TPU scientists offer scalable technology to obtain polytetrafluoroethylene membranes

"The main advantage of the method is that the small laboratory installation is not different from an industrial one by its core and processes."

Advertisement

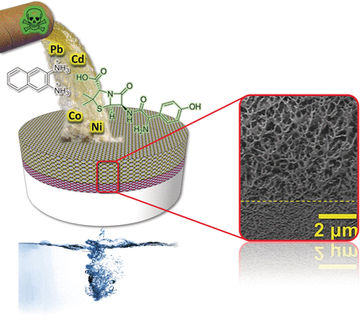

Scientists of Tomsk Polytechnic University were able to obtain polytetrafluoroethylene (PTFE) membranes using electrospinning. PTFE is known to be the most stable existent polymer. According to the scientists, it is a simple, affordable and easily scalable method, which will allow obtaining chemically stable membranes in industrial-scale production. The membranes can be used in petrochemical, aerospace, nuclear industries, carbon-free energy and medicine.

The latest results of the research of physical and chemical properties and biocompatibility of the obtained membranes are published in the Journal of Fluorine Chemistry. The obtained membranes were tested using cells and laboratory animals. The research confirmed that the membranes are not rejected by the cells and are not destroyed in the biological matrix. The interdisciplinary team consisting of physicists and chemicals is currently conducting the research at TPU.

"The material and methods of work with it were noteworthy for us. PTFE is a polymer containing fluorine. Fluorine and similar compounds are called fluoropolymers. They are noteworthy for scientists and experts working at industrial enterprises due to their inert. Fluoropolymers can be used in corrosive media or where material stability is crucial. These either can be hydrogen fuel cell operating in the conditions of corrosive media or a medical implant inside a human body. It means that obtaining membranes is very perspective, however, there is no large capacity technology in the world yet. It is either expensive or labour-intensive, even if the raw material is affordable," Evgeny Bolbasov, Research Fellow of the TPU Butakov Research Center, says.

The TPU scientists used electrospinning. It is drawing charged threads of polymer solutions under the effect of an electric field. The result is a knitted material of polymer threads.

"The main advantage of the method is that the small laboratory installation is not different from an industrial one by its core and processes. Everything that can be done in the laboratory is easily reproducible at the enterprise. Previously, it was believed that obtaining a PTFE membrane using electrospinning is simply impossible. PTFE is not pulled into threads. To solve this problem, we added polyvinyl alcohol (PVA), a crosslinking agent in the synthesis chain," the scientist says.

The process of obtaining the membrane described in the article carries two stages. First, very fine powder is mixed with PVA. A solution loading in the electrospinning installation is obtained. The thinnest threads are pulled inside of the electrospinning installation and the white porous bed is spun from these pulled threads. It is the membrane. At stage two, the membrane is fired in an oven at about 400°?. The added PVA completely evaporates in the oven and the membrane is getting dark a bit. The entire process takes no longer than three hours.

The researchers note that all raw materials used for the synthesis are commercially affordable and are produced in Russia.

These membranes possess a wide range of potential application. Only a scalable technology is required. Industrial methods of obtaining membranes from fluoropolymers are searched in Europe, the USA, China. Meanwhile, the Russian scientists possess an opportunity to offer a commercially interesting solution. From our point of view, electrospinning is such a solution.

This method is dozen folds cheaper than its alternatives, it allows easily controlling the pore structure of the membranes. Moreover, this method is reproducible and scalable, which is very interesting for potential industrial partners," Vyacheslav Buznik, an academician of the Russian Academy of Sciences, one of the article authors, says.

"Currently, the main task of the TPU researchers is to show the method opportunities for solving specific applied problems. The task is complicated, complex. It can be solved only by interdisciplinary teams consisting of materials specialists, chemists, physicists. It is crucially important for us that there are all the required experts and competences at TPU. It will help us to actively develop this field," Marina Trusova, Director of the TPU Research School of Chemistry and Applied Biomedical Sciences, notes.