New catalysts for fuel cells

Efficient and with consistently high quality

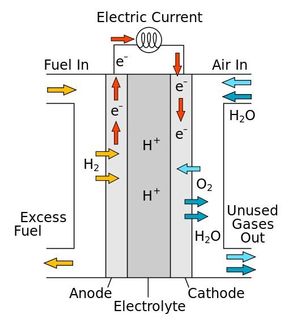

fuel cells are typically applied to generate electrical energy from hydrogen or Methanol. Nanoscale catalysts get the process going - but until now, the quality of these materials has varied significantly. The CAN research division of the Fraunhofer Institute for Applied Polymer Research IAP eliminated these problems: With an optimized catalyst and continuous, reproducible production process with very good control over the material properties.

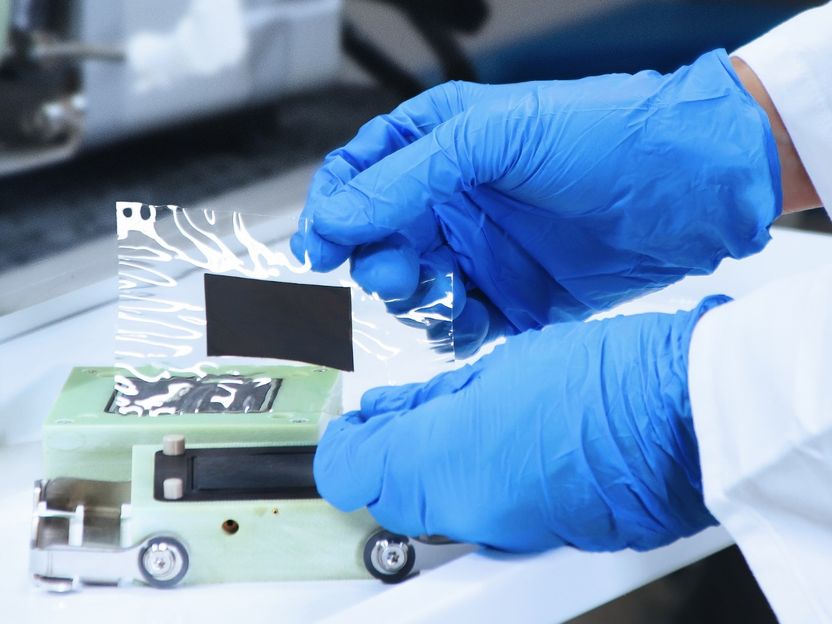

Characterization of fuel cells: A new test system enables fuel cells to be tested with the new catalysts, thus demonstrating the consistent quality of the catalyst particles.

© Fraunhofer IAP

Hydrogen is a future issue - H2 drives, for example, are intended to complement electromobility in a meaningful way. Fuel cells help to convert the chemical energy stored in hydrogen or methanol into usable electrical energy, i.e. to generate electricity. Nanoscale catalysts based on platinum are used to achieve this at manageable temperatures and with a reasonable energy input. Previous methods for their production are based on batch syntheses and allow only insufficient control over size, shape and composition of the particles. However, these parameters have a strong impact on the catalysis process. Nanoparticles are especially suitable as catalysts because they have a large surface area in relation to the amount of material used. Their use therefore saves material and thus costs. The problem is the quality of conventional catalyst materials can vary greatly.

Continuous process, reproducible product

Scientists in the Fraunhofer IAP’s research division CAN have now developed stable and efficient catalysts and optimized their production process – in the HiKAB project, short for "Hierarchical Composite Nanoparticle Systems for Application in Fuel Cells", funded by the German Federal Ministry for Economic Affairs and Energy BMWi (FKZ 03ET1435A). "We have converted the batch process into a continuous production process," says Dr. Christoph Gimmler, department head at Fraunhofer IAP. "In doing so, we rely on a bottom-up process – building up the nanoparticles atom by atom. In this way, we can not only produce nanoparticles with consistent, high quality via synthesis guidance, but also selectively adjust size, type and composition of the catalyst particles." In the reactor that the research team developed and built, this synthesis process runs continuously – especially the critical nucleation phase. What's special: The team has separated the nucleation phase spatially and temporally from the growth phase; in this way, the reaction temperatures, for example, can be well controlled. This enables very good reproducibility of the process and the properties of the material produced. The researchers have also optimized the catalyst material itself. "We have replaced part of the platinum with a less noble and thus less expensive metal," Gimmler specifies. This not only has a positive effect on material costs, but also allows the catalyst to work more efficiently and increases its service life.

The proof of concept has already been provided: The researchers have tested the produced catalysts in direct methanol fuel cells – with success. In long-term tests, they will now analyze exactly how much the new materials and the optimized production process have to offer in terms of cost savings. From initial measurement results, it is clear that the catalysts developed are also highly interesting for hydrogen fuel cells.

Analyzing materials at the systemic level

So far, the catalyst materials developed by the research team in the HiKAB project could only be tested electrochemically. In the ProkAB project, short for "Processing and Characterization of Catalytically Active Nanoparticles for Application in Fuel Cells," which is funded by the Authority for Science, Research, Equality and Districts (BWFGB), the Fraunhofer IAP has therefore now established a fuel cell test rig for routine measurements. "We have expanded our characterization spectrum and are now able to test the materials we develop at the fuel cell level," Gimmler reports. "This allows us to perform the litmus test, so to speak – after all, even more parameters play a role at the system level than in the laboratory." The Fraunhofer IAP thus offers expertise not only in materials development but also in the characterization of fuel cells.

Organizations

Other news from the department science

These products might interest you

NANOPHOX CS by Sympatec

Particle size analysis in the nano range: Analyzing high concentrations with ease

Reliable results without time-consuming sample preparation

Eclipse by Wyatt Technology

FFF-MALS system for separation and characterization of macromolecules and nanoparticles

The latest and most innovative FFF system designed for highest usability, robustness and data quality

DynaPro Plate Reader III by Wyatt Technology

Screening of biopharmaceuticals and proteins with high-throughput dynamic light scattering (DLS)

Efficiently characterize your sample quality and stability from lead discovery to quality control

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.