Ammonia as a hydrogen vehicle: New integrated reactor technology for the energy transition

Disruptive process with high savings potential

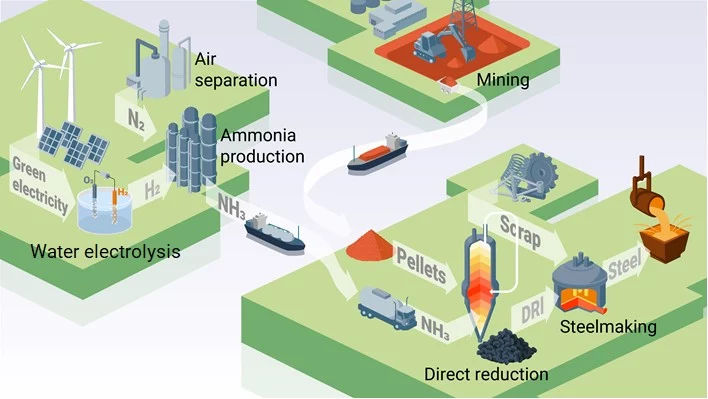

ammonia from green hydrogen is an energy carrier with high economic potential that can be used as a chemical feedstock, as marine fuel or for stationary power generation. In the future, it will be imported on a large scale from regions with high solar and wind resources. In the project "PICASO" (Process Intensification & Advanced Catalysis for Ammonia Sustainable Optimized process), the Fraunhofer Institute for Solar Energy Systems ISE, Ulm University and the Fukushima Renewable Energy Research Institute (FREA-AIST) are working on a novel power-to-ammonia (PtA) process for sustainable ammonia synthesis. The process could reduce CO2 emissions by 95 percent compared to the conventional process. The project, funded by the German Federal Ministry of Education and Research, started on August 1.

Pilot plant for the dynamic investigation of methanol synthesis on an industrial scale at Fraunhofer ISE

Fraunhofer ISE

Ammonia as a hydrogen vehicle has the potential to make a significant contribution to the energy transition: "Ammonia can also be produced from green hydrogen and nitrogen in sunny and windy but remote regions - for example in the North African desert. The energy carrier is liquefied for transport to Europe, usually by ship. For this purpose, we are developing an integrated reactor technology with dynamic operating strategies, which allows operation with fluctuating renewable energy sources," explains Prof. Dr. Christopher Hebling, Division Director Hydrogen Technologies at Fraunhofer ISE.

In contrast to the conventional Haber-Bosch process, the PtA process allows the use of more active synthesis catalysts thanks to the high purity of the electrolysis-based "green" hydrogen. These can operate at lower temperatures, which increases the thermodynamically possible ammonia yield and thus enables operation at lower pressures and without recycling of unconsumed reactants. For the project, the Japanese partner FREA-AIST has developed a novel ruthenium catalyst that enables synthesis at much milder process conditions with temperatures below 400 °C and pressures below 80 bar. This catalyst can already be produced on a semi-industrial scale (TRL > 7). In order to increase the yield even further, Fraunhofer ISE and Ulm University are investigating the integrated separation of ammonia: The reaction and the separation of ammonia take place in-situ in an integrated reactor. In this way, the operating pressure can be minimized and the recirculation of unreacted feed gas can be avoided. "Since compressors and heat exchangers are the biggest cost drivers in conventional ammonia synthesis, accounting for 90 percent of investment costs, these improvements offer enormous potential for the economic viability of flexible ammonia production plants that can also be used in remote regions," says Dr.-Ing. Ouda Salem, group leader Power to Liquids at Fraunhofer ISE. This means that complex infrastructure is no longer necessary and ammonia production can be carried out on a much smaller scale. This offers the potential to tailor the novel PtA process for the use of renewable energy sources even in remote regions. Prof. Dr.-Ing. Robert Güttel, head of the Institute of Chemical Engineering at Ulm University, adds, "We can also make much better use of hydrogen and nitrogen if no recycling is required, so we can significantly increase the material and energy efficiency of the entire PtA process. "

In the project, the transfer of the new PtA concept from laboratory to pilot plant scale is already to be realized. While the focus at Ulm University is on the laboratory scale, extensive experimental studies are being carried out in the pilot plant at Fraunhofer ISE. Robert Güttel: "The experimental findings at both scales are linked by detailed mathematical modeling and simulation. In this way, we can even already make reliable predictions for the pilot scale and accelerate the implementation of the integrated reactor concept. ". In addition to the technical demonstration, the partners also want to prove that the novel, flexible PtA process is economically competitive with the conventional process.

Disruptive process with high savings potential

"If successful, the PICASO approach will be a disruptive technology that replaces a conventional fossil process, reducing CO2 emissions by up to 95 percent," Ouda Salem said. A simulative analysis of the PICASO process has also shown a potential energy saving of 50 percent compared to the conventional Haber-Bosch process. A specific goal for a follow-up project is to scale up the integrated reactor to demonstration level and test it in a pilot plant at the site of associated partner FREA-AIST in Fukushima. In addition, the researchers are developing specific dynamic studies and operating strategies to identify interface requirements between the electrolyzers and the synthesis plant. Successful completion of these project phases will provide the basic engineering data for an industrial reference plant. The PICASO partners will accompany these phases with R&D services and their own patents on catalyst and reactor developments in order to license the complete technology to the chemical and process industries.

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.