Researchers seek to re-use waste plastics to make valuable petrochemicals

“The produced ethylene and BTX aromatics from plastic upcycling can be used as feedstocks to re-make plastics”

Despite efforts to promote recycling and reuse of plastic materials, the plastic problem continues to be a global problem. West Virginia University engineers hope to debottleneck the remaining challenges for recycling of single-use plastic packaging by upcycling them into petrochemicals.

Researchers at West Virginia University's Statler College of Engineering and Mineral Resources have received a $859,136 grant from the REMADE Institute and Braskem to increase the recycling rate of single-use plastics by converting the plastic waste into valuable aromatics that are used to create petrochemical materials.

WVU Photo

“Americans throw away 100 billion plastic bags annually, that’s about 307 bags per person,” said Yuxin Wang, research assistant professor of chemical and biomedical engineering and principal investigator of the project. “Single-use plastic waste ends up in landfills or the water, harming the ecosystem and natural environment. Most of the energy and carbon in plastic wastes will be recovered and the proposed technology will significantly reduce carbon dioxide emissions.”

Funded by a $859,136 grant from the REMADE Institute, a public-private partnership established by the U.S. Department of Energy, and Braskem, Wang, Research Assistant Professor Changle Jiang, and John Hu, professor of chemical and biomedical engineering, aim to increase the recycling rate of single-use plastics by converting plastic waste into valuable aromatics that are used to create petrochemical materials.

Petrochemicals are used to manufacture many of the goods that people use daily, ranging from medicine and cosmetics to electronics and solar panels, and furniture and appliances.

“Over the past decade, great efforts have been made to upcycle single-use plastics, especially thermochemical technologies,” Wang said. “However, all thermochemical processes suffer from severe challenges. As a result, it is difficult to achieve upcycling efficiently by these energy intensive and complex processes.”

Since the 1950s, the rate of plastic production has grown faster than any other material, with only 9 percent of plastic waste ever produced having been recycled, according to a report by the United Nations Environment Programme.

According to Wang, current technologies to upcycle single-use plastics are energy intensive, causing a high volume of greenhouse gas emissions and prohibiting large-scale upcycling.

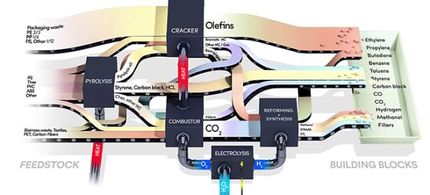

The researchers from the Statler College of Engineering and Mineral Resources will use a simple one-step microwave catalytic process to upcycle single-use plastics into high value benzene, toluene and xylene (BTX) for use as petrochemical materials. Wang explained that this will enable cross-industry reuse of recycled feedstock and reduce primary fossil fuel consumption.

In 2019, the global market for BTX aromatics reached 100 million tons per year with a value of over $100 billion per year. According to Wang, the market is predicted to reach $247 billion by 2027.

“The produced ethylene and BTX aromatics from plastic upcycling can be used as feedstocks to re-make plastics,” Wang said. “That will reduce demand on fossil fuel derived ethylene and BTX aromatics from conventional petroleum refinery, leading to a reduction in greenhouse gas emissions.”

Topics

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.