2D boundaries could create electricity

Rice lab leads effort to generate thickness-independent piezoelectricity in atom-thick materials

There’s still plenty of room at the bottom to generate piezoelectricity. Engineers at Rice University and their colleagues are showing the way.

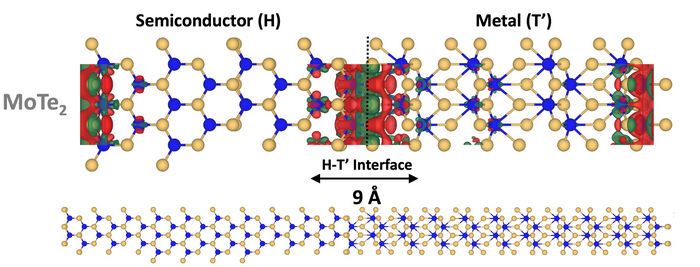

A charge redistribution model shows how charge flows across the phase interfaces in a 2D piezoelectric material of molybdenum (blue) and tellurium (yellow). The red areas are electro-deficient, the green is electron rich. Voltage from a microscope tip distorts the lattice and creates dipoles at the boundary between the atoms.

Ajayan Research Group/Rice University

A new study describes the discovery of piezoelectricity — the phenomenon by which mechanical energy turns into electrical energy — across phase boundaries of two-dimensional materials.

The work led by Rice materials scientists Pulickel Ajayan and Hanyu Zhu and their colleagues at Rice’s George R. Brown School of Engineering, the University of Southern California, the University of Houston, Wright-Patterson Air Force Base Research Laboratory and Pennsylvania State University appears in Advanced Materials.

The discovery could aid in the development of ever-smaller nanoelectromechanical systems, devices that could be used, for example, to power tiny actuators and implantable biosensors, and ultrasensitive temperature or pressure sensors.

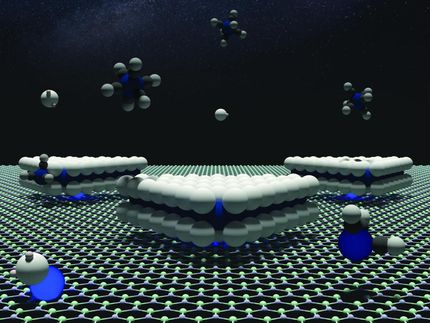

The researchers show the atomically thin system of a metallic domain surrounding semiconducting islands creates a mechanical response in the material’s crystal lattice when subjected to an applied voltage.

The presence of piezoelectricity in 2D materials often depends on the number of layers, but synthesizing the materials with a precise number of layers has been a formidable challenge, said Rice research scientist Anand Puthirath, co-lead author of the paper.

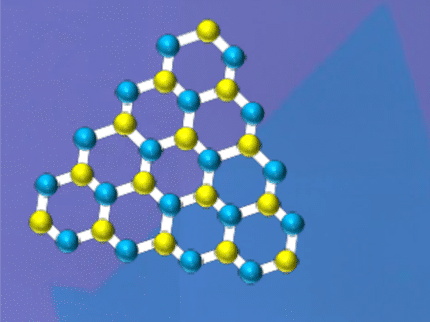

“Our question was how to make a structure that is piezoelectric at multiple thickness levels — monolayer, bilayer, trilayer and even bulk — from even non-piezoelectric material,” Puthirath said. “The plausible answer was to make a one-dimensional, metal-semiconductor junction in a 2D heterostructure, thus introducing crystallographic as well as charge asymmetry at the junction.”

“The lateral junction between phases is very interesting, since it provides atomically sharp boundaries in atomically thin layers, something our group pioneered almost a decade before,” Ajayan said. “This allows one to engineer materials in 2D to create device architectures that could be unique in electronic applications.”

The junction is less than 10 nanometers thick and forms when tellurium gas is introduced while molybdenum metal forms a film on silicon dioxide in a chemical vapor deposition furnace. This process creates islands of semiconducting molybdenum telluride phases in the sea of metallic phases.

Applying voltage to the junction via the tip of a piezoresponse force microscope generates a mechanical response. That also carefully measures the strength of piezoelectricity created at the junction.

“The difference between the lattice structures and electrical conductivity creates asymmetry at the phase boundary that is essentially independent of the thickness,” Puthirath said. That simplifies the preparation of 2D crystals for applications like miniaturized actuators.

“A heterostructure interface allows much more freedom for engineering materials properties than a bulk single compound,” Zhu said. “Although the asymmetry only exists at the nanoscale, it may significantly influence macroscopic electrical or optical phenomena, which are often dominated by the interface.”

Original publication

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Farewell to ‘forever’ – Destroying PFAS by grinding it up with a new additive - A new way to tackle 'forever chemicals'

Breakthrough in the activation of methane - Grillo-Werke AG successfully converts methane into methanesulfonic acid

New method for measuring luminescence lifetime offers breakthrough in scientific imaging - Accelerating the pace of discovery in science and industry