Simple creation of a super multi-element catalyst homogeneously containing 14 elements

Realization of omnipotent catalysts expected

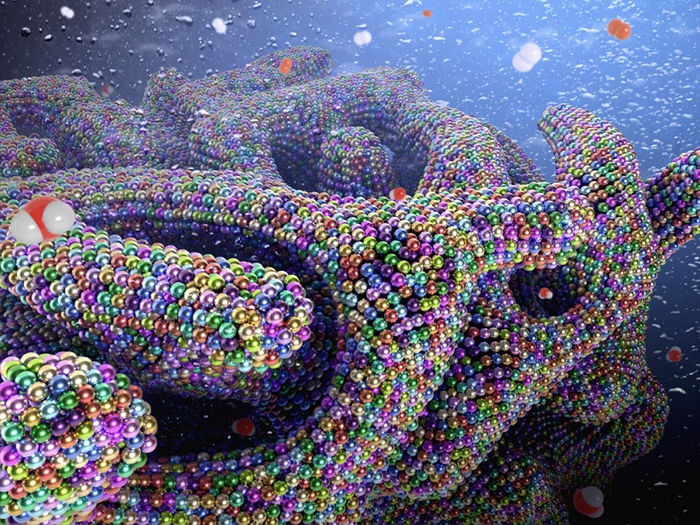

A research group in Japan has successfully developed a “nanoporous super multi-element catalyst” that contains 14 elements which are mixed uniformly at the atomic level and used as a catalyst. A high-entropy alloy composed of 10 or more elements may act as a catalyst to exhibit" omnipotency and versatility" being able to freely modify its morphology and become active according to the reaction field. However, so far, it has not been easy to produce entropy alloys composed of more than 10 elements. The reason is the existence of combinations of some elements that are hard to be mixed, like water and oil.

The nanoporous super multi-element catalyst promotes the water splitting from water to hydrogen and oxygen.

Takeshi Fujita

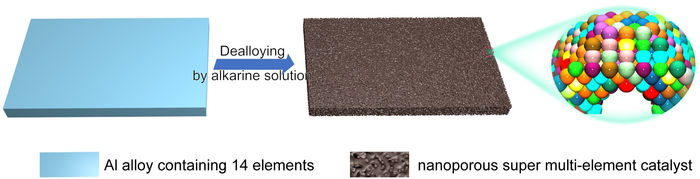

The nanoporous super multi-element catalyst can be made from an Al alloy containing 14 elements dealloyed by an alkaline solution such as NaOH.

Takeshi Fujita

A joint research group led by Research Associate Cai ZeXing and Professor Takeshi Fujita at School of Environmental Science and Engineering, Kochi University of Technology, and Professor Masahiro Miyauchi at School of Materials Science and Engineering, Tokyo Institute of Technology has developed a “nanoporous super multi-element catalyst” by a method called de-alloying via the selective corrosion and elusion of a specified element from the alloy. The fabrication method is simple: an aluminum alloy containing 14 elements is prepared, and the nanoporous super multi-element catalyst is manufactured by preferential dissolution of aluminum using an alkaline solution. It has been found that, by using this method, while creating a nanoporous structure with a large specific surface area (surface area per unit mass of material) with a pore size of about 5 nanometers, elements other than aluminum that do not dissolve in the alkaline solution are accumulated to be aggregated in the form of a solid solution alloy in which the 14 elements are uniformly distributed at the atomic level.

Further, the nanoporous super multi-element catalyst was found to show excellent properties as an electrode material for water electrolysis due to the multi-element superposition effect (cocktail effect). As this catalyst contains many different elements, it is expected to be developed into an omnipotent and versatile catalyst in the future.

Original publication

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.