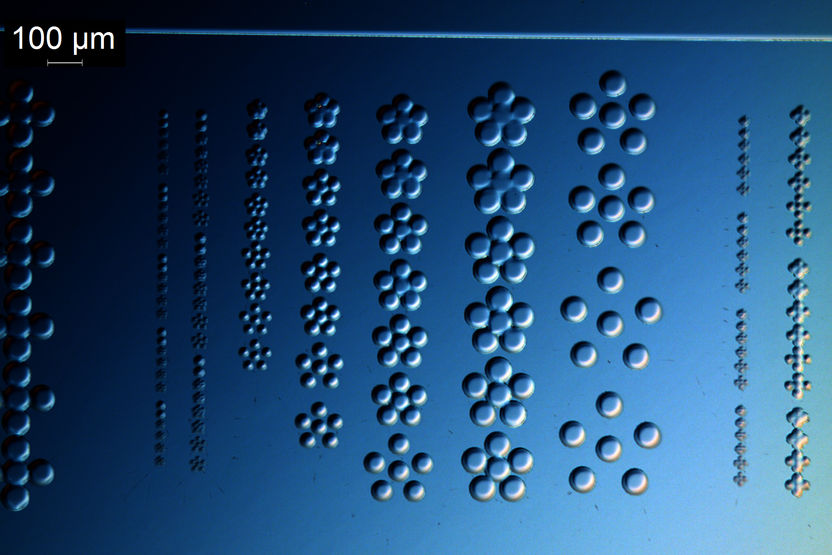

Within each collection of points is a single micro-library - each of which contains a composition variation.

© Lars Banko

A complete five-element material system on a single carrier

For the production of material libraries of so-called high entropy alloys, the Bochum researchers employ a sputtering process. In this process, all of the starting materials are simultaneously applied to a carrier from different directions. The starting materials are deposited in different mixing ratios on each part of the carrier. “In the current project, we’ve refined this process by using pinholes in such a way that each material mixture is only deposited in a tiny spot of about 100 micrometres in diameter on the carrier,” describes Alfred Ludwig. This is roughly equivalent to the diameter of a human hair. “By miniaturising the material libraries, we are now able to accommodate a complete five-component system on a single carrier – this constitutes immense progress,” adds Dr. Lars Banko from the MDI Department, who recently became head of the EXIST-funded start-up project xemX.

Research with hanging drops

To study the materials created with this technique, the researchers use what is known as scanning electrochemical cell microscopy (SECCM). This involves measuring the electrochemical properties of the material at a specific point via a hanging nanodroplet of an electrolyte measuring one thousandth the diameter of a hair. “This means we can use high-throughput methods to pinpoint the candidates with the highest catalytic activity, where a more detailed analysis seems worthwhile,” says Professor Wolfgang Schuhmann, head of the Department of Analytical Chemistry at Ruhr University Bochum.

Using these methods, the researchers are hoping to efficiently search through the plethora of possible materials for new catalysts in order to identify candidates that are particularly active as catalysts. Catalysts are needed, for example, for energy conversion processes that could enable us to use green hydrogen on a large scale as an environmentally friendly energy carrier.

Original publication

Original publication

Lars Banko, Emmanuel Batsa Tetteh, Aleksander Kostka, Tobias Horst Piotrowiak, Olga Anna Krysiak, Ulrich Hagemann, Corina Andronescu, Wolfgang Schuhmann, Alfred Ludwig: Microscale combinatorial libraries for the discovery of high-entropy materials; Advanced Materials, 2023

Topics

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.