Highly sensitive quantum magnetometers on their way to industry

Quantum magnetometers for industrial use in nanoelectronics, chemical analysis and materials testing

Advertisement

Fraunhofer IAF develops quantum magnetometers based on diamond. They are able to detect magnetic fields with a spatial resolution of a few nanometers down to single electron and nuclear spins. Due to the physical material properties, diamond quantum magnetometers operate at room temperature, which is ideal for industrial applications. At this year's LASER World of PHOTONICS, the research institute is going to present two promising projects.

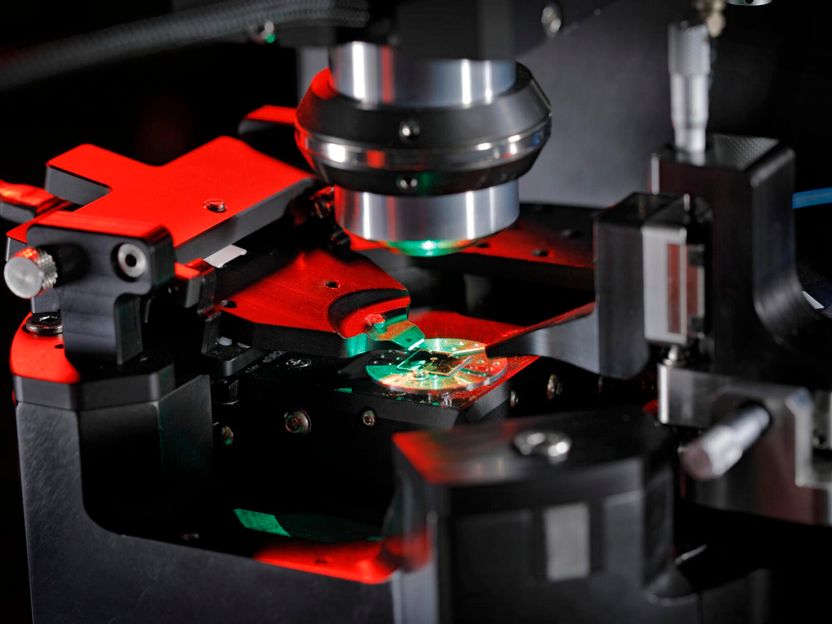

In the application laboratory quantum sensing at Fraunhofer IAF, partners from science and industry can evaluate quantum magnetometers for their specific requirements.

© Fraunhofer IAF

At present, magnetometers are only suitable for industrial use to a limited extent, as their operation is complex and in some cases only possible with extreme cooling. In addition, their spatial resolution is too low or sensitivity for many applications.

For this reason, Fraunhofer researchers from six institutes have joined forces in the Quantum Magnetometry project (QMag for short) to develop sensors that can image tiny magnetic fields with unprecedented spatial resolution, sensitivity and at room temperature. The goal of the Fraunhofer lighthouse project is to transfer quantum magnetometry from the university research environment to concrete industrial applications: By 2024, the project partners plan to realize quantum magnetometers for industrial use in nanoelectronics, chemical analysis and materials testing.

Fraunhofer research consortium

QMag is founded with a total of 10 million euros, shared in equal parts by the Fraunhofer-Gesellschaft and the federal state of Baden-Württemberg. The Fraunhofer Institute for Applied Solid State Physics IAF, the Fraunhofer Institute for Physical Measurement Techniques IPM and the Fraunhofer Institute for Mechanics of Materials IWM form the core team of the QMag consortium. Three additional Fraunhofer institutes contribute their scientific and technological competencies: The Fraunhofer Institute for Microengineering and Microsystems IMM, the Fraunhofer Institute for Integrated Systems and Device Technology IISB and the Fraunhofer Centre for Applied Photonics CAP in Glasgow.

Great progress in material development

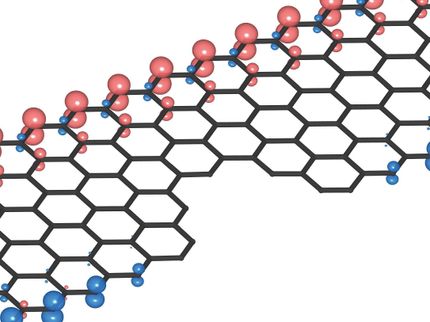

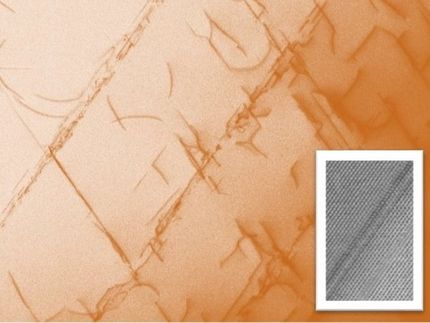

In the QMag project, two systems are being tested that are based on the same physical measurement principles and methods, but aimed different applications: On the one hand, the researchers are developing an imaging scanning probe magnetometer based on NV centers in diamond for precise measurements of nanoelectronic circuits. On the other hand, they are realizing measurement systems based on ultra-sensitive optically pumped magnetometers (OPMs) for applications in materials testing and process analytics.

“With regard to the scanning probe magnetometers, we were able to make great progress in the development and optimization of diamond sensor tips in the first half of the project,” records Dr. Ralf Ostendorf, project coordinator at QMag. This concerns both the growth of high-quality diamond and the targeted generation and placement of NV centers in the diamond tips. In addition, the researchers have developed microlenses as well as synthesized magnetic nanoparticles that are introduced into the diamond tips to further optimize them in terms of accuracy and efficiency.

Measuring the smallest magnetic fields with diamond and laser

The second research project presented by Fraunhofer IAF in the field of quantum magnetometry aims at applications in medical diagnostics:

In the project “NV-doped CVD diamond for ultra-sensitive laser threshold magnetometry“ (DiLaMag for short), a team is researching the development of an extremely sensitive sensor that can, for example, measure the weak magnetic fields of the heart and brain activities of the human body. This could be used to detect diseases at an early stage.

“Our goal is to develop an extremely sensitive magnetic field sensor that works at room temperature as well as in existing background fields and is thus practicable for clinical implementation,” explains Dr. Jan Jeske, DiLaMag project leader.

LASER World of PHOTONICS 2022

At this year’s LASER World of PHOTONICS trade fair, there will be an exhibition area dedicated to quantum technologies for the first time: In the World of Quantum (Hall A4), the participating Fraunhofer institutes IAF, IPM and IWM will present their project QMag. The joint exhibit demonstrates materials testing with OPMs.

Fraunhofer IAF will also present its research work in the field of diamond growth as well as NV-doped diamond and demonstrate the basic principle of measurement with NV diamonds.

LASER World of PHOTONICS will take place in Munich from April 26 to 29, 2022.

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.