Unexpected twist of catalytic nanoparticles

Precise orientation affects shape, size and behaviour

nanoparticles that make up catalysts can arrange themselves in slightly different ways, and behave significantly differently as a result. This is revealed by an X-ray study of palladium nanoparticles carried out at DESY Nanolab and PETRA III. The study has been published in the journal ACS Nano and provides systematic insights into the self-organisation of such catalyst particles.

The particle in preferred orientation (right) and the slightly twisted one (left) differ in shape and thus in function.

DESY, Vedran Vonk

Catalysts often consist of certain metals, such as platinum, rhodium or palladium, which promote the desired chemical reactions without being consumed themselves. The catalytic converters used in the exhaust system of cars, for instance, promote the oxidation of toxic carbon monoxide to carbon dioxide and the reduction of harmful nitrogen oxides. The metals usually take the form of nanoparticles, because these have larger surface areas for a given amount of material.

More active centres of the catalyst nanoparticles are often located at corners and along edges. The shape and size of the particles can therefore have a substantial influence on their function and efficiency. However, scientists are only just beginning to understand exactly how these things are connected and how the structure of the nanoparticles can be controlled.

“In many cases, the exact details of the structure and function of catalysts are still shrouded in mystery,” explains DESY’s Vedran Vonk from the Nanolab. “If we knew the optimal size and shape of a nanoparticle, for example, catalysts could be made significantly better and cheaper. In particular, the role of the particles’ precise orientation on the substrate has scarcely been explored. We assume that around 90 percent of the metal used in present-day catalysts contributes nothing to their functionality.”

For its systematic study, the DESY team grew palladium nanoparticles on a magnesium oxide substrate. “Both these materials are typically found in a range of different catalysts, so the system we studied can serve as a model for numerous applications, including the catalytic converters installed in cars,” points out the lead author Simon Chung from DESY Nanolab. The researchers analysed size and orientation of the resulting nanoparticles using high-intensity X-rays from PETRA III. “It clearly emerges that the nanoparticles have a preferred orientation,” reports Dmitri Novikov, head of the P23 beamline at which the experiment was carried out. “They line up along the crystal lattice of the magnesium oxide substrate and almost all of them grow in a certain direction and to a certain size.” But only almost all of them: about one in a hundred nanoparticles aligns itself at a small angle to the preferred direction.

“That came as a surprise: in addition to the main orientation, there is a second preferred direction, rotated by just 3.7 degrees to the right or left of the main direction,” explains Jan-Christian Schober, who wrote his master's thesis on this topic at the University of Hamburg. “About one percent of the particles adopt this second alignment and their shape is also slightly different.” As a result, the corners and edges with the active centres also differ in the two types of particles, and they behave differently when in operation catalytically.

The team simulated the practical operation by heating the particles to more than 400 degrees Celsius and investigating their shape in oxidation and reduction reactions. During these reactions, the nanoparticles typically change their shape, which in turn means that the active sites shift. The operational data for the two types of nanoparticles differ considerably, but in view of the complexity of their interaction it is not yet possible to give a simple answer as to which type of particle works better.

“If we knew the positions of all the atoms and, in addition, how each individual atom contributes to the catalytic effect, we would be able to tailor the optimal catalyst for every application,” says Vonk. At the moment, that is not possible. A new collaborative research centre called “Tracking the Active Site in Heterogeneous Catalysis for Emission Control” (TrackAct)", involving scientists from DESY and the Karlsruhe Institute of Technology (KIT), wants to explore exactly this question. Studying the palladium nanoparticles is itself the first step along this path. “We assume that on a qualitative level our observations apply quite generally to catalytic nanoparticles on a substrate,” emphasises Vonk.

Original publication

Other news from the department science

These products might interest you

NANOPHOX CS by Sympatec

Particle size analysis in the nano range: Analyzing high concentrations with ease

Reliable results without time-consuming sample preparation

Eclipse by Wyatt Technology

FFF-MALS system for separation and characterization of macromolecules and nanoparticles

The latest and most innovative FFF system designed for highest usability, robustness and data quality

DynaPro Plate Reader III by Wyatt Technology

Screening of biopharmaceuticals and proteins with high-throughput dynamic light scattering (DLS)

Efficiently characterize your sample quality and stability from lead discovery to quality control

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Nanotribology

Regional Centre of Advanced Technologies and Materials - Olomouc, Czechia

Ylang-ylang

Nernst_effect

JULABO acquires automation expert GAF

Skattebøl_rearrangement

New Measurement Device: Carbon Dioxide As Geothermometer - Researchers quantify rare CO2 variants using laser spectroscopy

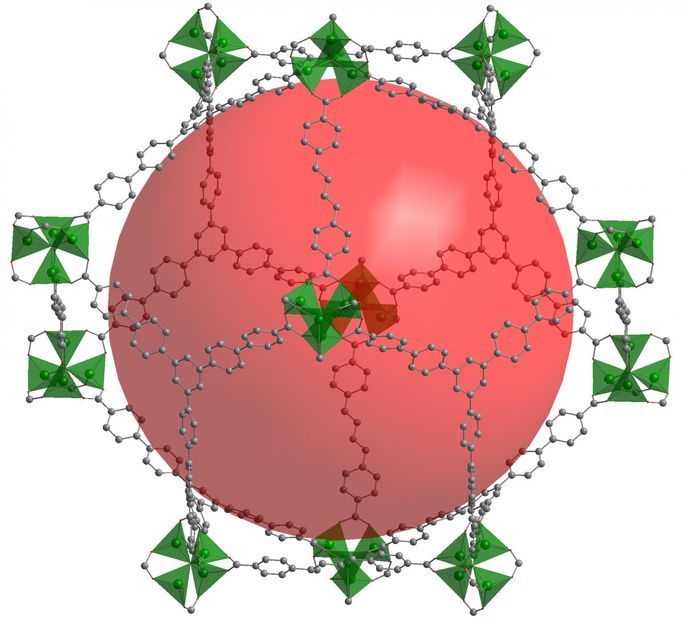

A highly porous material, more precious than diamonds

BASF confirms ambitious climate targets and takes steps to reduce product-related emissions - 25 percent reduction of CO2 emissions by 2030 compared with 2018 and net zero by 20501 targeted

BASF invests in industrial artificial intelligence company - Additional partnership to bring together expertise in mineral processing, ore beneficiation chemistry and industrial AI technology