Automated chemical synthesis: reliable production and rapid knowledge gain

KIT Invests About Four Million Euros in Facility for Automated Synthesis

One of the most modern infrastructures for automated process control in chemistry is being built by the Karlsruhe Institute of Technology (KIT) together with BASF: The facility will initially produce new substances in parallel for applications in fields ranging from biology to materials science. In the long term, the facility will also enable a high-throughput process for chemical reactions. KIT is investing about four million euros in this project. The facility is located in the Karlsruhe Nano Micro Facility (KNMFi) and is open to internal and external scientists.

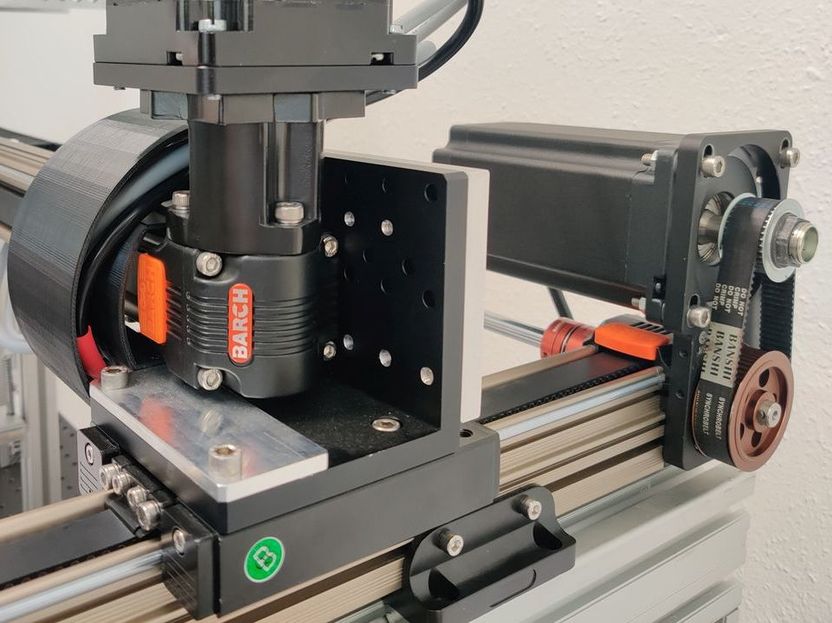

The automated plant will produce new materials for drug discovery and materials science through a combination of established equipment and open hardware components.

Foto: Patrick Hodapp, KIT

The development of automated facilities for chemical reactions to produce new materials for various applications in biomedicine, pharmaceuticals, electronics and many other fields is the goal of scientists worldwide. "Such synthesis plants allow chemical reactions to be carried out in a reproducible and standardized manner thanks to automated processes without exposing humans to chemicals," explains Professor Stefan Bräse, director at KIT's Institute of Biological and Chemical Systems (IBCS). "In addition, automated processes increase the throughput of reactions and thus the efficiency of research projects. This leads to new findings more quickly. “

Over the next two years, KIT will invest around four million euros in the development of a plant for the automated synthesis of new chemical substances.. The facility will be located at KNMFi to provide interested internal and external researchers with permanent access to one of the most modern infrastructures for automated process control in chemistry. As a strategic partner, BASF will run projects in the facility to identify for example new active ingredients for agriculture.

Modular design facilitates future expansions

This project combines several projects prepared by researchers in the working group of Professor Stefan Bräse and other KIT scientists. Wherever possible, the system will integrate components of free hardware and software to enable transparent development and later use also by other researchers. In addition, the individual components of the system will be assembled in a modular way so that future extensions can be realized in an uncomplicated way. KIT is involved in various consortia of the National Research Data Infrastructure (NFDI), especially also in NFDI4Chem, which specializes in chemistry. Close coordination with the consortia and implementation of the software and standards developed in NFDI4Chem within the facility will ensure long-term sustainable research and promote the provision of research data according to established best practice models.

Process control, robotics, software development and design work together

Initially, the synthesis plant will be geared to projects in organic synthetic chemistry: It will produce small organic molecules on a scale of around ten milligrams to several hundred milligrams, for example for chemical intermediates or active pharmaceutical ingredients. In the future, however, the facility will also be able to be used flexibly and carry out reactions on a small scale so that researchers can investigate many reactions simultaneously in a parallelized process. For both use cases, BASF brings extensive expertise to the project as it is already running an automated, high throughput platform at its global headquarters in Ludwigshafen, Germany. "We are very much looking forward to working with the KIT groups involved" says Andy Wieja, Team Leader Combinatorics & Thermal Characterization at BASF. "The development of new technologies at KIT will provide new impulses for synthesis projects and process automation at BASF to accelerate research and development for future innovations. “

The project brings together experts in process control, robotics, software development and design to combine state-of-the-art technologies and established processes. Further partners from research as well as from industry are welcome.

Most read news

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.