Startup uses hard metal scrap to produce tungsten and tungsten carbide in the form of nanoparticles with the help of bacteria

GS Bavaria closes seven-figure seed round for scaling tungsten particles as sustainable additive in composites

Advertisement

GS Bavaria aims to support the composites industry on its way to sustainability. The startup enables users to dramatically improve mechanical properties and resource use through biologically produced tungsten-based additives. With the seven-figure financing round, led by High-Tech Gründerfonds and with the participation of renowned business angels, GS Bavaria is setting up industrial production of the nanomaterials and investing in sales and R&D.

Team of GS Bavaria

©GS Bavaria

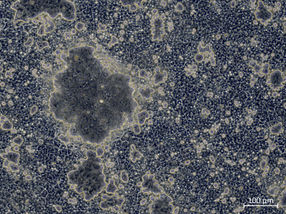

GS Bavaria uses hard metal scrap to produce tungsten and tungsten carbide in the form of nanoparticles with the help of bacteria. The process can later be used for other metals as well. The nanopowders of tungsten, tungsten carbide and – after oxidation – also tungsten oxide are made available to the plastics industry in the form of additives as masterbatches. By adding small amounts of nanomaterial, mechanical properties of composites such as strength, toughness and abrasion can be drastically improved. As a result, up to 30% of material can be saved in the production of composite components.

Both due to its production with the help of bacteria and the very significant material savings, and finally due to the recyclability of the modified composites, the tungsten-based nanomaterials are extremely sustainable. They therefore contribute to greatly improved resource efficiency and reduced carbon footprint. Other material-improving properties such as UV resistance, ionizing radiation absorption and thermal properties are added.

The startup was founded in 2020 in Nürnberg by Sergej Schmitke, who has already been working intensively on the production and application of nanomaterials since 2016. This was preceded by many years of research and development work. The current team combines many years of experience in sales to the composite industry with profound R&D, production, and management know-how.

Financing round enables establishment of production

GS Bavaria has developed the production of nanopowders and masterbatches on a laboratory scale over many years. Part of the investment will enable the establishment of industrial production in the Nuremberg area and the development of further products.

"Tungsten-containing nanopowders – that’s our specialty. And a speciality to boot. Because we obtain our nanopowders from hard metal scrap in a unique recycling process. Based on these powders, we develop functional additives in the form of masterbatches, which you can use to drastically influence the mechanical, chemical or thermal properties of your plastics. Without the compromises that come with using conventional additives", Sergej Schmitke, Founder at GS Bavaria.

"The addition of tungsten particles significantly improves the properties of polymer composites relevant to all aspects of our daily lives from drinking water to transportation. GS Bavaria was the first in the world to develop a sustainable and scalable process to produce tungsten particles. We look forward to supporting the management team in this exciting journey", Dr. Maximilian Bock, Investment Mananger at HTGF.

Other news from the department business & finance

Most read news

More news from our other portals

Something is happening in the chemical industry ...

This is what true pioneering spirit looks like: Plenty of innovative start-ups are bringing fresh ideas, lifeblood and entrepreneurial spirit to change tomorrow's world for the better. Immerse yourself in the world of these young companies and take the opportunity to get in touch with the founders.