New cutting-edge thermoplastic materials for the aerospace sector

Results from the European HITCOMP project

The Universidad Carlos III de Madrid (UC3M) coordinates the HITCOMP (High Temperature Characterisation and Modelling of Thermoplastic Composites) project within the Horizon 2020 programme, which aims to study the possible advantages of thermoplastic materials in the aerospace industry.

New cutting-edge thermoplastic materials for the aerospace sector

UC3M

The European aerospace sector typically uses low-weight, high-performance thermosetting plastic composites—also known as epoxy resin based composites—in many applications. However, these materials are not as heat resistant as other metal aircraft components, which can compromise safety in situations where extreme temperatures are reached. In an effort to improve the current thermosetting composites' behaviour in the face of heat damage, the HITCOMP research team has proposed an alternative: the use of new PAEK resins-based thermoplastic materials.

During the development of the HITCOMP project, components made from a thermoplastic base have been shown to be more efficient, from the perspective of their thermal properties, than thermosetting composites. A known property that makes them very useful is that they can be recast, reshaped, processed and recycled, without the need for any additional curing process in order to harden and set. In addition, they are more versatile, cheaper and eco-friendly materials than conventional thermosetting composites and have a longer service life, thanks to their high resilience —they can be recycled or repaired more easily— and fatigue resistance —wear and tear— and corrosion. The introduction of these materials would mean having safer and lighter aircraft which consume less fuel, improve energy efficiency and reduce their emissions.

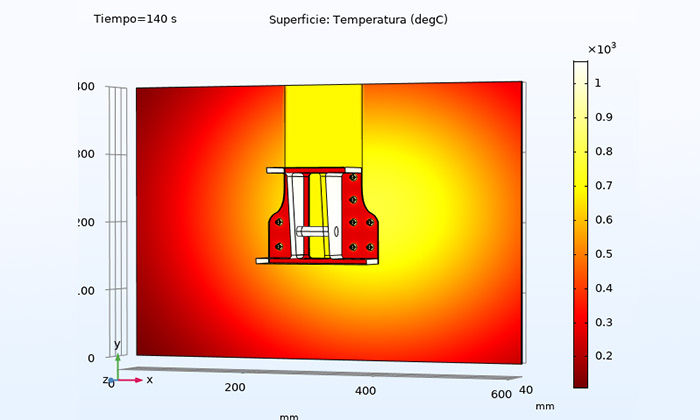

To get the most out of thermoplastics in the aerospace industry, due to their capacity to melt and deform when overheated, it is necessary to determine their behaviour when subjected to heat, fire and mechanical loads. The HITCOMP project has developed a test laboratory with new infrared (IR) thermography techniques in order to obtain accurate and non-intrusive measurements of the actual temperature of materials during fire tests. The ultimate aim is to conduct virtual tests on thermoplastics and compare their performance in real applications with those of conventional thermosetting composites.

“The aerospace sector is undergoing a transition to a more electric aircraft. This involves more heat and eventually fire sources, increasing the heating effect on the structure”, explains Fernando López, lead researcher and coordinator of the HITCOMP project, from the UC3M Department of Physics. "In this context, our project aims to establish an innovative methodology which allows a characterisation of thermoplastics that involves fewer resources and improves the prediction of their behaviour and resistance when subjected to mechanical loads or fire and high temperatures."

The measurements obtained by infrared thermography allow computer simulations to be carried out, which virtualize testing to select this type of material in the aeronautical industry. Its implementation is expected to "significantly reduce the number of validation tests, which are mandatory and greatly increase the cost and delay the approval of this type of material in the industry." The IR models and equipment have already been transferred to the Airbus company so that it can study their industrial application.

During the research process, the team has also developed a new method —inspired by the previous results of UC3M's Sensors, Remote Detection and Infrared Imaging Laboratory (LIR-InfraRed LAB)— which allows the use of these infrared imaging techniques to remotely determine the thermal properties of these materials, without contact.

Most read news

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.