WACKER Presents Innovation Award for Novel Manufacturing Process for Polymer Dispersions

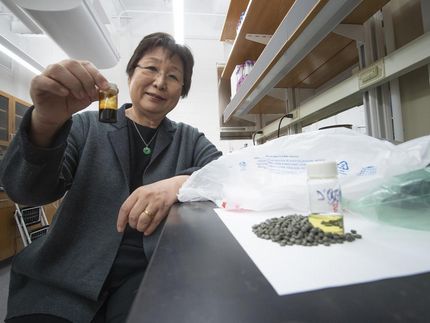

WACKER has presented an in-house German-Chinese team with the 2021 Alexander Wacker Innovation Award for developing and launching a novel process for producing vinyl acetate-ethylene (VAE) polymer dispersions. The team – consisting of Henry Chen, Zhong Chen, Dr. Bernhard Eckl, Wilhelm Kaiser, Nelson Wang and Dr. Hans-Peter Weitzel – managed to intensify the VAE process and set new standards for product throughput and energy consumption. WACKER presented the €10,000 innovation award today at its Innovation Days. Due to the coronavirus pandemic, the research symposium was an online event.

“Thanks to this pioneering approach, our WACKER POLYMERS division has strengthened its technological leadership as a manufacturer of high-quality VAE-based polymer dispersions,” explained WACKER’s Auguste Willems, Executive Board member responsible for R&D. “By selecting process conditions skillfully and by developing a novel system to optimize heat dissipation, the team has improved process efficiency beyond previously known limits. At the same time, production-process sustainability has risen markedly.”

The German-Chinese project group’s innovative approach to improving emulsion polymerization prevailed against strong competition from 34 other development teams from Germany, the USA, South Korea and India that all submitted projects for this year’s Alexander Wacker Innovation Award.

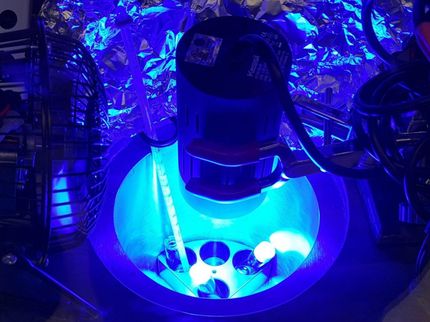

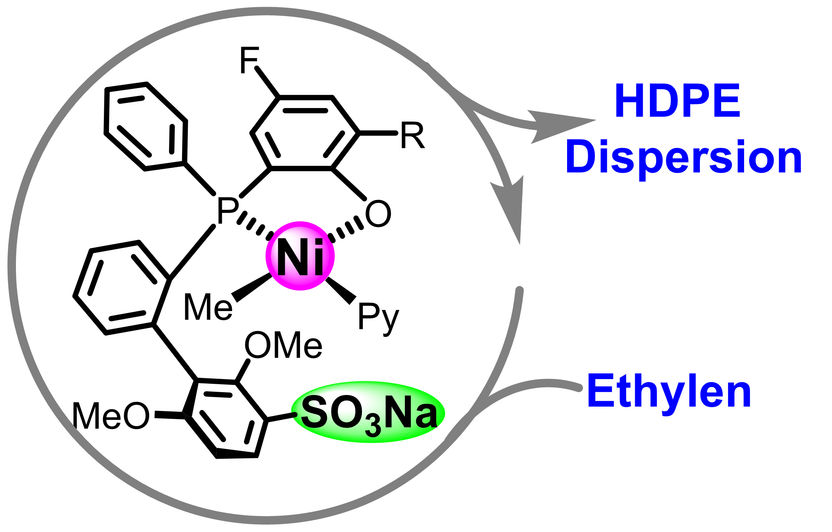

The emulsion polymerization of VAE is one of WACKER POLYMERS’ core processes. The free-radical polymerization process releases large amounts of heat that must be dissipated efficiently and effectively. The new set up makes it possible to produce VAE polymers with well-known and excellent application characteristics while lowering energy consumption and greatly increasing throughput. Based on years of experience and the use of modern simulation methods, development outputs could be directly and effectively transferred to an industrial-scale system without pilot testing.

“The winners of the Alexander Wacker Innovation Award have once again shown that outstanding technical know-how coupled with interdisciplinary cooperation between chemical-product development, engineering departments and production are the key success factors for efficiently developing and implementing sustainable production processes,” said Auguste Willems.

About the Alexander Wacker Innovation Award

Since 2006, the Munich-based WACKER chemical group has honored its employees’ outstanding R&D work at its annual research symposium. Named after the company’s founder, the €10,000 Alexander Wacker Innovation Award is conferred for outstanding performance in product innovation, process innovation and basic research.

Most read news

Topics

Organizations

Other news from the department business & finance

These products might interest you

Eclipse by Wyatt Technology

FFF-MALS system for separation and characterization of macromolecules and nanoparticles

The latest and most innovative FFF system designed for highest usability, robustness and data quality

HYPERION II by Bruker

FT-IR and IR laser imaging (QCL) microscope for research and development

Analyze macroscopic samples with microscopic resolution (5 µm) in seconds

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.