Rare insights into growing nanoparticles

“This is a key factor for the design of highly active catalysts and sensors with high sensitivity”

Advertisement

How exactly do nanoparticles form in solution? Researchers from Universität Hamburg and DESY have now been able to observe the growth of nanoparticles in solution in real time. In the journal Nature Communications, they report on their observations using the method of X-ray ptychography, which provides a microscopic view of the dynamic processes.

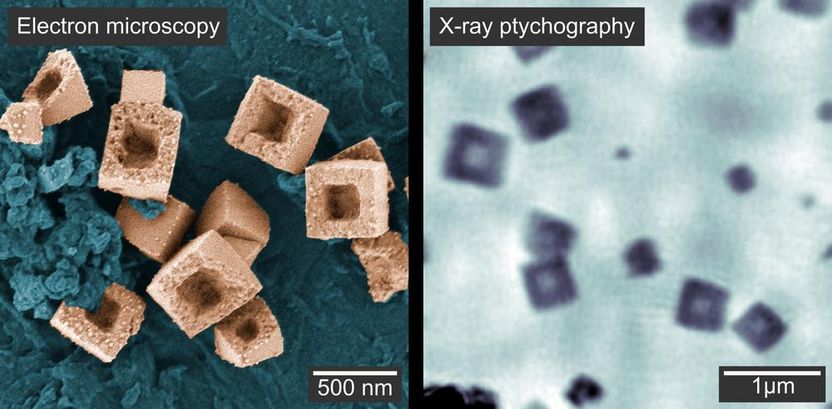

Scanning electron microscopy image (left) of the hollow copper nanocubes outside the chemical reactor. X-ray ptychography (right) does not deliver the same resolution, but can follow the growth inside the chemical reactor in real time.

Grote et al., „Nature Communications“; CC BY 4.0, link: https://creativecommons.org/licenses/by/4.0/

Hollow nanoparticles with sizes in the range of several hundred nanometers (one nanometer is one millionth of a millimeter) have widespread application potential, for instance in lithium ion batteries, as sensors and for (photo-)catalytic energy production. “To reach the desired functionality and high performance, it is decisive that we achieve precise control over the structure and shape of the nanoparticles during their growth”, explains first author Lukas Grote, doctoral student in the group of Dorota Koziej at Universität Hamburg and the Cluster of Excellence “CUI: Advanced Imaging of Matter”.

Many pathways exist that lead to complex, hierarchical materials. Due to the lack of suitable experimental methods, however, understanding and manipulating the course of the underlying changes of the nanoparticles remains a major challenge.

Microscopy techniques, which allow to follow such processes in real time, are expected to solve the problem: Liquid-cell transmission electron microscopy (TEM) can provide spatial resolution down to the atomic scale. However, its applicability to the growth of nanoparticles in solution is limited, since it requires thin reactors with small volumes which can alter the pathway. X-ray microscopy using synchrotron radiation overcomes these limitations.

Hard X-rays have the power to penetrate thick chemical reactors, while at the same time allowing to visualize growing nanoparticles at a spatial resolution as high as 10 nanometers. “The method of X-ray ptychography, in which an image is obtained computationally from the superposition of X-ray light waves oscillating in unison, extends these advantages because it gives us the ability to interpret images quantitatively," Grote explains. In this way, it is possible to conclude on the three-dimensional shape of the nanoparticles.

For their current study, the team used the experimental station P06 at DESY’s X-ray light source PETRA III together with the research group of DESY scientist Christian Schroer. “It was our aim to follow the growth of cuprous oxide nanocubes and their subsequent transformation into hollow copper structures by X-ray ptychography,” Schroer explains. The observations show that: particles growing on the reactor windows developed a flatter shape, while particles in solution took on a regular cubic shape. The nanocubes were then reduced to metallic copper in a solid-state reaction. Voids formed in the center of the particles and expanded toward the surface, resulting in hollow nanocubes.

“Such rare visual insights into structural changes in solution are important to understand where the different shapes of nanomaterials originate from,” Koziej concludes. “This is a key factor for the design of highly active catalysts and sensors with high sensitivity.” The method can be applied to a wide range of materials and reaction conditions, complementing the capabilities of liquid-cell TEM.

Researchers from Universität Hamburg, Italy's National Research Council, the University of Cambridge in the United Kingdom, Sao Paulo State University in Brazil, the Paul Scherrer Institute in Switzerland and DESY contributed to this research.

Original publication

Imaging Cu2O nanocube hollowing in solution by quantitative in situ X-ray ptychography; Lukas Grote, Martin Seyrich, Ralph Döhrmann, Sani Y. Harouna-Mayer, Federica Mancini, Emilis Kaziukenas, Irene Fernandez-Cuesta, Cecilia A. Zito, Olga Vasylieva, Felix Wittwer, Michal Odstrčzil, Natnael Mogos, Mirko Landmann, Christian G. Schroer, and Dorota Koziej; „Nature Communications“, 2022