Carbon molecular sieve integrated graphene sensor

New paradigm in atmospheric gas sensing and molecular identification

graphene, an atomic-thick sheet of carbon has found immense applications in gas sensors due to its single-molecule sensitivity, low-noise levels, and high carrier density. However, graphene’s much-heralded sensitivity also means it is inherently non-selective to any gas. Hence, it easily gets huge p-doping (reduction of graphene electron density) when exposed to atmospheric air which limits demonstrations of its selectivity to only inert environments such as dry air, or nitrogen. Nevertheless, for the actual commercialization of graphene in applications like environmental monitoring or breath/skin gas clinical sensors, atmospheric exposure is required. This has necessitated the desire to achieve simultaneous atmospheric passivation, and high speed & selective gas sensing in graphene. Common methods of inducing selectivity typically involve polymer coatings on graphene. However, this approach changes graphene’s intrinsic characteristics, while still exposing significant sections of the graphene channel to atmospheric doping.

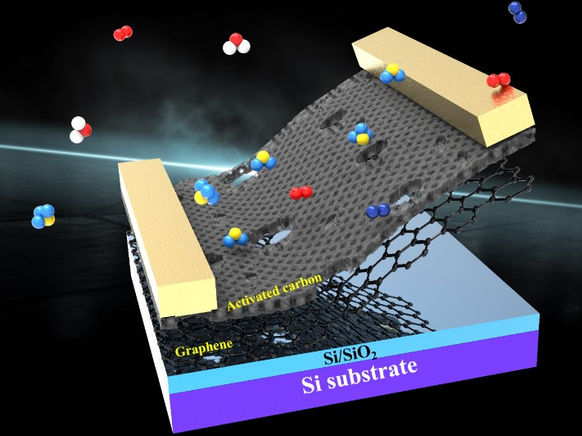

Device schematic of the activated-carbon functionalized graphene sensor with the inset showing the porous activated carbon-graphene interface.

Manoharan Muruganathan from JAIST

To achieve simultaneous atmospheric passivation, and selective gas sensing in graphene, a research team led by Dr. Manoharan Muruganathan (Senior Lecturer), and Professor Hiroshi Mizuta at the Japan Advanced Institute of Science and Technology (JAIST) developed a nano-porous activated-carbon functionalized graphene channel in collaboration with industrial partners, Mr. Hisashi Maki, Mr. Masashi Hattori, Mr. Kenichi Shimomai.

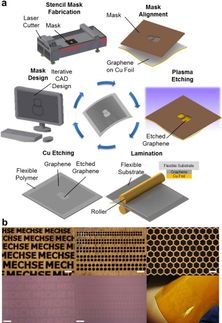

The activated-carbon functionalized Chemical vapor deposition (CVD)-graphene channel was obtained via pyrolysis of a post-lithographic Novolac resin polymer, says the researchers Dr. A. Osazuwa Gabriel and Dr. R. Sankar Ganesh. Due to the similar work-function between the activated carbon and graphene, the electronic characteristics of the CVD-graphene are retained in the sensor, with negligible atmospheric doping even after 40 minutes of atmospheric exposure. Furthermore, the oxidized activated-carbon-graphene interface defines ammonia selective adsorption sites, resulting in room temperature ammonia sensitivity of single-digit parts per billion (ppb) in atmospheric air with a few seconds response time. Consequently, molecular sieve functionality in atmospheric air was realized.

Using the same sensor, they also demonstrated a new molecular identification technique, the charge neutrality point disparity method, which utilizes the electric-field-dependent charge transfer characteristics of adsorbed gases on the graphene channel. The extreme ammonia selectivity, atmospheric passivation, as well as facile and scalable lithographic fabrication of this sensor makes it suitable for clinical and environmental sensor applications. “These results take graphene gas sensors from demonstrations in controlled environments to actual atmospheric applications, opening a new vista in graphene-based gas sensing”, says the research collaborator Mr. Masashi Hattori, Manager, TAIYO YUDEN CO., LTD.

Original publication

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.