‘Smart plastic’ material is step forward toward soft, flexible robotics and electronics

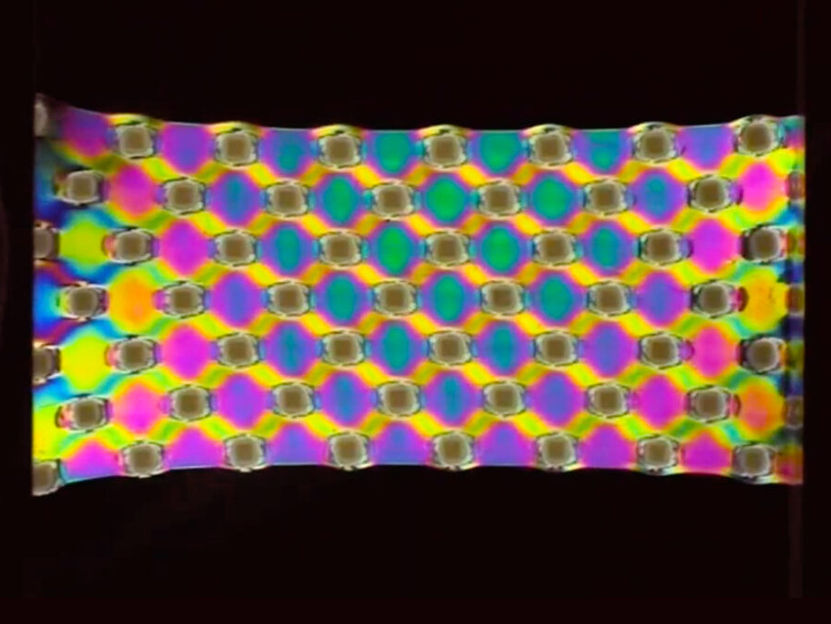

A new plastic-like material can be manipulated to be soft and stretchy or hard and rigid with only the application of a catalyst and visible light

Inspired by living things from trees to shellfish, researchers at The University of Texas at Austin set out to create a plastic much like many life forms that are hard and rigid in some places and soft and stretchy in others. Their success — a first, using only light and a catalyst to change properties such as hardness and elasticity in molecules of the same type — has brought about a new material that is 10 times as tough as natural rubber and could lead to more flexible electronics and robotics. The findings are published in the journal Science.

A new plastic-like material developed by researchers at The University of Texas at Austin can be manipulated to be soft and stretchy or hard and rigid with only the application of a catalyst and visible light.

University of Texas at Austin

“This is the first material of its type,” said Zachariah Page, assistant professor of chemistry and corresponding author on the paper. “The ability to control crystallization, and therefore the physical properties of the material, with the application of light is potentially transformative for wearable electronics or actuators in soft robotics.”

Scientists have long sought to mimic the properties of living structures, like skin and muscle, with synthetic materials. In living organisms, structures often combine attributes such as strength and flexibility with ease. When using a mix of different synthetic materials to mimic these attributes, materials often fail, coming apart and ripping at the junctures between different materials.

Oftentimes, when bringing materials together, particularly if they have very different mechanical properties, they want to come apart,” Page said. Page and his team were able to control and change the structure of a plastic-like material, using light to alter how firm or stretchy the material would be.

Chemists started with a monomer, a small molecule that binds with others like it to form the building blocks for larger structures called polymers that were similar to the polymer found in the most commonly used plastic. After testing a dozen catalysts, they found one that, when added to their monomer and shown visible light, resulted in a semicrystalline polymer similar to those found in existing synthetic rubber. A harder and more rigid material was formed in the areas the light touched, while the unlit areas retained their soft, stretchy properties.

Because the substance is made of one material with different properties, it was stronger and could be stretched farther than most mixed materials.

The reaction takes place at room temperature, the monomer and catalyst are commercially available, and researchers used inexpensive blue LEDs as the light source in the experiment. The reaction also takes less than an hour and minimizes use of any hazardous waste, which makes the process rapid, inexpensive, energy efficient and environmentally benign.

The researchers will next seek to develop more objects with the material to continue to test its usability.

“We are looking forward to exploring methods of applying this chemistry towards making 3D objects containing both hard and soft components,” said first author Adrian Rylski, a doctoral student at UT Austin.

The team envisions the material could be used as a flexible foundation to anchor electronic components in medical devices or wearable tech. In robotics, strong and flexible materials are desirable to improve movement and durability.

Original publication

Other news from the department science

These products might interest you

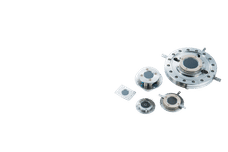

Ionendetektoren für Massenspektroskopie by Hamamatsu Photonics

Innovative detector solutions for

mass spectrometry

Unique devices for the next generation of mass spectral analysis

Mikroskopie-Zubehör by AHF analysentechnik

Optimize your fluorescence microscopy with premium accessories

Discover next generation optical filters and LED light sources

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

WACKER Starts Up New Silicon-Metal Production Facility in Norway

Turning plastic trash into chemistry treasure - “The use of commodity plastics as chemical reagents is a completely new perspective on organic synthesis”

ALTANA acquires formulated resins business from Solvay - Will be incorporated into the ELANTAS Electrical Insulation division

Evonik sells its US Jayhawk site - Company continues to intensify focus on high-margin specialty chemicals businesses

Solvay projects 35 percent capacity increase of sulfone polymer production over the next five years

Chiral Quest announces opening of new operations facility - In the Princeton/NJ area Chiral Quest intends to enlarge production of catalysts and larger scale chiral phosphines

Covestro continues production at Tarragona site - Investment of around EUR 200 million

Study finds flame retardant exposure higher in infants than adults

Styrolution Group GmbH - Frankfurt am Main, Germany

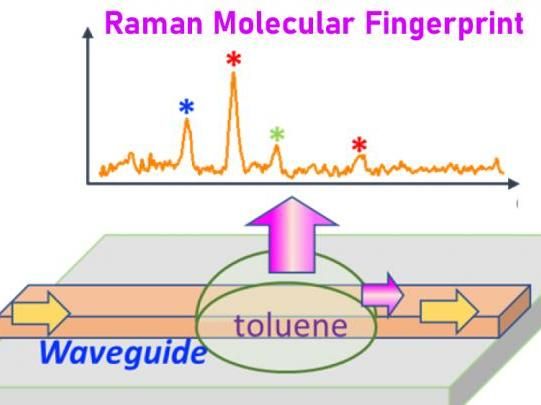

Researchers dramatically downsize technology for fingerprinting drugs and other chemicals - Tiny photonic chip could fit comfortably within the tip of a finger