Materials by recipe

Powder kit for more flexibility and material diversity in 3D printing

Powder-based laser beam melting (LPPF) is probably the best-known AM process and has great potential for industrial applications. But how can the limited range of materials for this process be circumvented and the market potential further expanded? This question was addressed by the IWM of RWTH Aachen University and the Fraunhofer IFAM in the "LPBF powder kit" project funded by the AiF. The result was the development of a sustainable solution for the individual and robust processing of metal powder blends, so that the user can cover the desired material properties with a small selection of metal powders and flexibly adjust the alloys.

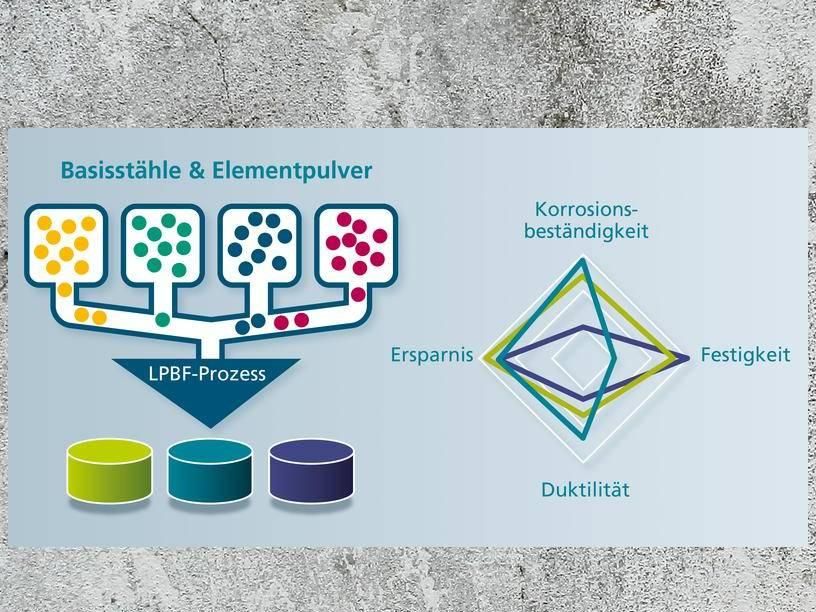

Few basic materials lead to many material property combinations. Concept of the "LPBF powder kit" for 3D printing by laser beam.

Fraunhofer IFAM

3D printing allows maximum design freedom in the construction and production of components. These advantages have enabled 3D printing technologies to become well established in technical fields such as automotive or aerospace. However, the different fields of application require not only the best possible designed geometry, but also optimized material properties. This requires an appropriately adapted material. However, research into materials for additive manufacturing is still in its infancy. So far, materials that have been qualified by equipment manufacturers for their processes have largely been processed in order to establish the various additive manufacturing processes in the industry. This range of materials is rather small and cannot be compared in terms of diversity to conventional materials, which are mostly produced by melting metallurgy. In conventional, subtractive manufacturing processes, there are hundreds of different steels, aluminum alloys, wear-resistant cobalt-chromium alloys and more for each specific application. In 3D printing, the choice across all metallic materials is limited to less than 30 materials, so not all requirements can be covered.

The right elements ensure a high diversity of material properties

The range of materials can be specifically expanded with the "LPBF powder kit", which consists, for example, of iron base powders with and without carbon, chromium, nickel, molybdenum and titanium carbide. Frequently required material properties include, for example, corrosion resistance, strength, hardness and thermal conductivity. Many steel alloys consist of the same elements such as carbon, chromium and nickel, but differ in their respective proportions. The developed process includes the selection of the alloy composition based on the specific requirement profile of the material, the determination of the powder composition using thermodynamic simulation methods, and powder preparation using adapted mixing and homogenization processes. The optimum process parameters are then determined, and the material is qualified by microstructural characterization and testing of the mechanical properties. Once the powder is mixed, the alloy is created by the subsequent laser beam melting process. The energy of the laser melts the metal powder particles and creates the desired alloy. At the end of the process stands the finished component with customized material properties.

Newly developed corrosion-resistant tool and duplex steels for 3D printing under test

The first concrete application within the project was to produce customized corrosion-resistant stainless steels for specifically adjusted property profiles by alloying in the "LPBF powder kit". During the development work, the influencing factors favoring good corrosion-resistant alloy formation were identified and the quality of the alloy was tested in an application-oriented manner. As a result, it was shown that the corrosion-resistant tool and duplex steels alloyed in the LPBF process are more resistant than the respective base powder and that they have achieved their desired target properties. Another advantage is offered by the possibility of adjusting the microstructure by means of adapted laser parameters. An example of this is the different sizes of carbides in the structure of the tool steels. Depending on the application, different sizes are required. With the developed powder construction kit, these can be efficiently varied and processed into homogeneous components. The results of this sub-project can be made available on request.

Avoiding supply bottlenecks - securing production

Companies that need to be highly flexible and supply different customers with various requirement profiles will benefit in particular from the research project. These include production service providers, most of which are small and medium-sized enterprises. The production of metal powders normally takes four weeks. If a producer wants to cover different materials with small quantities, the waiting times grow enormously. Once the basic materials have been procured, the "LPBF powder kit" can be used to set desired material properties and ensure production in the event of potential supply bottlenecks. Next development steps are the automated calculation and adjustment of the powder mixture for specific product development.